Don't bother opening that gearbox. It's dead, Jim.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A journey-1972 Commando Roadster

- Thread starter Beezer Josh

- Start date

I am not sure if all is dead. I agree that all the steel and bushings are likely dead, but you may be able to salvage the inner cover and shell.

Thanks @gortnipper! That was a document I had never seen. It appears the gearchange ratchet is a simple slip in affair, so maybe I'll see if I can get it moving through a little liquid persuasion.I think they have to come off.

I would hit the whole thing with a pressure washer a couple of times and then drop ot in a bucket of deisel for a couple days before having a go.

I have a printed Norton workshop manual as well as the Clymers. Unfortunately everything in this gearbox is frozen and will likely require some sort of destruction for disassembly. Fortunately for me, the inner cover is toast so that decision has been made for me; I'm trying to keep the destruction to that piece. I think some of the frozen iron parts might actually clean up, but disassembly isn't straight forward in its current state. The shaft nut looks like it holds theDetach the shift parts.

Remove the locking ring and remove the clutch pusher parts so the shaft nut underneath can be removed.

Download a manual at the least.

Looking at the exploded parts diagram, it seems that everything could come off with the inner cover, but I was simply looking for verification before taking a cutting wheel and cold chisel to anything.

Don't bother opening that gearbox. It's dead, Jim.

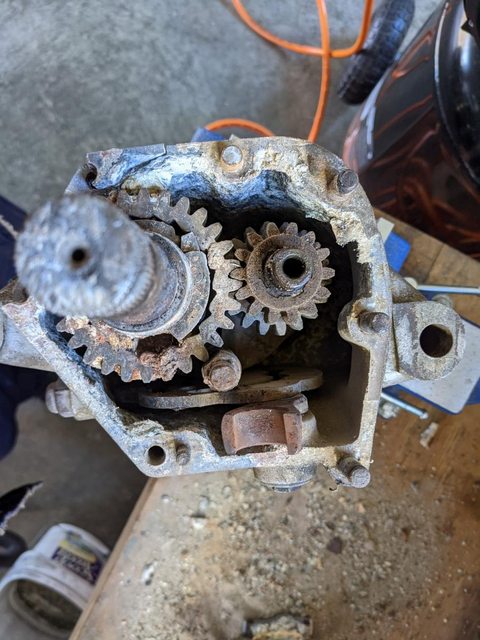

I just got it open. Yeah, it's dead, including the matching numbers case. There's so much corrosion on the aluminum that it's not worth salvaging. There are some pretty thin spots in the metal. I'll do a write up later.I am not sure if all is dead. I agree that all the steel and bushings are likely dead, but you may be able to salvage the inner cover and shell.

Last edited:

grandpaul

VIP MEMBER

The gear cluster cannot come out together as an assembly, they have to be dislodged from the shifter forks, etc.

I have a shifter shaft with ratchet & hairpin spring as spares on a shelf in the shop, let me know if you need them.

I also have other stuff. I'll make up a list.

I have a shifter shaft with ratchet & hairpin spring as spares on a shelf in the shop, let me know if you need them.

I also have other stuff. I'll make up a list.

grandpaul

VIP MEMBER

I can just picture "Bones" with that stare...Don't bother opening that gearbox. It's dead, Jim.

Fast Eddie

VIP MEMBER

All 3 castings already cracked (see post 22).I am not sure if all is dead. I agree that all the steel and bushings are likely dead, but you may be able to salvage the inner cover and shell.

I‘ve drawn a blank trying to hypothesise how those cracks cudda happened.

Any suggestions anyone ?

Last night I spent time preparing my frame for bead blasting. The last time I blasted a frame I did it in a driveway which obviously made a mess. I'm considering farming this out to a local blasting company, or buying a couple of bags of abrasive glass and building a quick and dirty plastic tent to contain everything. I've already got a fairly large compressor and hopper, so the media should be relatively inexpensive.

Down to a bare frame.

I figured that would be a good place to stop for the evening. This morning I woke up with two goals: clean the gutters and get further into the gearbox. Like I said, the inner cover was toast, so no fear in destroying it further. The first thing that came off was the clutch operating lever. That was pretty easy. Next, I went for the pawl carrier assembly. Once I got it to rotate on the ratchet plate shaft, it too came off with relative ease. Next was the ratchet itself. It was free in the cover bush, but the shaft was stuck in the pin roller. After half an hour of trying to wedge it off, out came the torch. After some through heating, it came off a lot easier than I was anticipating.

Making progress.

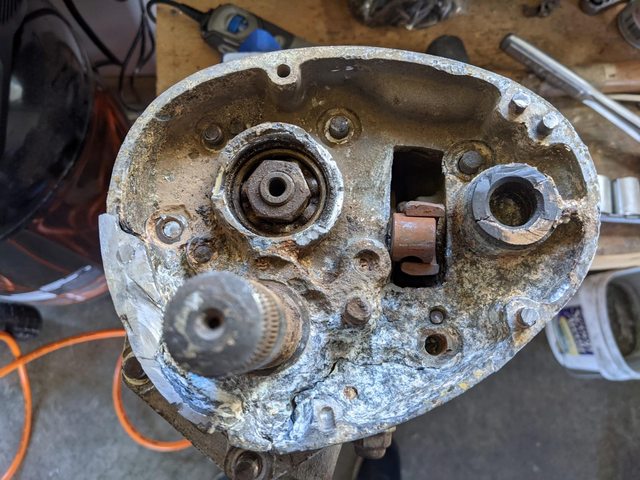

I moved the spring on the kickstart shaft and a bunch of rust came out. I removed the o-ring and bush and the spring came off relatively easily. That just left the lockring and the clutch operating body. I was starting to strip it with a punch, so I began cutting away some of the cover to expose the threads. Some punching later and I was able to wedge it out of the cover and expose the mainshaft nut. You can see the crack in the inner cover more clearly in the photo below.

More corrosion.

I was able to wedge the cover off around the case. Eventually the break in the inner cover gave way and allowed a quick peak into the interior.

Something was holding up the case on the other side.

Eventually the inner cover gave, but took a section of the case with it where the two out nuts are located. The inside looked pitiful. The section of the case that broke off was heavily corroded to the inner case. There were numerous spots inside the case where the corrosion was so bad that the walls of the case looked very thin.

Things are still stuck together, but I'm satisfied that I don't want to use any of the internals in another gearbox.

With everything broken down for the most part, it's now a slow process of blasting, painting, machining, and rebuilding the bike. Posting will be less frequent as I wait for things to come back or be delivered. I'll post questions in the Classic thread as I run into issues or need advice.

Down to a bare frame.

I figured that would be a good place to stop for the evening. This morning I woke up with two goals: clean the gutters and get further into the gearbox. Like I said, the inner cover was toast, so no fear in destroying it further. The first thing that came off was the clutch operating lever. That was pretty easy. Next, I went for the pawl carrier assembly. Once I got it to rotate on the ratchet plate shaft, it too came off with relative ease. Next was the ratchet itself. It was free in the cover bush, but the shaft was stuck in the pin roller. After half an hour of trying to wedge it off, out came the torch. After some through heating, it came off a lot easier than I was anticipating.

Making progress.

I moved the spring on the kickstart shaft and a bunch of rust came out. I removed the o-ring and bush and the spring came off relatively easily. That just left the lockring and the clutch operating body. I was starting to strip it with a punch, so I began cutting away some of the cover to expose the threads. Some punching later and I was able to wedge it out of the cover and expose the mainshaft nut. You can see the crack in the inner cover more clearly in the photo below.

More corrosion.

I was able to wedge the cover off around the case. Eventually the break in the inner cover gave way and allowed a quick peak into the interior.

Something was holding up the case on the other side.

Eventually the inner cover gave, but took a section of the case with it where the two out nuts are located. The inside looked pitiful. The section of the case that broke off was heavily corroded to the inner case. There were numerous spots inside the case where the corrosion was so bad that the walls of the case looked very thin.

Things are still stuck together, but I'm satisfied that I don't want to use any of the internals in another gearbox.

With everything broken down for the most part, it's now a slow process of blasting, painting, machining, and rebuilding the bike. Posting will be less frequent as I wait for things to come back or be delivered. I'll post questions in the Classic thread as I run into issues or need advice.

Poor gearbox. RIP

Larry S

VIP MEMBER

Put a stake in it and put it out of its misery.Poor gearbox. RIP

Well, the purpose of this writeup is to talk about the good with the bad. And by bad, I mean my own mess ups, not necessarily what's happened to the bike in the past. Today was one of those days. I spoke with the media blaster-I've had my share of blasting in a driveway, so I'm good with paying someone to do it now-and he said he could blast my frame and any other parts next Friday for a price I'm more than wiling to pay. After a meeting this morning, I was free to disassemble the remaining bits of the swingarm so they could blast that. Inspired by this post I went to the hardware store to grab some all thread, washers, and nuts. The first side came off without an issue. It was surprisingly easy in fact.

A homemade press.

One side complete.

The next side didn't come out as easily. I got it pressed tight, but couldn't go anymore. I figured a few taps with a hammer might help it along. Eventually it came out.

Two bushes removed.

I don't know why, but I placed it over the gearbox cradle. That's when I realized something was wrong. The two sides were no longer parallel. If you look at the photo, the pressure on the swingarm bent the middle part and the slight "U" shape is visible. Bummer. $79 and another swingarm is on the way. I could bend this one back, but I didn't want to trouble with the alignment, and the price is worth the time and effort.

I moved on to some blasting and plating. I plated most of my BSA fasteners last year with good results so far. I love how well bead blasting cleans up corroded metal. The plating process doesn't remove the corrosion pits any more than painting does, but it is a way to reclaim useable parts and fasteners and I'm not looking for a concours restoration.

In the tank.

Pre polish.

Post polishing with steel wool.

Newly painted and plated.

I think I'll redo the upper one in the photo tomorrow. I don't think I let it plate long enough, and there was an experiment with muriatic acid with that tube.

A homemade press.

One side complete.

The next side didn't come out as easily. I got it pressed tight, but couldn't go anymore. I figured a few taps with a hammer might help it along. Eventually it came out.

Two bushes removed.

I don't know why, but I placed it over the gearbox cradle. That's when I realized something was wrong. The two sides were no longer parallel. If you look at the photo, the pressure on the swingarm bent the middle part and the slight "U" shape is visible. Bummer. $79 and another swingarm is on the way. I could bend this one back, but I didn't want to trouble with the alignment, and the price is worth the time and effort.

I moved on to some blasting and plating. I plated most of my BSA fasteners last year with good results so far. I love how well bead blasting cleans up corroded metal. The plating process doesn't remove the corrosion pits any more than painting does, but it is a way to reclaim useable parts and fasteners and I'm not looking for a concours restoration.

In the tank.

Pre polish.

Post polishing with steel wool.

Newly painted and plated.

I think I'll redo the upper one in the photo tomorrow. I don't think I let it plate long enough, and there was an experiment with muriatic acid with that tube.

At this point the best you can hope for is a good used or rebuildable box. It's not even worth extracting the bushes, even if you could.Hurricane bike ?

The bronze bushes might be OK.

Thanks GP. I'm trying to reclaim as many parts as is practical. I appreciate the offer, but I've already blasted and painted this head steady, so I'll stick with it. All rubber bits and bearings will be replaced as a matter of course, but I'll try to reuse any of the fasteners and frame components that are in good condition by stripping and plating or painting them.

Fast Eddie

VIP MEMBER

Thanks GP. I'm trying to reclaim as many parts as is practical. I appreciate the offer, but I've already blasted and painted this head steady, so I'll stick with it. All rubber bits and bearings will be replaced as a matter of course, but I'll try to reuse any of the fasteners and frame components that are in good condition by stripping and plating or painting them.

Good on yer.

that head steady is a well known failure point. the best place for it is the scrap metal bin before it breaks. do your self a favor and replace it as it is a safety issue.Thanks GP. I'm trying to reclaim as many parts as is practical. I appreciate the offer, but I've already blasted and painted this head steady, so I'll stick with it. All rubber bits and bearings will be replaced as a matter of course, but I'll try to reuse any of the fasteners and frame components that are in good condition by stripping and plating or painting them.