- Joined

- Oct 1, 2018

- Messages

- 63

Hi Everybody,

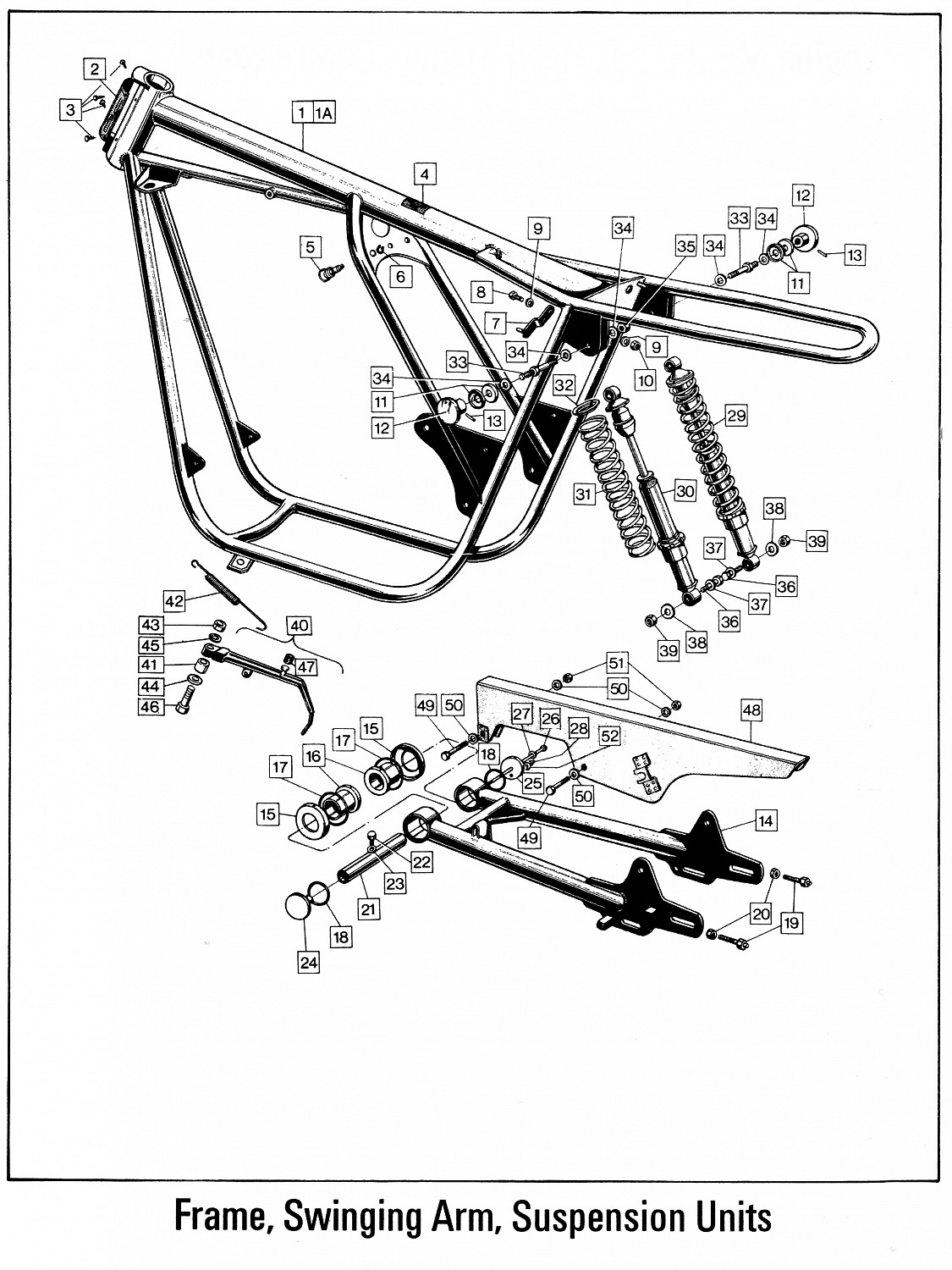

Steadfast Cycles has a welch cap for the swingarm that has a grease fitting threaded hole. Question: does it make sense to fit this and pump my old swingarm full of new grease? I don't have a problem with excessive play , but it probably has been 45 years since it had its grease put in!

Sincerely,

Kara

Steadfast Cycles has a welch cap for the swingarm that has a grease fitting threaded hole. Question: does it make sense to fit this and pump my old swingarm full of new grease? I don't have a problem with excessive play , but it probably has been 45 years since it had its grease put in!

Sincerely,

Kara