Geez - sorry I ruffled feathers on this topic. I was trying to get an authoritative answer to the "standpipe" question where sump reed valves are concerned...and instead, I got remarks on the extremes. So, let me try again by putting the question differently: Has anyone measured the distance from the base (gasket surface) of these reed sump plugs to the top of the standpipe? It seems very likely that measurement would be optimal for proper function.

Join the Access Norton Community

- Thanks for visiting Access Norton

- 2 free views left

- Create a free account (more details)

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil valve solution to oil falling to crankcase

- Thread starter javifoto70

- Start date

- Status

- Not open for further replies.

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 3,711

See if I can get this in before LAB closes the thread.I prefer my solution, a ball valve with ignition defeat on feed line. Wet sump completely prevented. No risk of starting without oil feed to pump. Feked in UK sells such a valve with switch for about $80. I made my own for about $10 in hardware store parts and a micro switch.

I bought a Feked ball valve - $50 something US. It is huge. They show the measurements on the site, but I was not paying attention when I bought it. It's in a tool box drawer now. I use a smaller manual ball valve with no electrical cut out. Not recommended for the gen pop. If I blow my engine up, I won't be blaming it on the ball valve. It will be because I am a dumb ass and forgot to open it before starting the bike. I also have a reed valve, but at the rear of the timing cover. It is only for relieving crank case pressure.

The smaller valve that I use shown below has slightly larger 3/8" I.D. hose fittings than the Feked part. Absolutely not recommending this red handle no cut out switch ball valve solution.

- Joined

- Nov 26, 2009

- Messages

- 3,411

If your engine is completely wet sumped then there is plenty of oil in there to lube the con rod bearings - the bearings will dip into the oil every revolution until the oil pump takes over. Oil will also be splashed onto the camshaft the 1st revolution. It only takes a few squirts of sump oil into the oil tank for oil to enter the hose to the oil pump. Norton motors are blown up by shut off valves left closed. Not by wetsumping. I've let mine wet sump over 40 years - the only problem was me overfilling the oil tank once and then blowin out some oil. Adding a 1/16" cross section O ring next to the crank main seal keeps it from blowing out (see photo).

The standpipes can be different lengths. A case with an oil dam in it will need a shorter standpipe. Without the dam the stanpipe can be taller as long as it clears the flywheel.

The standpipes can be different lengths. A case with an oil dam in it will need a shorter standpipe. Without the dam the stanpipe can be taller as long as it clears the flywheel.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 6,023

I have not and would not bother since there are several crankcases involved (e.g., 750 before 72, 750 after 72, 850 before MK3, MK3). Optimal for the breather's actual job is anywhere above the running sump oil level at speed. The side effect of quickly removing excess oil in a web sump condition doesn't matter much because the oil pump will do its job and the breather only gets the excess out quicker - the less of that done the better because it does not go through the oil filter on those bikes with one.Geez - sorry I ruffled feathers on this topic. I was trying to get an authoritative answer to the "standpipe" question where sump reed valves are concerned...and instead, I got remarks on the extremes. So, let me try again by putting the question differently: Has anyone measured the distance from the base (gasket surface) of these reed sump plugs to the top of the standpipe? It seems very likely that measurement would be optimal for proper function.

Take that as authoritative or not as you please, but please don't crap on people trying to answer you.

Tornado

VIP MEMBER

- Joined

- Dec 5, 2017

- Messages

- 5,298

With a full wet sump there is no pressurized oil feeding crank crank bearings, just sitting in oil. Is that of concern? What about no feed to rockers until pump gets fed?If your engine is completely wet sumped then there is plenty of oil in there to lube the con rod bearings - the bearings will dip into the oil every revolution until the oil pump takes over. Oil will also be splashed onto the camshaft the 1st revolution. It only takes a few squirts of sump oil into the oil tank for oil to enter the hose to the oil pump. Norton motors are blown up by shut off valves left closed. Not by wetsumping. I've let mine wet sump over 40 years - the only problem was me overfilling the oil tank once and then blowin out some oil. Adding a 1/16" cross section O ring next to the crank main seal keeps it from blowing out (see photo).

