p400

VIP MEMBER

- Joined

- Jul 14, 2014

- Messages

- 1,296

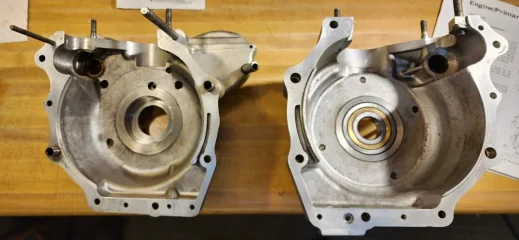

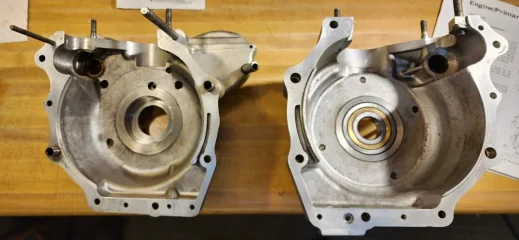

I am ready to install rods, but thought it would be best confirm if any "centering" of the crankshaft is required.

Nothing seems to be mentioned in workshop manual.

I am used to keeping some honed out inner races that slip on the crank, bolt up, and make plans from there.

I dont find that part of Norton work on crank.

Shims better on outer race?

Shims better on crank behind inner race?

End play not an issue with MK3?

Nothing seems to be mentioned in workshop manual.

I am used to keeping some honed out inner races that slip on the crank, bolt up, and make plans from there.

I dont find that part of Norton work on crank.

Shims better on outer race?

Shims better on crank behind inner race?

End play not an issue with MK3?

Last edited: