- Joined

- Aug 20, 2014

- Messages

- 152

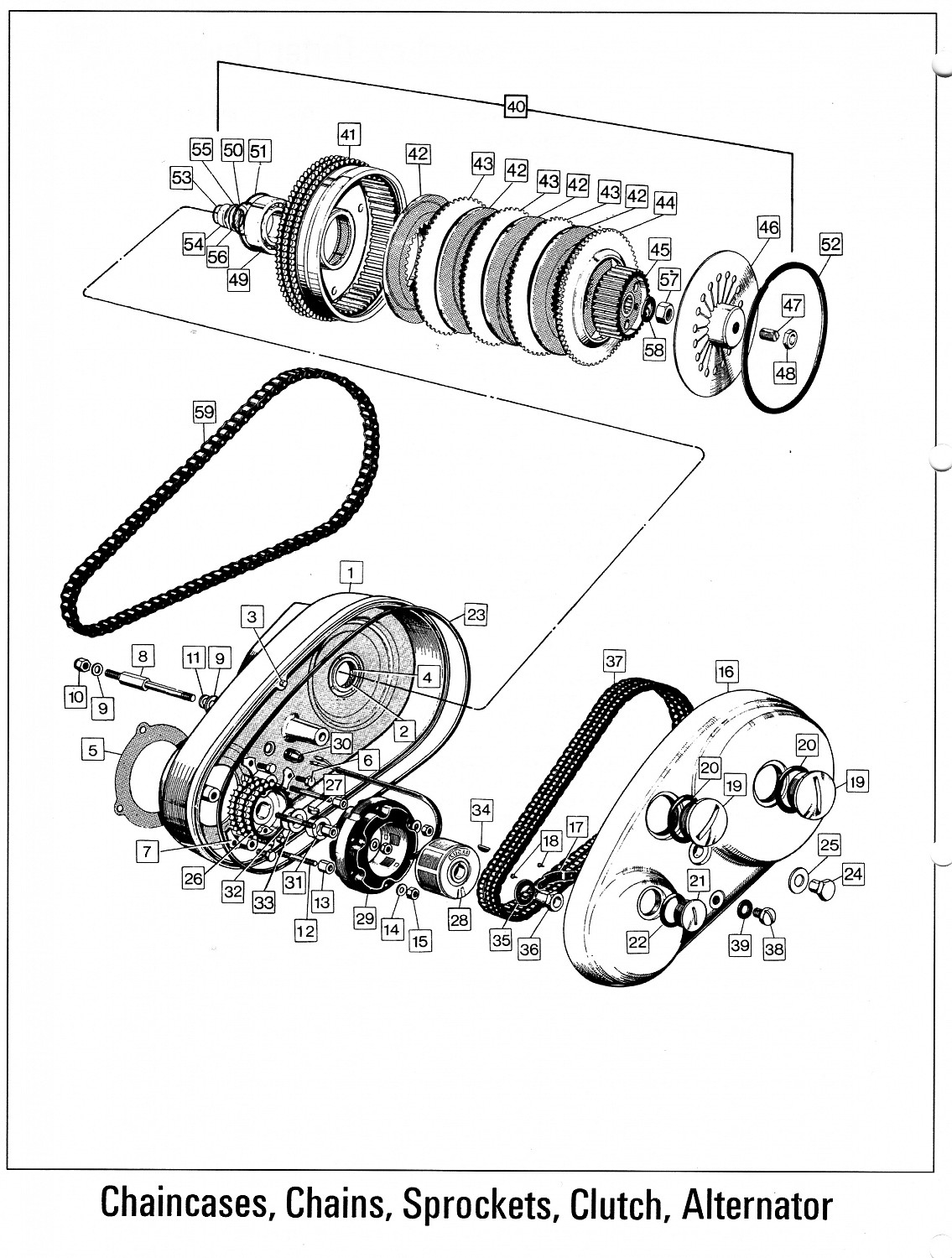

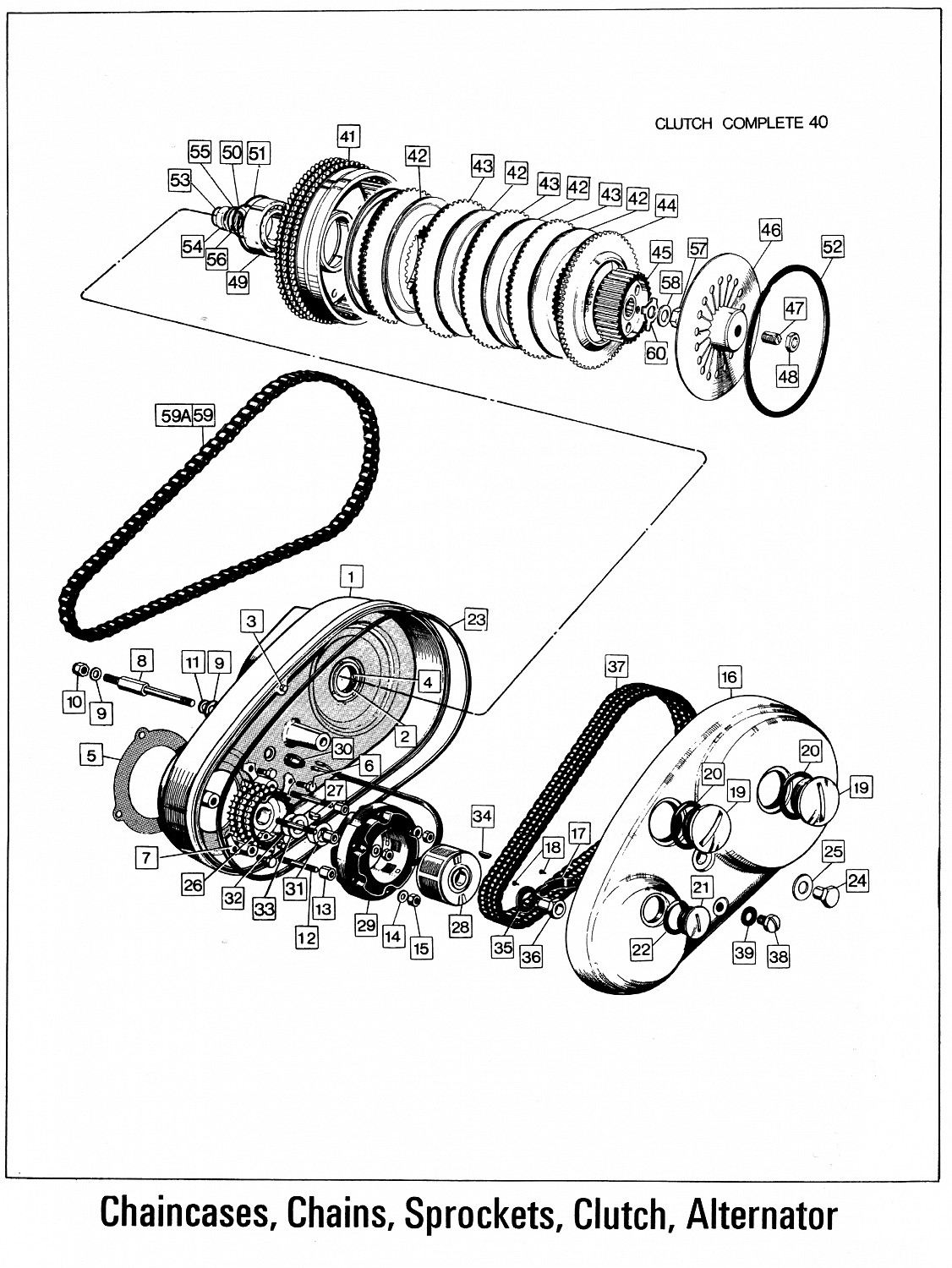

I've just stripped down the clutch in order to investigate continual loss of clutch pushrod adjustment, start out with normal amount of play at the lever and after a few miles it would have too much and drag. Figured it would either be at the clutch actuation end (as I've had the slotted ring come loose last summer) or possibly a loose mainshaft clutch nut, or possibly a soft pushrod?

Sure enough, the clutch actuation was all in order (I invested in the proper tool to tighten this) and the clutch centre was loose on the mainshaft, no apparent harm done.

My concern is there is approx 1mm radial play at the edge of the hub, between the splines on the hub and mainshaft, is this normal and/or acceptable? A search has revealed very little, threads tend to refer to play (wobble) in the hub bearing , which seems fine in mine.

I am (overly?) sensitive to this as I've just completed a clutch rebuild on my BSA Rocket Three, and detected similar levels of play between the clutch and shock absorber in that. This is pretty common on BSA/Triumph triples, but is considered less than desirable as it can cause shock absorber nuts to come loose (effectively the same issue as in my commando) ! I am trying Loctite 660 Quick Metal as some people have had success with it.

However, there was no lock-washer on the clutch nut in the commando, so that didn't help. My question is, how much, if any, play is acceptable. The hub itself is relatively unworn otherwise and everything else is in good order, the previous owner did a very extensive, high quality rebuild. I have now way of knowing, but I doubt the loose nut would have caused the spline wear that quickly, have only done a few short journies with this issue apparent?

I'll be doing a more extensive primary rebuild this winter when I fit a belt drive, but would rather just ride whilst the weather is good.

