jms

VIP MEMBER

- Joined

- Jul 26, 2005

- Messages

- 183

The Atlas that I recently purchased came with two new main bearings in anticipation of a rebuild.

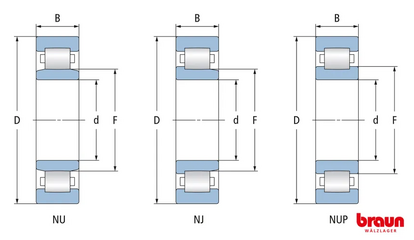

1. One is a roller bearing branded as Consolidated but is actually a Steyr NU-306 E on the outer race and NU-306 E

2. The other is a Fafnir 306W ball bearing

Here's the question. Once I get around to the rebuild do I use these bearings?

Thanks

1. One is a roller bearing branded as Consolidated but is actually a Steyr NU-306 E on the outer race and NU-306 E

2. The other is a Fafnir 306W ball bearing

Here's the question. Once I get around to the rebuild do I use these bearings?

Thanks