The standpipes can be different lengths. A case with an oil dam in it will need a shorter standpipe. Without the dam the stanpipe can be taller as long as it clears the flywheel.

I had an issue with the case pressure blowing the crank seal in half from starting when wet sumped. Oil filled primary and started lubing rear tire heavily before I noticed. Could have been a major issue. This is what prompted my manual ball valve with defeat switch setup. No worries now.

Tornado

VIP MEMBER

- Joined

- Dec 5, 2017

- Messages

- 5,298

So due to asethetics, you choose to live dangerously ;-)See if I can get this in before LAB closes the thread.

I bought a Feked ball valve - $50 something US. It is huge. They show the measurements on the site, but I was not paying attention when I bought it. It's in a tool box drawer now. I use a smaller manual ball valve with no electrical cut out. Not recommended for the gen pop. If I blow my engine up, I won't be blaming it on the ball valve. It will be because I am a dumb ass and forgot to open it before starting the bike. I also have a reed valve, but at the rear of the timing cover. It is only for relieving crank case pressure.

The smaller valve that I use shown below has slightly larger 3/8" I.D. hose fittings than the Feked part. Absolutely not recommending this red handle no cut out switch ball valve solution.

You could fit a switch to the valve you have.

My setup uses a PEX type valve and it reasonable svelt:

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 6,023

Crank bearings, not really a problem as they are well oiled even without pressure in this case - for one thing, the crank is partly to completely full of oil and the force of it spinning will add oil to the shells.With a full wet sump there is no pressurized oil feeding crank crank bearings, just sitting in oil. Is that of concern? What about no feed to rockers until pump gets fed?

I had an issue with the case pressure blowing the crank seal in half from starting when wet sumped. Oil filled primary and started lubing rear tire heavily before I noticed. Could have been a major issue. This is what prompted my manual ball valve with defeat switch setup. No worries now.

Rocker spindles don't last long with no oil - that's my concern about check valves (un-primed pumps). I am MUCH more concerned about check valves where you have NO control over whether it opens or not.

As long as you never forget to open the shutoff valve, and as long as you don't start the bike immediately after opening it, you'll never be wet sump'ed and never have a problem. There is a really good chance that your microswitch will prevent that, but in my early years of repairing electromechanical machines, a large percentage of failures was microswitches. For more safety, I would route the shutoff well below the metal feed line to the engine so there is definitely at least some oil in the line after the shutoff.

When I bought my rider, it had a shutoff and a magnet with "oil" written on it. The previous owner says he never had a problem remembering to move the magnet to the side of the tank from the top when he opened the valve - that was his "fail safe". Apparently worked better for his brain than mine!

Greg - I swear it was never my intention to crap on people...especially if they are trying to help. I just want to understand. Maybe it's too many years of messing with Harleys, but I am concerned with oil drag (sumping) while the engine runs at high rpm. Forget reed valves for the moment, tell me if Commandos (in otherwise good condition) scavenge well enough, not to have that problem. (Wasn't it an oiling issue that was at the core of the issues with Combat engines?)

Last edited:

Thanks JS! Do 850s have an 'oil dam"? Which Commandos do not? Also, it'd be good to have your input on the question in post #269I have not and would not bother since there are several crankcases involved (e.g., 750 before 72, 750 after 72, 850 before MK3, MK3). Optimal for the breather's actual job is anywhere above the running sump oil level at speed. The side effect of quickly removing excess oil in a web sump condition doesn't matter much because the oil pump will do its job and the breather only gets the excess out quicker - the less of that done the better because it does not go through the oil filter on those bikes with one.

Take that as authoritative or not as you please, but please don't crap on people trying to answer you.

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 6,023

Those with the "1972" cases, including Combats, could have that problem - no others. Those cases do not have the big sump plug. It was not an oiling issue for Combats, it was a main bearing issue. At high enough sustained speed the oiling issue affected those with that case, not just Combats. If not racing, it is highly unlikely that there will ever be a real issue with the 1972 cases. Combats (and the rest) are reliable on the street as long as the correct main bearings are used.Greg - I swear it was never my intention to crap on people...especially if they are trying to help. I just want to understand. Maybe it's too many years of messing with Harleys, but I am concerned with oil drag (sumping) while the engine runs at high rpm. Forget reed valves for the moment, tell me if Commandos (in otherwise good condition) scavenge well enough, not to have that problem. (Wasn't it an oiling issue that was at the core of the issues with Combat engines?)

