storm42

VIP MEMBER

- Joined

- Jul 20, 2011

- Messages

- 1,220

I am looking at building a 500cc single race bike and picked up an ES2 engine that has been played with.

The seller had run the engine in a parade at Cadwell park and was quite enthusiastic about how the motor felt, he said it was very smooth and seemed to go well, he said it was ready to race. He broke the bike up to fund a Manx, lucky chap.

I don't think he built the engine, I believe that it was built in Denmark and there is a video here of the Danish owner running the bike up when it was in one piece.

The engine turned over very smooth and there didn't seem to be anything knocking when rocking it back and forth, but, there was silicon hanging out of just about every joint and I don't like that stuff, and I was curious what was in the thing so I decided to strip it.

This is turning out to be one of those times when I am glad I am a nosey sod.

The first problem was the cam timing, I checked it so I could rebuild the motor with the same timing as when it was running, oh dear.

Inlet opens 70 deg BTDC and closes 87deg ABDC thats 337 deg duration with 98.5 deg center.

Exhaust opens 87 deg ATDC and closes 61 deg ATDC so 328 deg duration and 103 deg center.

Checked with .004" clearance. seems odd to me. Also, it looks like the cam followers have been touching the inside of the cam gears, here is a pic to show that and the difference between what is in there and standard cams.

The next problem was the piston, there are signs of the valves hitting it.

I initially thought valve float, but amongst the paperwork that came with the engine were a few emails between the Danish guy and Mike Pemberton, they were using google translate and it looked like the builder was struggling with setting the cam timing so maybe the problem has gone away considering the guy I bought it off had been running it. I will be checking clearances though.

I then noticed that all the ring gaps were lined up, also not good, I then realised the piston was fitted back to front, the pic below show contact where the inlet valve has been hitting the edge of the exhaust valve pocket.

There is some kind of coating on the piston so I am not sure if the colours visible in the next pic are to do with that or heat.

Incidentally, I want to be out on track with this engine on the 18th March at the test day at Mallory, as I was taking this apart, I didn't have anything else other that the gearbox(that will be coming apart next)

Fortunately, the rolling chassis I have bought landed from Germany last night so that may speed the build up, I am hoping this will turn out to be quite special but so far, as usual things are conspiring against me.

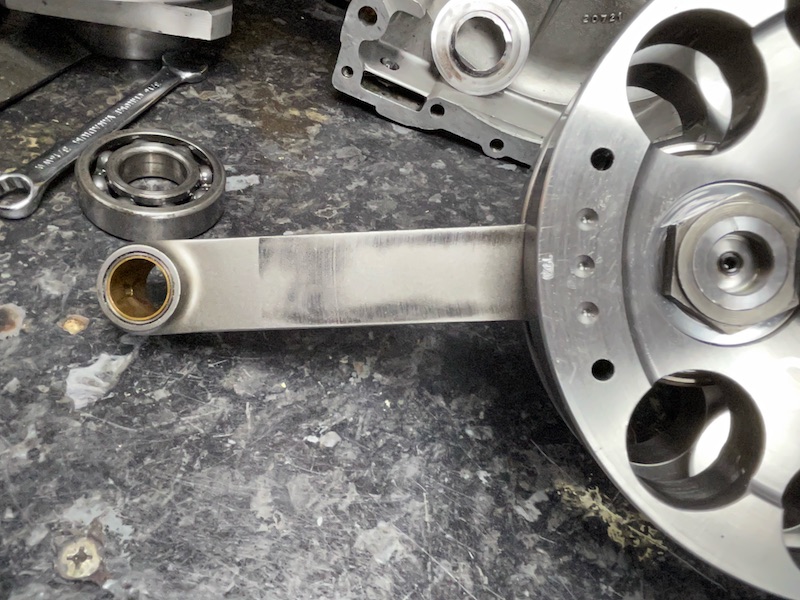

Onwards, and time to split the cases, the crank and rod look special.

But then I notice the bearing in the rod is not centred, this means the rod can touch the crank cheek on the timing side, this looks really bad in the pic but it is more of a polish that proper damage.

Also there was a shim in the drive side which is the same size as the bearing ID/OD, you can see it in the background, obviously that cannot work and the result is pictured below.

Oh well, back in the garage to try and work out a plan of action, it wouldn't be fun if every thing was OK, would it?

The seller had run the engine in a parade at Cadwell park and was quite enthusiastic about how the motor felt, he said it was very smooth and seemed to go well, he said it was ready to race. He broke the bike up to fund a Manx, lucky chap.

I don't think he built the engine, I believe that it was built in Denmark and there is a video here of the Danish owner running the bike up when it was in one piece.

The engine turned over very smooth and there didn't seem to be anything knocking when rocking it back and forth, but, there was silicon hanging out of just about every joint and I don't like that stuff, and I was curious what was in the thing so I decided to strip it.

This is turning out to be one of those times when I am glad I am a nosey sod.

The first problem was the cam timing, I checked it so I could rebuild the motor with the same timing as when it was running, oh dear.

Inlet opens 70 deg BTDC and closes 87deg ABDC thats 337 deg duration with 98.5 deg center.

Exhaust opens 87 deg ATDC and closes 61 deg ATDC so 328 deg duration and 103 deg center.

Checked with .004" clearance. seems odd to me. Also, it looks like the cam followers have been touching the inside of the cam gears, here is a pic to show that and the difference between what is in there and standard cams.

The next problem was the piston, there are signs of the valves hitting it.

I initially thought valve float, but amongst the paperwork that came with the engine were a few emails between the Danish guy and Mike Pemberton, they were using google translate and it looked like the builder was struggling with setting the cam timing so maybe the problem has gone away considering the guy I bought it off had been running it. I will be checking clearances though.

I then noticed that all the ring gaps were lined up, also not good, I then realised the piston was fitted back to front, the pic below show contact where the inlet valve has been hitting the edge of the exhaust valve pocket.

There is some kind of coating on the piston so I am not sure if the colours visible in the next pic are to do with that or heat.

Incidentally, I want to be out on track with this engine on the 18th March at the test day at Mallory, as I was taking this apart, I didn't have anything else other that the gearbox(that will be coming apart next)

Fortunately, the rolling chassis I have bought landed from Germany last night so that may speed the build up, I am hoping this will turn out to be quite special but so far, as usual things are conspiring against me.

Onwards, and time to split the cases, the crank and rod look special.

But then I notice the bearing in the rod is not centred, this means the rod can touch the crank cheek on the timing side, this looks really bad in the pic but it is more of a polish that proper damage.

Also there was a shim in the drive side which is the same size as the bearing ID/OD, you can see it in the background, obviously that cannot work and the result is pictured below.

Oh well, back in the garage to try and work out a plan of action, it wouldn't be fun if every thing was OK, would it?