P.s. I'm well aware of the issues around the locating circlip behind the hub and the need to reduce the torque values on the nut and augment with blue loctite.

Thanks for any advice on this.

Sure enough, the clutch actuation was all in order (I invested in the proper tool to tighten this) and the clutch centre was loose on the mainshaft, no apparent harm done.

My concern is there is approx 1mm radial play at the edge of the hub, between the splines on the hub and mainshaft, is this normal and/or acceptable? A search has revealed very little, threads tend to refer to play (wobble) in the hub bearing , which seems fine in mine.

I am (overly?) sensitive to this as I've just completed a clutch rebuild on my BSA Rocket Three, and detected similar levels of play between the clutch and shock absorber in that. This is pretty common on BSA/Triumph triples, but is considered less than desirable as it can cause shock absorber nuts to come loose (effectively the same issue as in my commando) ! I am trying Loctite 660 Quick Metal as some people have had success with it.

However, there was no lock-washer on the clutch nut in the commando, so that didn't help. My question is, how much, if any, play is acceptable. The hub itself is relatively unworn otherwise and everything else is in good order, the previous owner did a very extensive, high quality rebuild. I have now way of knowing, but I doubt the loose nut would have caused the spline wear that quickly, have only done a few short journies with this issue apparent?

I'll be doing a more extensive primary rebuild this winter when I fit a belt drive, but would rather just ride whilst the weather is good.

P.s. I'm well aware of the issues around the locating circlip behind the hub and the need to reduce the torque values on the nut and augment with blue loctite.

Thanks for any advice on this.