- Joined

- Feb 21, 2019

- Messages

- 1,067

can't verify if i have an original configuration.

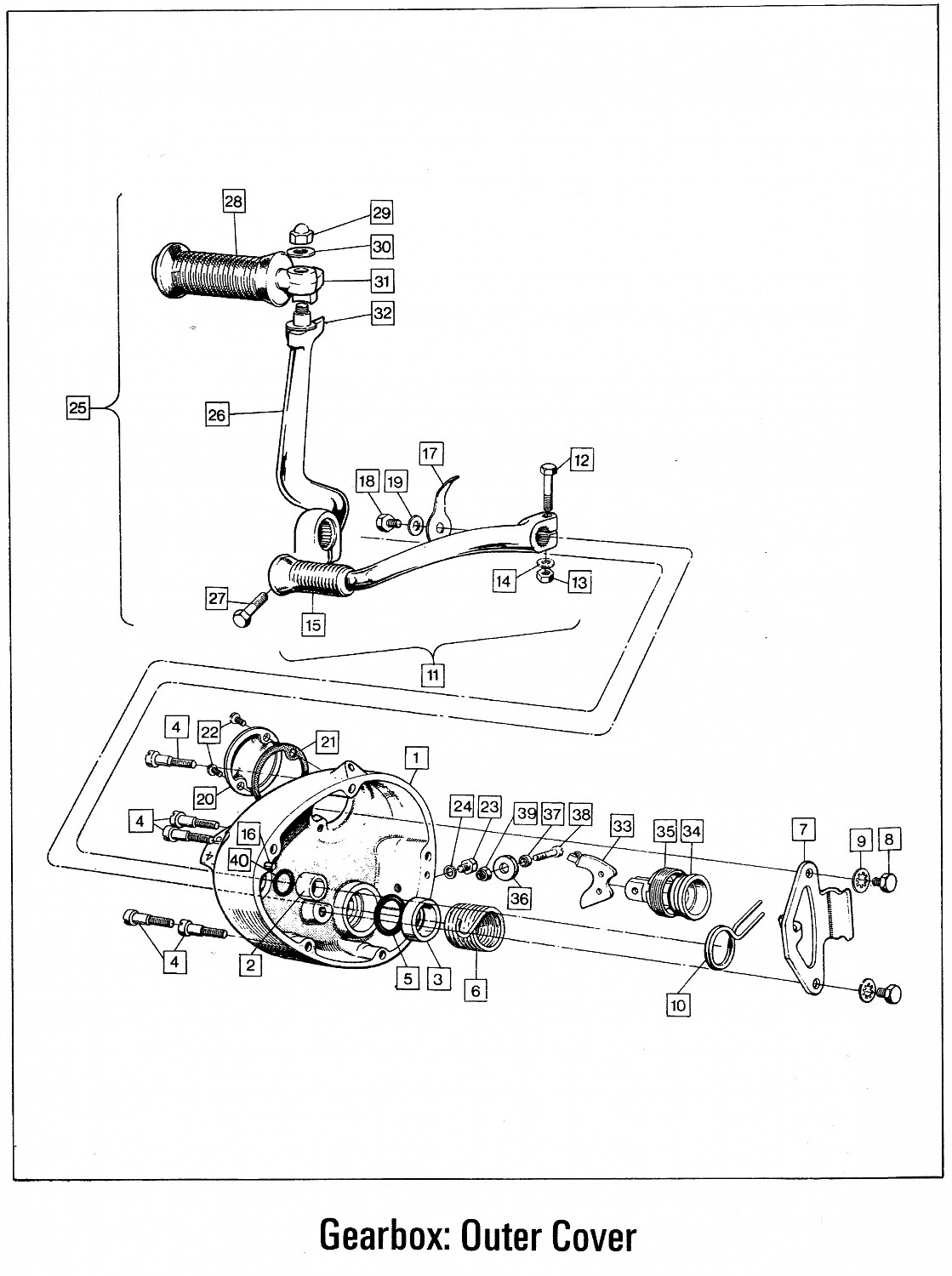

i'm taking my kick start lever apart, and notice my spring washer is broken, I also have two 3/8" washers, one above and one below the (broken) spring-washer, of which only one washer is shown on the parts drawing with no spring washer. the Mk3 shows a spring washer and one washer. is the spring-washer missing from the 73-74 parts diagram, and not sure why I have two washers. it should be configured as the 75 Mk3 - ???

i'm taking my kick start lever apart, and notice my spring washer is broken, I also have two 3/8" washers, one above and one below the (broken) spring-washer, of which only one washer is shown on the parts drawing with no spring washer. the Mk3 shows a spring washer and one washer. is the spring-washer missing from the 73-74 parts diagram, and not sure why I have two washers. it should be configured as the 75 Mk3 - ???

Last edited: