That is all and dandy but the stock AN stud does not have that diameter to thread engagement ratio.

The studs I made are machined to suit each head thread and the head thread (Besides dropping around $300++ on studs and inserts in a courser pitch) was my main concern.

I was in no doubt the brand new AN studs would have pulled out of this brand new cylinder head maybe at first assembly.

If you have made new studs that engage as per the stock stud depth (not use the thread available) and you use a torque wrench on a different TPI be careful is all I will say.

If these were to pull I would have no choice but go to a 16 or so TPI full depth so would make new studs to suit that.

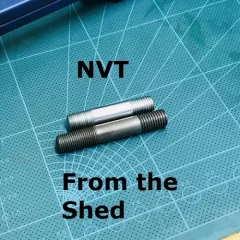

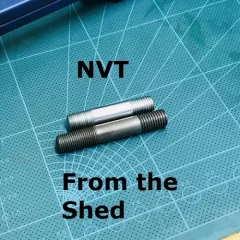

It is plain to see the depth difference here.

These have not moved to date, the four long cylinder cap screws (850) cold settled after eleven days. (before the cylinder head was installed)

I look forward to your thoughts when you are doing the last 30 ft/lb torque wrench pull on those three fasteners.

Maybe the hardened washers actually increase the applied torque because a lot of the friction (galling) has been removed from the fastener in direct contact with the cylinder.

There might be a good reason many just crank them as much as they dare with a ring spanner. (Seat each fastener then give them an equal amount of degree rotation )