- Joined

- Mar 11, 2021

- Messages

- 1,411

Hi,

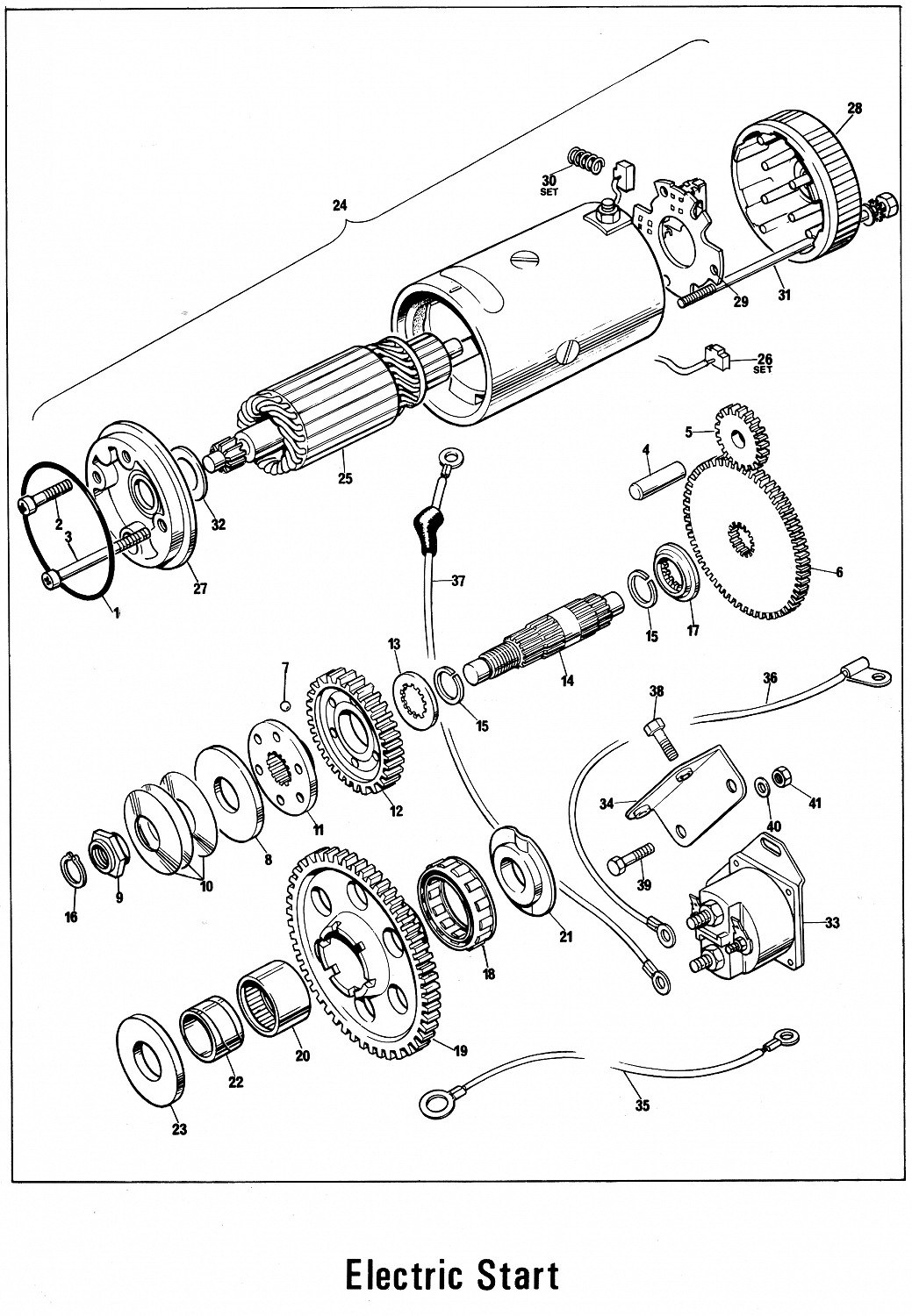

I now have a few hundred miles on my new, to me, 850 Mk3. About 500 miles ago, the PO had a new sprag clutch and sprocket etc. I assume there was a failure. Lately, first start with the button, I just get a whirring. No clacking or grinding, just a spinning. Then it catches second attempt. It's also fine if I ease the motor past compression with the kickstart. I also have a healthy weep from the rear / bottom of the primary seal. I researched the primary and starter threads on here.

I drained the oil, it was dark, with a fine metallic content. Also, well below the drian plug level. I'd say c.200cc was in there. Being the hydraulic primary chain tensioner version, I think it should have more oil (to the level screw). Also the triplex primary chain looked quite slack. Just off the chaincase. I'm assuming that's because the hydraulic tensioners had bled down?

I am thinking:

- The anti backfire may not quite be torqued-up enough, causing the starter to slip;

- The metallic oil may be due to the previous sprag failure;

Reasonable?

I cleaned everything out. Read the Old Brits article on the anti-backfire adjustment, which put me off a bit. I don't weld and so don't have access to a tool for checking the backfire device torque setting. For the moment I've put a new (AN) gasket on, with Wellseal and put in enough oil to the level plug, leaving it a couple of hours, to make sure it wasn't still weeping (just over 300cc). I plan to run it for a hundred miles or so and then drop the oil again, to see if it is clean. I'm hoping there's nothing more sinister. Does that seem sensible?

I know the starter problem won't disappear on it's own, but want to solve one concern at a time. Assuming I'll still have the starter slipping problem, does the anti-backfire seem a sensible cause? How do you adjust yours to get it right? As I understand it, it is the nut on the spindle inside the alternator stator, that I need to adjust (tighten a touch)? Can I do this leaving the stator and everything in place in the Primary?

Thanks,

Martin

I now have a few hundred miles on my new, to me, 850 Mk3. About 500 miles ago, the PO had a new sprag clutch and sprocket etc. I assume there was a failure. Lately, first start with the button, I just get a whirring. No clacking or grinding, just a spinning. Then it catches second attempt. It's also fine if I ease the motor past compression with the kickstart. I also have a healthy weep from the rear / bottom of the primary seal. I researched the primary and starter threads on here.

I drained the oil, it was dark, with a fine metallic content. Also, well below the drian plug level. I'd say c.200cc was in there. Being the hydraulic primary chain tensioner version, I think it should have more oil (to the level screw). Also the triplex primary chain looked quite slack. Just off the chaincase. I'm assuming that's because the hydraulic tensioners had bled down?

I am thinking:

- The anti backfire may not quite be torqued-up enough, causing the starter to slip;

- The metallic oil may be due to the previous sprag failure;

Reasonable?

I cleaned everything out. Read the Old Brits article on the anti-backfire adjustment, which put me off a bit. I don't weld and so don't have access to a tool for checking the backfire device torque setting. For the moment I've put a new (AN) gasket on, with Wellseal and put in enough oil to the level plug, leaving it a couple of hours, to make sure it wasn't still weeping (just over 300cc). I plan to run it for a hundred miles or so and then drop the oil again, to see if it is clean. I'm hoping there's nothing more sinister. Does that seem sensible?

I know the starter problem won't disappear on it's own, but want to solve one concern at a time. Assuming I'll still have the starter slipping problem, does the anti-backfire seem a sensible cause? How do you adjust yours to get it right? As I understand it, it is the nut on the spindle inside the alternator stator, that I need to adjust (tighten a touch)? Can I do this leaving the stator and everything in place in the Primary?

Thanks,

Martin