Swingarm bushing reaming

- Thread starter jamesp

- Start date

- Status

- Not open for further replies.

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

I agree, just not able to find a shop that will do it here on the California Central Coast. I’m ok with shipping if someone could suggest where to send it.There are close tolerances involved to line up the swing arm to the cradle so it pivots as it should on the pin. My opinion is it's a job for a machinist who has the right tools.

Last edited:

- Joined

- Dec 28, 2008

- Messages

- 2,035

Does the pivot shaft fit the bushings snugly when the bushings are not in the cradle?

Do the bushings have an OD that is within .0010/.0015 of each other?

Measuring the ID of the tube the bushings fit into, what is the potential "pressed fit"?

Is the tube the bushings need to be fit into clean, smooth and free of indentations?

Side note: The bushings are not any more consistent in OD than the tube is consistent in ID.

Keep in mind that with the use of pivot shaft clamps the associated clearances could be real close to a hand fit.

These bushings aren't particularly expensive; I'd be inclined to purchase another set from another vendor before seeking the services of a machinist first; worst case you will have a set you can "work" any way that feels best. Considering the number of tolerances involved between the articulating swingarm and the rear wheel alignment to the centerline of the frame you have tons of "wiggle room" to come out with a tight, well aligned, smoothly articulating rear suspension. Do give the pivot shaft clamps some consideration, if you are not already planning them; you are at a point where installing them would be as easy as it gets.

Best.

Do the bushings have an OD that is within .0010/.0015 of each other?

Measuring the ID of the tube the bushings fit into, what is the potential "pressed fit"?

Is the tube the bushings need to be fit into clean, smooth and free of indentations?

Side note: The bushings are not any more consistent in OD than the tube is consistent in ID.

Keep in mind that with the use of pivot shaft clamps the associated clearances could be real close to a hand fit.

These bushings aren't particularly expensive; I'd be inclined to purchase another set from another vendor before seeking the services of a machinist first; worst case you will have a set you can "work" any way that feels best. Considering the number of tolerances involved between the articulating swingarm and the rear wheel alignment to the centerline of the frame you have tons of "wiggle room" to come out with a tight, well aligned, smoothly articulating rear suspension. Do give the pivot shaft clamps some consideration, if you are not already planning them; you are at a point where installing them would be as easy as it gets.

Best.

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

Thanks for responding. Not sure what you mean by pivot shaft clamps. The bushings come from Andover Norton so I think they should be good. They were a good fit to the shaft and pressed into the swing arm very smoothly. I have read other posts in this forum that reaming them is common. The cradle is new, the shaft fits well there, and the swing arm fits perfect to the cradle. The bushes just need a little opening up. I seem to be missing something in what you are trying to say. This is my first attempt at ground up restoration. Thanks.Does the pivot shaft fit the bushings snugly when the bushings are not in the cradle?

Do the bushings have an OD that is within .0010/.0015 of each other?

Measuring the ID of the tube the bushings fit into, what is the potential "pressed fit"?

Is the tube the bushings need to be fit into clean, smooth and free of indentations?

Side note: The bushings are not any more consistent in OD than the tube is consistent in ID.

Keep in mind that with the use of pivot shaft clamps the associated clearances could be real close to a hand fit.

These bushings aren't particularly expensive; I'd be inclined to purchase another set from another vendor before seeking the services of a machinist first; worst case you will have a set you can "work" any way that feels best. Considering the number of tolerances involved between the articulating swingarm and the rear wheel alignment to the centerline of the frame you have tons of "wiggle room" to come out with a tight, well aligned, smoothly articulating rear suspension. Do give the pivot shaft clamps some consideration, if you are not already planning them; you are at a point where installing them would be as easy as it gets.

Best.

- Joined

- May 7, 2005

- Messages

- 7,317

And don't use sandpaper or emery cloth as the pores will retain the grit and then wear the shaft out.I believe the bushings absorb oil so if the are machined make sure the cutter is very sharp as not to clog the pores.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,221

This is very importantThis has been discussed in the past, I believe the bushings absorb oil so if the are machined make sure the cutter is very sharp as not to clog the pores.

Search "swing arm bushing"

And as komando says no sandpaper etc

- Joined

- Dec 28, 2008

- Messages

- 2,035

The cradle is new, the shaft fits well there, and the swing arm fits perfect to the cradle. The bushes just need a little opening up. I seem to be missing something in what you are trying to say

New swingarms, typically, have a somewhat rough ID (where the bushings are installed), they also may have been treated to over spray or been painted; either one of these conditions can cause the bushing install to require more additional force the closure of the bushings' ID sufficient to require being reamed.

If the swingarm bores are clean and paint free and the unmounted bushings present a good fit to the pivot shaft, then clearly the bushings are being constricted when installed, which, in turn, causes the pivot shaft very difficult or no fitment in which case sending the pieces out to be reamed looks like the only avenue.

However.

