- Joined

- Apr 22, 2020

- Messages

- 3,423

It's a work in progress... not done yet.

Step 1: Get the AMC gearbox out of the mounting plates.

Really hoping I can do any modifications needed without taking the plates out of the frame. Could be a little too optimistic.

Step 1 is as far as I've gotten.

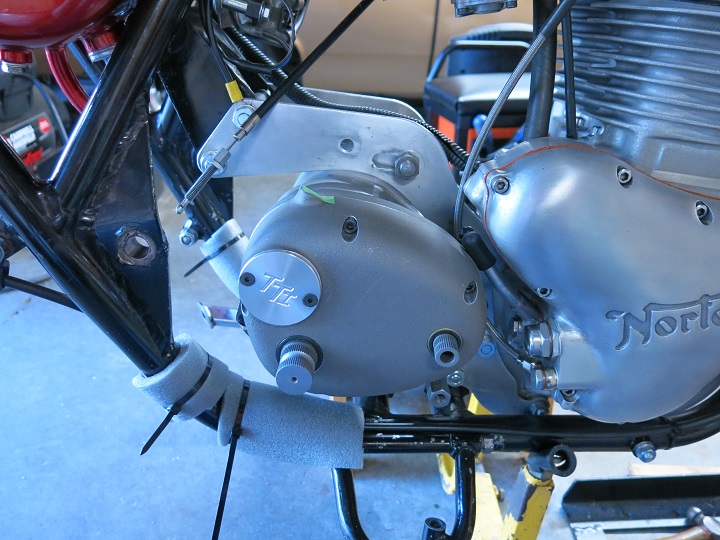

Hole where the TTi gearbox will go. More later

Step 1: Get the AMC gearbox out of the mounting plates.

Really hoping I can do any modifications needed without taking the plates out of the frame. Could be a little too optimistic.

Step 1 is as far as I've gotten.

Hole where the TTi gearbox will go. More later