- Joined

- Sep 27, 2022

- Messages

- 34

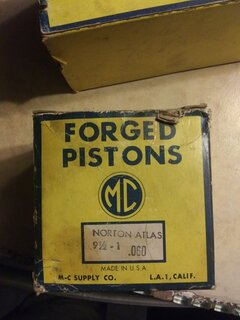

I've got these .060" over MC Forged pistons that I'd like to use in my Atlas. The current barrel is already .040" over and in rough shape, so I think it would be a good contender. Does anyone have a feel for what the piston-wall clearance should be?