As mentioned by other posters, do not use abrasives (paper or paste based) on the bushing ID surfaces as such will seal the "pores" meant to retain the gear oil lubricant. This, however, does not preclude you from reducing the bushings OD in any manner until you achieve a solid fit of the bushings in the swingarm and a snug fit of the shaft through the bushings; a hard rubber or hide hammer gently applied should be all that it takes t drive the shaft through the bushings.

Once you have achieved the proper fitment wash the bushings in something like Simple Green, then dish detergent. When they are completely dry and cooled then soak them in gear oil overnight, assemble, set the centering bolt, fit the clamps, which you had previously drilled for; I believe these are the best:

Swingarm Spindle Kit

Over the years of riding our silky smooth Commandos the torsional loads transmitted to the Isolastic-mounted engine cradle from the swingarm creates a worn sloppy spindle bore, resulting in vague, imprecise handing. Infamous Berliner staffer Heinz Kegler came up with a very simple yet elegant...

but you have a good choices, just not as purpose made or well supported. Disclaimer: I have no financial relationship with NYCN or its owner, just like their offerings. I have identical respect for cNw who also gets my business for custom parts/services; hell, could go on for pages about the hard working businesses that support the Norton addiction...

PM me if I can turn up the illumination, I am not in the Norton business, but 'am happy to help as I have made, what I think, are most of the mistakes and been fortunate to not have to repeat them. The one that follows me, like a bad day, that I need to make a poster for, is the rocker spindle oil hole orientation....

Best.

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

Thank you for clarifying, I appreciate it. The bushings are already in the bores and I don’t have good enough tools to be removing and reinstalling as many times as it would take until I can get a proper OD. I have a new cradle and Mark III conversion kit that keeps the oiled wick at the end of the pivot shaft which could help with oiling on a slightly machined bushing. My problem at this time seems to be finding a machine shop that would do the work. i sincerely appreciate your responses and trying to help out.New swingarms, typically, have a somewhat rough ID (where the bushings are installed), they also may have been treated to over spray or been painted; either one of these conditions can cause the bushing install to require more additional force the closure of the bushings' ID sufficient to require being reamed.

If the swingarm bores are clean and paint free and the unmounted bushings present a good fit to the pivot shaft, then clearly the bushings are being constricted when installed, which, in turn, causes the pivot shaft very difficult or no fitment in which case sending the pieces out to be reamed looks like the only avenue.

However.

As mentioned by other posters, do not use abrasives (paper or paste based) on the bushing ID surfaces as such will seal the "pores" meant to retain the gear oil lubricant. This, however, does not preclude you from reducing the bushings OD in any manner until you achieve a solid fit of the bushings in the swingarm and a snug fit of the shaft through the bushings; a hard rubber or hide hammer gently applied should be all that it takes t drive the shaft through the bushings.

Once you have achieved the proper fitment wash the bushings in something like Simple Green, then dish detergent. When they are completely dry and cooled then soak them in gear oil overnight, assemble, set the centering bolt, fit the clamps, which you had previously drilled for; I believe these are the best:

Swingarm Spindle Kit

Over the years of riding our silky smooth Commandos the torsional loads transmitted to the Isolastic-mounted engine cradle from the swingarm creates a worn sloppy spindle bore, resulting in vague, imprecise handing. Infamous Berliner staffer Heinz Kegler came up with a very simple yet elegant...nycnorton.com

but you have a good choices, just not as purpose made or well supported. Disclaimer: I have no financial relationship with NYCN or its owner, just like their offerings. I have identical respect for cNw who also gets my business for custom parts/services; hell, could go on for pages about the hard working businesses that support the Norton addiction...

PM me if I can turn up the illumination, I am not in the Norton business, but 'am happy to help as I have made, what I think, are most of the mistakes and been fortunate to not have to repeat them. The one that follows me, like a bad day, that I need to make a poster for, is the rocker spindle oil hole orientation....

Best.

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

Thank you.This is very important

And as komando says no sandpaper etc

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

Ok, thank you.This is very important

And as komando says no sandpaper etc

- Joined

- Dec 30, 2003

- Messages

- 3,689

You could try Phil Radford in Los Osos. He is retired but may still work on Commandos. He formerly sold Norton parts, but no more as owner of Fair Spares America. 805 534-9248.I agree, just not able to find a shop that will do it here on the California Central Coast. I’m ok with shipping if someone could suggest where to send it.

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

jamesp

VIP MEMBER

- Joined

- Aug 17, 2011

- Messages

- 484

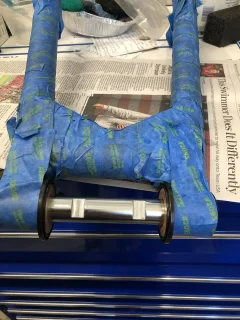

Thanks. I was glad to get it done, it was the last thing I needed to do to have the cradle ready for when the motor is done.Good on Ya...Looks nice with that new spindle and all.

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 1,623

- Replies

- 83

- Views

- 9,522