- Joined

- Nov 26, 2009

- Messages

- 3,415

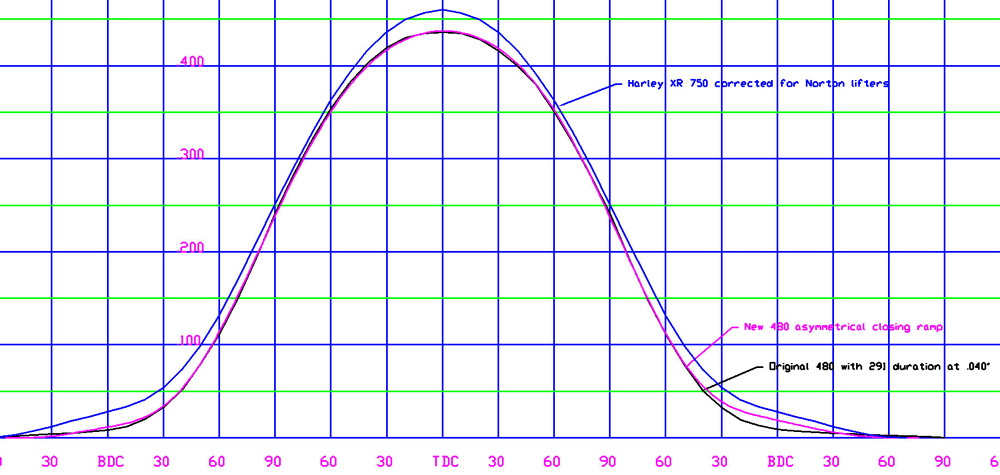

The biggest cam you can get for a Norton is the Sifton 480

It has .435” lobe lift. Some are afraid to use it because it puts so much stress on the valve train. Flank acceleration is very high and cannot be avoided without stretching the duration too far. You can’t increase the spring pressure too much or you will only put more wear on the valve train. But you can reduce the closing jerk so the valves won’t crash down too hard and cause destructive valve bounce. This will enable it to revv higher than the original 480 while still avoiding valve clash. The idea is too build a high output 9000 RPM 750 short stroke land speed racer.

I don’t know if there is anything you can do to get such a cam to revv so high but we will try. Other cam designs have incorporated the smooth ramps and will revv to 9000 but they don’t have as much lift or acceleration as the 480. Too much spring pressure would again add strain to the mix. A tapered spring with about 150 lbs seat pressure will be used. But heavier large diameter valves with add to the problem. Heavy stock Norton lifters are out of the question. Lightweight BSA lifters will be used because this is what the cam was originally designed for (and Triumph lifters) and the lighter weight will help with valve control.

Its an asymmetrical profile with a closing ramp that is longer than the opening ramp.

The numbers are being sent off to the cam grinder and the new cam will have to prove itself on the dyno.

The image below shows the original 480 compared to the new asymmetrical 480 with a smoother closing ramp. The HD XR 750 cam is thrown in for comparison.

It has .435” lobe lift. Some are afraid to use it because it puts so much stress on the valve train. Flank acceleration is very high and cannot be avoided without stretching the duration too far. You can’t increase the spring pressure too much or you will only put more wear on the valve train. But you can reduce the closing jerk so the valves won’t crash down too hard and cause destructive valve bounce. This will enable it to revv higher than the original 480 while still avoiding valve clash. The idea is too build a high output 9000 RPM 750 short stroke land speed racer.

I don’t know if there is anything you can do to get such a cam to revv so high but we will try. Other cam designs have incorporated the smooth ramps and will revv to 9000 but they don’t have as much lift or acceleration as the 480. Too much spring pressure would again add strain to the mix. A tapered spring with about 150 lbs seat pressure will be used. But heavier large diameter valves with add to the problem. Heavy stock Norton lifters are out of the question. Lightweight BSA lifters will be used because this is what the cam was originally designed for (and Triumph lifters) and the lighter weight will help with valve control.

Its an asymmetrical profile with a closing ramp that is longer than the opening ramp.

The numbers are being sent off to the cam grinder and the new cam will have to prove itself on the dyno.

The image below shows the original 480 compared to the new asymmetrical 480 with a smoother closing ramp. The HD XR 750 cam is thrown in for comparison.

Last edited: