You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metalastic Swingarm Bushes

- Thread starter jms

- Start date

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,675

If I understand your question clearly...are you seeking guidance as to the proper technique to insert new bushes into your swing arm?

Some photos of present condition/status would help too.

Some photos of present condition/status would help too.

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,675

Assuming you meant bushings and not bearings?

So much of the process is good prep.

I can only give you my feedback on my own installation on a Commando.

I clear all paint from the inside of the bushing "ports" making them as smooth as possible. A very light wipe of lubricant on the interior of the receiving wall and the outside walls the bushes.

The outside walls of the bushings can be smoothed out with some steel wool or 800 + grit sandpaper, being careful to remove as little material as possible for a proper fit.

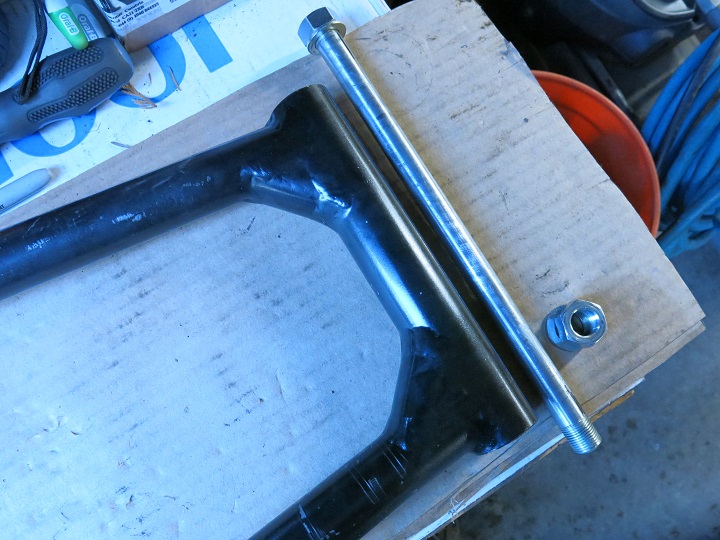

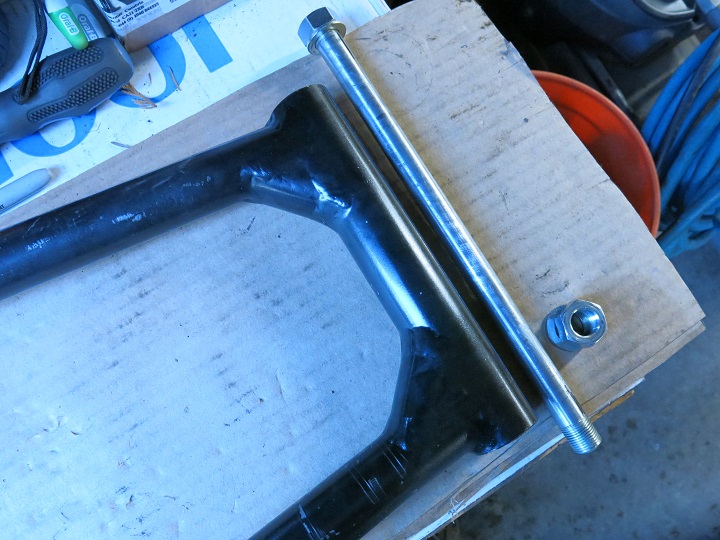

I disassembled a gear puller, removed the claw arms and ran the pulling bolt thru center of the puller T-arm, through the swing arm and bushing. I I used two heavy washers on the opposing (interior) side and then screwed a nut on the end of the pulling bolt. Get the bushing settled into the start point on the receiving "port" of the swing arm then snug down the puller bolt. Begin to evenly pull the bushing into place while turning down the main puller bolt with a wrench.

Just keep screwing the bolt tighter, not too much resistance but not too easy either, no binding allowed. Keep pulling the bushing into final seating position.

Some say you can tap them into place with a mallet or hammer, I do not use to this method.

There are others in here who can explain bushing installation more clearly than I but maybe this will get you started.

Hope this offers some insight.

So much of the process is good prep.

I can only give you my feedback on my own installation on a Commando.

I clear all paint from the inside of the bushing "ports" making them as smooth as possible. A very light wipe of lubricant on the interior of the receiving wall and the outside walls the bushes.

The outside walls of the bushings can be smoothed out with some steel wool or 800 + grit sandpaper, being careful to remove as little material as possible for a proper fit.

I disassembled a gear puller, removed the claw arms and ran the pulling bolt thru center of the puller T-arm, through the swing arm and bushing. I I used two heavy washers on the opposing (interior) side and then screwed a nut on the end of the pulling bolt. Get the bushing settled into the start point on the receiving "port" of the swing arm then snug down the puller bolt. Begin to evenly pull the bushing into place while turning down the main puller bolt with a wrench.

Just keep screwing the bolt tighter, not too much resistance but not too easy either, no binding allowed. Keep pulling the bushing into final seating position.

Some say you can tap them into place with a mallet or hammer, I do not use to this method.

There are others in here who can explain bushing installation more clearly than I but maybe this will get you started.

Hope this offers some insight.

Last edited:

Ron L

VIP MEMBER

- Joined

- Feb 27, 2004

- Messages

- 3,204

For the 'metalastic' rubber bushes in an Atlas (and P11) I have used a hydraulic shop press and a seal and bearing driver of a diameter to fit inside the arm and still contact the outer steel of the rubber bush. The inside of the swingarm should be scrupulously clean and free of any burrs from removing the old bush. I usually sand the outer surface of the bushing to remove any oxidation (rust) or paint. A shot of press-fit lube (I use PFL-200 from Goodson) makes the job a little easier.

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,675

Hello Ron L,

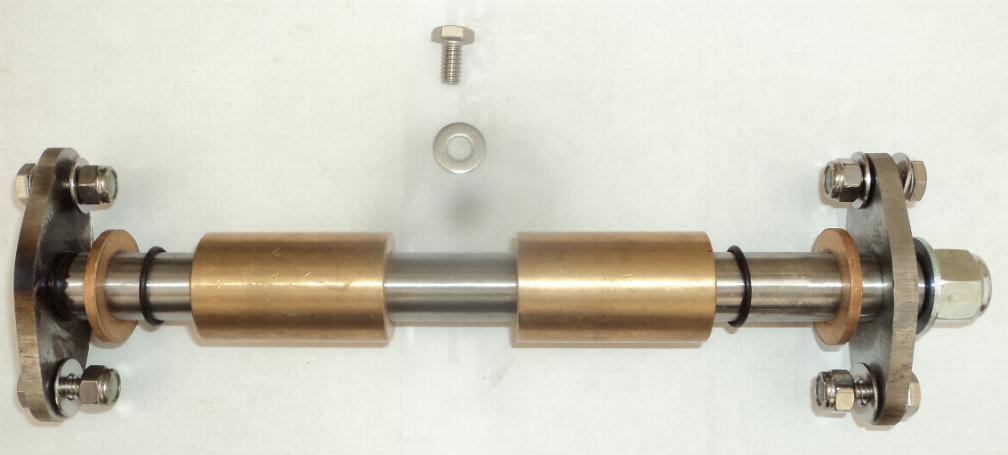

The last 3 photos I lifted from the "Bushing" site where I purchased them.

I actually managed to install the other components properly aka in order during the early stages of restoration on my bike.

I went with those specific bushings as they are impregnated with graphite and eliminate all the "oil to the bushing" maintenance (and drama) often associated with keeping the swingarm swinging.

No more swing arm lube dribbling around the tire and frame and floor.

The last 3 photos I lifted from the "Bushing" site where I purchased them.

I actually managed to install the other components properly aka in order during the early stages of restoration on my bike.