Search for "main bearings" here to read about it: https://www.gregmarsh.com/MC/Norton/SRList.aspx

Note: I have not tried to make a fine/detailed point here - there are other nuances to this discussion.

Last edited:

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,855

You have an 850 right? You have absolutely nothing to worry about in this regard.Greg - I swear it was never my intention to crap on people...especially if they are trying to help. I just want to understand. Maybe it's too many years of messing with Harleys, but I am concerned with oil drag (sumping) while the engine runs at high rpm. Forget reed valves for the moment, tell me if Commandos (in otherwise good condition) scavenge well enough, not to have that problem. (Wasn't it an oiling issue that was at the core of the issues with Combat engines?)

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 3,711

Not about aesthetics. That big valve won't fit easily where I want it to go. Putting off trying to install it until after I get a TTi box in the frame. TTi box won't show up till February or March 2024.So due to asethetics, you choose to live dangerously ;-)

You could fit a switch to the valve you have.

My setup uses a PEX type valve and it reasonable svelt:

I hang my key on the valve handle. That valve has been on the bike for 2+ years since I pulled the thing out of the corner of the garage where it sat for 27 years and I did what Jim mentioned filling the oil tank when the sump was completely full. What a mess. I noticed a 2.5 inch wide line of oil 10 feet long in my driveway when I got back from going around the block. I thought I had drained the oil before parking it for 27 years. Oil tank was basically empty, so I filled it. lol

I might be able to fit a switch to the smaller valve I have. Incentive is low though.

- Joined

- Nov 26, 2009

- Messages

- 3,411

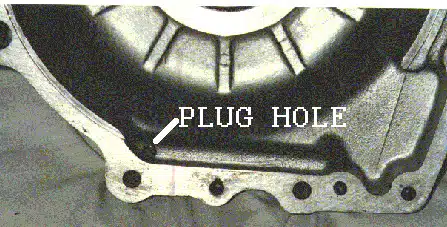

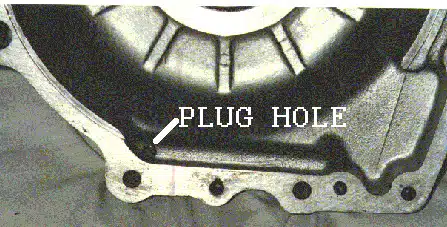

Here's the mods to make on the Combat case. Combats need this or the oil can pile up in the sump while running. Other 750s with the large sump plug don't have the dam so there is no problem. 850s with the dam work better if the dam is removed but that's not nearly as important as it is on a 72 Combat. Its easy to check for a dam by removing the large sump plug and sticking your finger in there.

Last edited:

My 1970 750 wet sumps very easily, three weeks without use and the oil tank is empty, and the sump is full.

I have fitted a JS sump plug reed valve (the only one that fits with a 1970 frame) and now I don't have to faff around draining the sump and putting oil back in the tank, with a Dunstall exhaust running below the drain plug its very difficult to keep the oil clean when draining. And the miscellaneous leaks like the rev-counter drive have all stopped leaking, so I'm delighted.

My new observation to add to the discussion is that I recently started my wet-sumped engine, and observed the oil pressure, which is taken from the base of the rocker feed. The engine started with an empty oil tank, the breather and oil pump will have started pushing oil up to the tank, but it took maybe 5~10 seconds before the oil pressure jumped from 0 to about 40psi. In that time I guess the bottom end was fine, with oil splashing everywhere, but the rocker feed would have been dry.

Is this as serious as it sounds?

I have fitted a JS sump plug reed valve (the only one that fits with a 1970 frame) and now I don't have to faff around draining the sump and putting oil back in the tank, with a Dunstall exhaust running below the drain plug its very difficult to keep the oil clean when draining. And the miscellaneous leaks like the rev-counter drive have all stopped leaking, so I'm delighted.

