Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 3,710

Total waste of money on a street bike, but I only have one left, and only a few years left, so what the heck, why not do something foolish.It seems that an extra few hp can be very costly to find, even more costly to keep!

Ive got standard lifters in an alloy barrel for the 920. A standard but nitrided nos stock cam is lifting them.

Cost was very low, but I wonder if the alloy tunnels will hold up. I guess you have that concern too.

I recall that G81 was investigating this, not sure if he came to a conclusion or just dropped the plan to build alloy cylinders and left that with Andy Molnar.

Glen

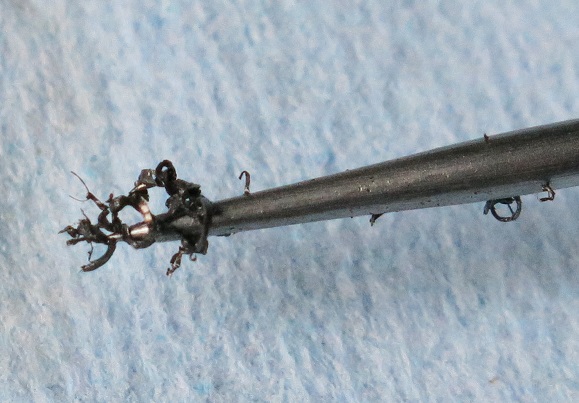

Yes, I wondered about the tappet bores in the alloy barrels, but they seem sturdy enough to outlast me with the stock tappets in them. That is not what is in it now though. Touched up by me JSM Triumph lifters and Triumph blocks are in it.

If I have bronze metallic in my oil when I drain it again, I'll ride till it starts making noise, then tear it down and decommission the remaining JSM parts. Stock flat tappets will be used in the alloy barrels. Not sure about what cam I would use. I don't really need a hot rod cam anymore.