I went with those specific bushings as they are impregnated with graphite and eliminate all the "oil to the bushing" maintenance (and drama) often associated with keeping the swingarm swinging.

No more swing arm lube dribbling around the tire and frame and floor.

texasSlick

VIP MEMBER

- Joined

- Jan 2, 2013

- Messages

- 4,167

Don't even think about installing the Clayflex bushings without a hydraulic press!

But you probably know that, because you needed one to get them out.

Slick

But you probably know that, because you needed one to get them out.

Slick

drp

VIP MEMBER

- Joined

- Feb 11, 2011

- Messages

- 209

I successfully replaced the metalalastic bushing on my Atlas because I went the powder coat route too & it wasn't easy. I used a worn out 10 ton press at work and barely got them in. I made special pressing tools and had another person provide an extra set of hands. The pressing tools are the key.

So much force is required that bending the swingarm or cocking the bushings unless properly fixtured is a distinct possibility. I really doubt that pressing it in with a bolt or all thread will work, I think the threads will strip first.

I would polish the bushing OD and the swing arm bore ID, put the Busings in the freezer or in dry ice, coat the swing arm bore with a lubricant and then press them in quickly. You might consider putting a taper or lead on the end of the bushing to help with the initial alignment.

If I had to do it again I wouldn't. I'd powder coat the frame but spray the swing arm and if I had to replace the metalastic bushings I'd put them in before refinishing the swing arm and then paint the swing arm. This would allow freezing the bushing and using heat on the swing arm.

My advice is to "over fixture" the swing arm so it is rigidly perpendicular to the press ram and press them in from the "outside" pushing one in, flipping the swing arm over and pressing the other side in.

So much force is required that bending the swingarm or cocking the bushings unless properly fixtured is a distinct possibility. I really doubt that pressing it in with a bolt or all thread will work, I think the threads will strip first.

I would polish the bushing OD and the swing arm bore ID, put the Busings in the freezer or in dry ice, coat the swing arm bore with a lubricant and then press them in quickly. You might consider putting a taper or lead on the end of the bushing to help with the initial alignment.

If I had to do it again I wouldn't. I'd powder coat the frame but spray the swing arm and if I had to replace the metalastic bushings I'd put them in before refinishing the swing arm and then paint the swing arm. This would allow freezing the bushing and using heat on the swing arm.

My advice is to "over fixture" the swing arm so it is rigidly perpendicular to the press ram and press them in from the "outside" pushing one in, flipping the swing arm over and pressing the other side in.

jms

VIP MEMBER

- Joined

- Jul 26, 2005

- Messages

- 183

Thanks DRP. Will let you know how it works outI successfully replaced the metalalastic bushing on my Atlas because I went the powder coat route too & it wasn't easy. I used a worn out 10 ton press at work and barely got them in. I made special pressing tools and had another person provide an extra set of hands. The pressing tools are the key.

So much force is required that bending the swingarm or cocking the bushings unless properly fixtured is a distinct possibility. I really doubt that pressing it in with a bolt or all thread will work, I think the threads will strip first.

I would polish the bushing OD and the swing arm bore ID, put the Busings in the freezer or in dry ice, coat the swing arm bore with a lubricant and then press them in quickly. You might consider putting a taper or lead on the end of the bushing to help with the initial alignment.

If I had to do it again I wouldn't. I'd powder coat the frame but spray the swing arm and if I had to replace the metalastic bushings I'd put them in before refinishing the swing arm and then paint the swing arm. This would allow freezing the bushing and using heat on the swing arm.

My advice is to "over fixture" the swing arm so it is rigidly perpendicular to the press ram and press them in from the "outside" pushing one in, flipping the swing arm over and pressing the other side in.

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,675

Wow.

That sounds more involved than pressing sleeves into a cylinder block!

That entire configuration is a mid - 60's application, I have to believe there is a better alternative or other option on the market/available than having to involve such drastic methods, 10 ton hydraulic press, dry ice or liquid nitrogen?

