Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

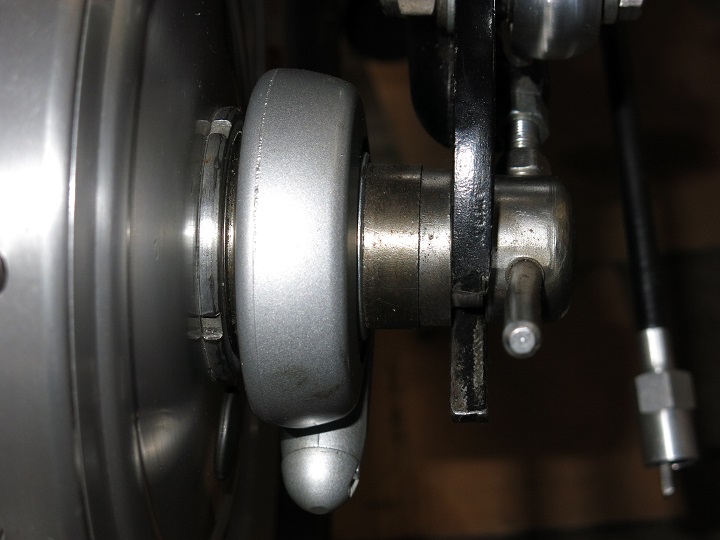

could someone please measure the distance from the outside of the speedo drive and the flange on the swing arm where the axle fits through. Thanks.

Mine is probably incorrect. The spacers and other pieces on my axle may be different since it is a '67 P11, and was not together when I picked it up in boxes. I came up with spacing that works, but it took a few tries. Anywho it's 1.75" on my P11 and made up of spacers, washers, and the speedo.

(Made a big mistake on where the measurement was taken from and here is the Edit

Ron L should have an accurate measurement if mine does not make sense on your P11A.

The spacing from the outside face of the speedo drive and the speedo internals is the one you have to get right or you or your customer might lock up the rear wheel when least expected.

Last edited: