- Joined

- Oct 28, 2014

- Messages

- 1,866

I have to go into the wheel and replace bearings and I hope that's all. Where can I get a diagram of the hub?

I am guessing that the tapered rollers are not adjusted and the wheel is flopping. My concern is when dealing with this wheel it could become a long project. That means the bike is immobile and takes up the floor space or the lift table until it's done which will be an open ended project. I would really like to substitute another Norton wheel.

I have to go into the wheel and replace bearings and I hope that's all. Where can I get a diagram of the hub?

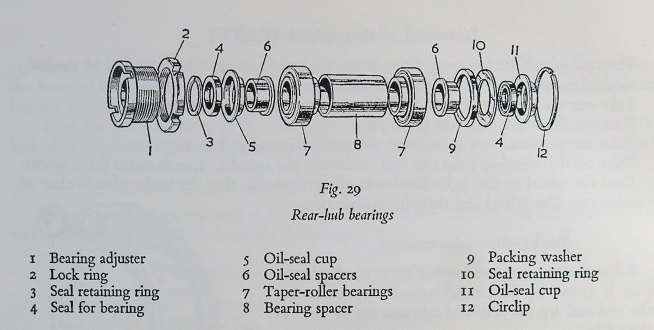

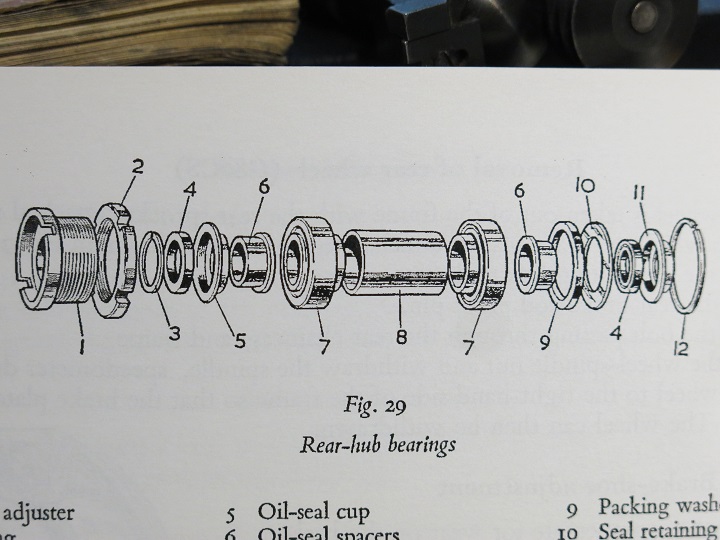

That looks way more complicated than necessary..This might help.

Hope you have the hub assembled in original condition with the speedo properly shimmed before taking it apart. If not shimmed correctly winding the speedo cable up on the rear axle can be exciting. Ask me how I know. Well, don't but you get the idea.

The OEM hub bearings are unique if it is the same hub I have on a '67 P11 not A. I got them from AMC Classic Spares. There may be other sources.

Norton Matchless Division design?That looks way more complicated than necessary..

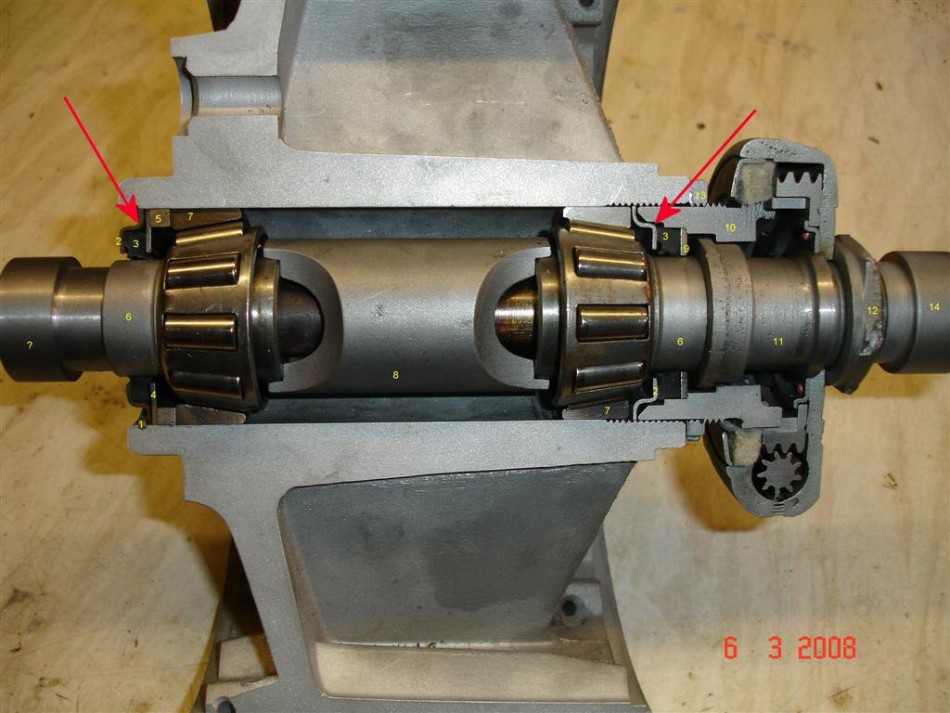

Don't think about it. The P11/G80CS rear wheel is superior, because of very strong taper roller bearings, which should last a life long, a one-piece axle of sufficient diameter, and the straight-pull spokes.I am guessing that the tapered rollers are not adjusted and the wheel is flopping. <...> I would really like to substitute another Norton wheel.

From the 1963 AJS service manual:P11's that were raced off road got some grit past the seals and in the rear hub bearings. If the bike was primarily used on the road in fair weather like a clean garaged P11A may have been, the bearings are probably in the OK range for a 56 year old bike. You have to get them out of the hub to find out.

Norton Matchless Division design?

Probably could be improved upon by a competent machinist.

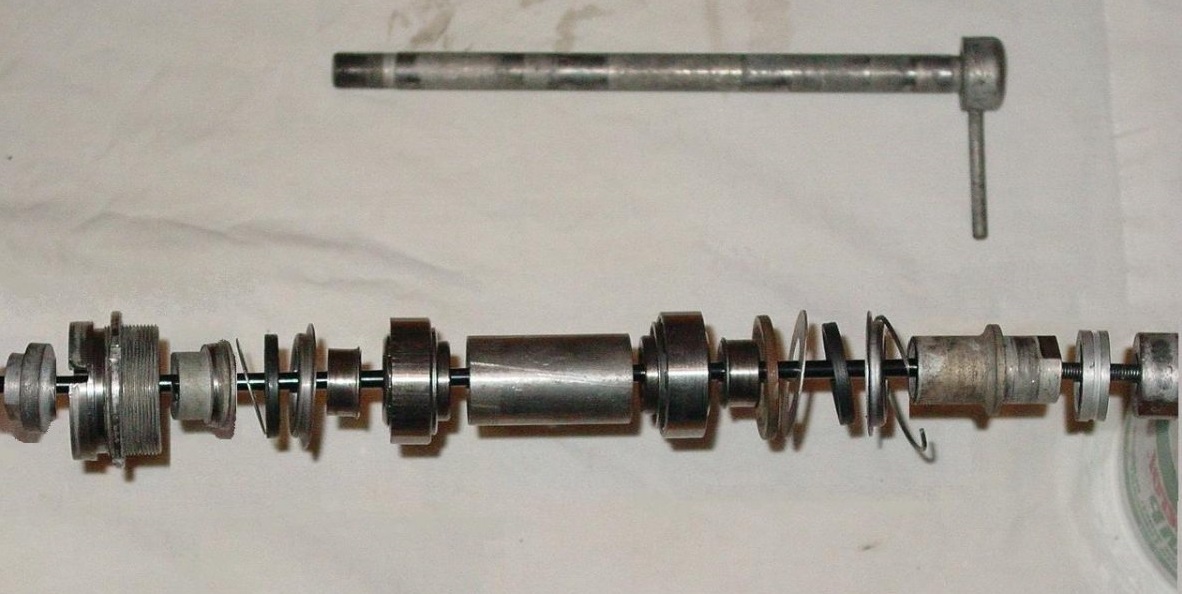

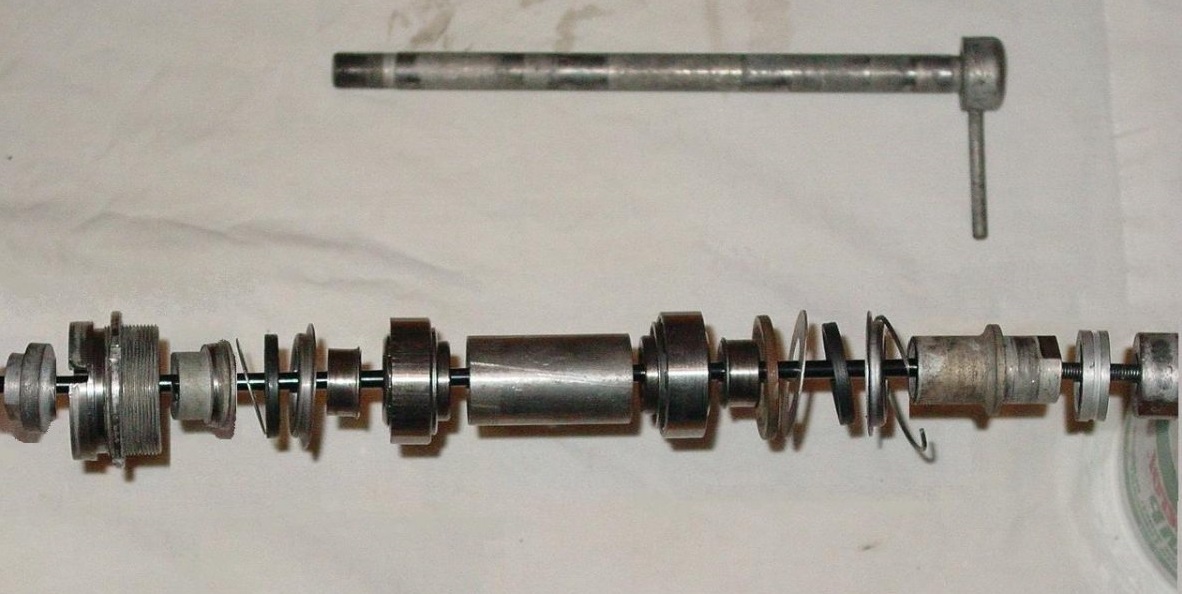

All that stuff on the skinny rod goes on that axle shown above it.

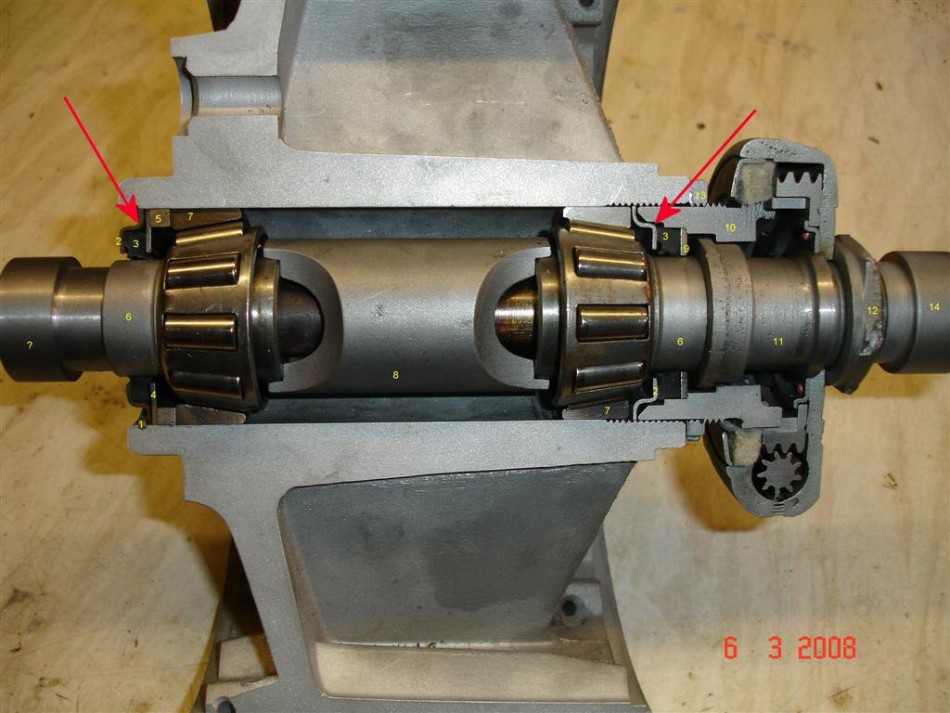

Below is a view I found of the bearings in the hub with axle inserted.

So how do you adjust the inner race to just the right amount of pressure?...just touching but no pressure and no slop? And when the axle is tightened it will reduce the nil clearance.

What is #4? Do you have a page that says what each piece is?