Just to insert original "style" bushings?

Nothing like a big hack in brand new paint or a bent or damaged fitting or component to ruin your day.

That sounds more involved than pressing sleeves into a cylinder block!

That entire configuration is a mid - 60's application, I have to believe there is a better alternative or other option on the market/available than having to involve such drastic methods, 10 ton hydraulic press, dry ice or liquid nitrogen?

Just to insert original "style" bushings?

Nothing like a big hack in brand new paint or a bent or damaged fitting or component to ruin your day.

Last edited:

- Joined

- Aug 10, 2014

- Messages

- 1,980

BSa Swing Arm Rubber?

Watching this great series Classic Motorcycle Workshop and in today's upload Dave discusses a rubber type of swingarm bearing in a BSA at this point in the viddy: Are these used in many/all BSA's? Other makes?

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

There is no off the shelf easy push in alternative for swing arm bushings in 60's Nortons. The P11 has 4 shorter bushings. Imagine how much fun that must be. Ron would know. I'm only thinking about doing something about it on my P11. I might get as far as trying to polish up the rust damage inside the bushings. A stainless steel spindle might help some, but have not tried one yet.

grandpaul

VIP MEMBER

- Joined

- Jan 15, 2008

- Messages

- 13,251

I used to build 3/4” high grade steel spindles paired with sintered bronze bushings and thrust washers with o-rings to retain the lube a la Commando style. Sold several dozen of those featherbed kits. I don’t see why they couldn’t be tailored to N15/P11 variants

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

Sounds great for an N15. I think the diameter of the spindle and the length of the spindle may be different on a P11, so different parts specs, but certainly doable. I'd have to put the one brain cell I still have to the test to get it done. I'm actually thinking about pulling the swing arm off today. Have to see how far I get on that thinking about part.I used to build 3/4” high grade steel spindles paired with sintered bronze bushings and thrust washers with o-rings to retain the lube a la Commando style. Sold several dozen of those featherbed kits. I don’t see why they couldn’t be tailored to N15/P11 variants

- Joined

- Feb 21, 2013

- Messages

- 121

My wideline featherbed has the early swinging arm, manx style, complete with phosphor bronze bushes.

grandpaul

VIP MEMBER

- Joined

- Jan 15, 2008

- Messages

- 13,251

www.buntinbearings.com for the sintered bronze bushings & thrust washers in pretty much any dimensions you might need...

www.speedymetals.com for the 4140 steel shaft material & end plates.

www.fastenal.com for the hardware & o-rings

You do have to relieve the outside shoulders of the 2 main bushings to form a pocket for the o-rings.

www.speedymetals.com for the 4140 steel shaft material & end plates.

www.fastenal.com for the hardware & o-rings

You do have to relieve the outside shoulders of the 2 main bushings to form a pocket for the o-rings.

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,635

This is a bit off topic, but I did pull my P11 swing arm the other day. The condition of the bushes is OK on the ID and the rubber was not mush. Because it would be a serious PITA to get those bushes out and replace them, I merely cleaned everything up and put it back together. One thing I noted was that with torque removed from the spindle nuts I have about .030 of total slop between the swing arm and frame. I thought about shimming it but that might be overkill and somewhat pointless. Tightening up the spindle nuts to where the clearance is zero the swingarm does not move as smoothly as it should in my opinion. I can get enough torque on the nuts to keep them tight enough to stay on and have a hair's worth of clearance to let the swingarm move freely. Blue loctite required most likely. I think the swingarm needs bearings similar to what is used in the rear hub, not press fit bushes. I don't know how long bearings would last though. Plus I'd still need to get the bushes out. So probably won't get around to it.

What the P11 swingarm looks like. Not as easy to push the bushes out as it is with a Commando swingarm.

What the P11 swingarm looks like. Not as easy to push the bushes out as it is with a Commando swingarm.