My new observation to add to the discussion is that I recently started my wet-sumped engine, and observed the oil pressure, which is taken from the base of the rocker feed. The engine started with an empty oil tank, the breather and oil pump will have started pushing oil up to the tank, but it took maybe 5~10 seconds before the oil pressure jumped from 0 to about 40psi. In that time I guess the bottom end was fine, with oil splashing everywhere, but the rocker feed would have been dry.

Is this as serious as it sounds?

- Joined

- May 7, 2005

- Messages

- 7,711

It does not sound serious, there will be residual oil.Is this as serious as it sounds?

Edfury828

VIP MEMBER

- Joined

- Jun 21, 2023

- Messages

- 155

I don't see any mention of using the kicker to move the oil before starting.

My new NYC Reed valve instructions (not installed yet) refer to kicking 10 times, or up to 10 times before starting... that seemed like a lot to me.

It would be nice to just start the engine and let the oil sort itself out if that's safe, or kick it over a few times to get things moving before starting.

I'm thinking that kicking it over some amount before starting would be good when wet sumped, but what would be a safe minimum amount of kicks?

Should I watch for how many kicks return the oil to a certain level in the tank?

I am also curious, did the JS instructions have a reccomended number of pre start kicks?

My new NYC Reed valve instructions (not installed yet) refer to kicking 10 times, or up to 10 times before starting... that seemed like a lot to me.

It would be nice to just start the engine and let the oil sort itself out if that's safe, or kick it over a few times to get things moving before starting.

I'm thinking that kicking it over some amount before starting would be good when wet sumped, but what would be a safe minimum amount of kicks?

Should I watch for how many kicks return the oil to a certain level in the tank?

I am also curious, did the JS instructions have a reccomended number of pre start kicks?

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 6,023

IMHO, zero pre kicks. If very wet sump'ed, it probably won't start for a few kicks as you'll have trouble making it spin fast enough. There is the chance of blowing the crank seal, but Nortons were started for a very long time before the sump reed valves came into use. With a sump reed valve, I simply start them.I'm thinking that kicking it over some amount before starting would be good when wet sumped, but what would be a safe minimum amount of kicks?

Edfury828

VIP MEMBER

- Joined

- Jun 21, 2023

- Messages

- 155

Thank you for your honest reply Marshg246. I'm sure opinions vary, and we may hear a few, but at least if I forget to kick it I won't have to worry!

I'm still trying to perfect my cold start choke technique, and I have the stock Prestolite 2 brush starter (with new cables) so my engine won't be turning over very quickly, or probably even starting right away!

I'm glad to hear also that MichaelD's oil leaks stopped with the Reed valve installation, yay!

I've been very busy since buying my new (to me) Norton, but hope to get it out on the road, weather permitting soon!

I'm still trying to perfect my cold start choke technique, and I have the stock Prestolite 2 brush starter (with new cables) so my engine won't be turning over very quickly, or probably even starting right away!

I'm glad to hear also that MichaelD's oil leaks stopped with the Reed valve installation, yay!

I've been very busy since buying my new (to me) Norton, but hope to get it out on the road, weather permitting soon!

The JS instructions didn't mention wet sumping, they were more about how to get the most effective power increase from the valve. I haven't noticed extra power, but it seems reasonable if the crankcases are at near vacuum, then the pumping effect of those two cylinders going up and down wouldn't be taking power.I don't see any mention of using the kicker to move the oil before starting.

My new NYC Reed valve instructions (not installed yet) refer to kicking 10 times, or up to 10 times before starting... that seemed like a lot to me.

It would be nice to just start the engine and let the oil sort itself out if that's safe, or kick it over a few times to get things moving before starting.

I'm thinking that kicking it over some amount before starting would be good when wet sumped, but what would be a safe minimum amount of kicks?

Should I watch for how many kicks return the oil to a certain level in the tank?

I am also curious, did the JS instructions have a reccomended number of pre start kicks?

Last week, without anyone suggesting it, I tried kicking the bike over 10 times before trying to start it. The bike had sat for three weeks and would definitely have wet-sumped. After those 10 kicks, the bike just didn't want to start, after a break it usually takes maybe 5 kicks to get it moving, but it took over 20 minutes to get it moving this time. I took out a plug and it didn't look flooded, so I just carried on kicking until it got going. Not going to try that again, my knee can't take the strain.

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 9,404