Hi All, does anyone know what i am doing wrong here , decided to fit new cam chain so removed sprockets with chain, nut was really tight , there was a champhered edge washer behind the cam sprocket which i removed and replaced again hopefully the correct way round i have the champhered edge toward the sprocket, replaced sprockets with new chain and every time i try to tighten nut i cant seem to turn over engine everything goes tight , can anyone help, also what is torque setting for nut

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

camshaft nut

- Thread starter brf1957

- Start date

- Status

- Not open for further replies.

- Joined

- Dec 10, 2008

- Messages

- 7,253

There should not be a washer behind the camshaft sprocket. The only chamfered washer that should be on a Norton camshaft is the one inside the case next to the tach drive gear. If someone installed that washer behind the sprocket then the cases need to be split to put it where it belongs. You can tell if it has been left out by looking down the tach drive hole after removing the tach drive. Jim

- Joined

- Oct 19, 2005

- Messages

- 18,978

Maybe the extra washer is pushing sprocket out of line of chain so new chain w/o much slack is binding the cogs on bush binding? Check the oil pump cog is spinning free and not wobby to bind under chain tension. Maybe you got the sprockets misaligned for valve train hang up?

Holmeslice

VIP MEMBER

- Joined

- Sep 27, 2009

- Messages

- 490

brf1957 said:Hi Jim ,Didnt want to hear that , will have a look through tacho drive tomorrow, still cant understand why everything is going tight when i tighten nut, when all i have done is replace chain

Because, if your spacer is not on the inside, as you tighten you have pulled the entire cam over to the right and the RH lobe is being pulled up tight against the timing side cam bushing. Or worse, the lobes are hitting the mouth of the case.

But as I think about it more, if this were the case, I don't know how it could have ever run this way in the past.

Is the cam sprocket being located by the small woodruff key in the cam?

Hi all , Have discovered that if i tighten camshaft nut pulling camshaft hard against whatever, and then loosen nut and tap camshaft back the other way it moves about 1mm this champher edged washer is about 3mm which leads me to think this one woudnt fit in there anyway unless it sits in a recess maybe someone could tell me this, also i have done about 3000 miles on this bike since i got it like this, would i have noticed something before now if washer was missing from inside

DogT

VIP MEMBER

- Joined

- Jan 20, 2009

- Messages

- 7,394

You had better check inside like Jim says. There is no washer on the cam outside the timing cover as I remember, just the one inside. I'm pretty sure the cam sprocket just butts up against the shoulder on the cam. These bikes will run seemingly fine with all sorts of things wrong with them until something drastic happens.

http://www.oldbritts.com/1971_g1.html

Dave

69S

http://www.oldbritts.com/1971_g1.html

Dave

69S

Hi thanks for advice DogT ,another thing i have just discovered is only engines up to no. 200000 had this champhered thrust washer, as my engine is no.304142 i am assuming it has the double washers with tabs in there, and someone for some unknown reason has put this champhered one behind the sprocket

I think you assume wrong. I believe you should have cam bushing # 06-3020 seen here http://www.oldbritts.com/cam_bush.html on motors after 300000.. This will requiere only the beveled thrust washer as the cam bushing 063020 is shouldered. God only know what someone else has done before you though.brf1957 said:Hi thanks for advice DogT ,another thing i have just discovered is only engines up to no. 200000 had this champhered thrust washer, as my engine is no.304142 i am assuming it has the double washers with tabs in there, and someone for some unknown reason has put this champhered one behind the sprocket

DogT

VIP MEMBER

- Joined

- Jan 20, 2009

- Messages

- 7,394

Check out this http://www.oldbritts.com/cam_bush.html it explains the bushings and washers.

my engine number is 132031 and I have the chamfered bushing.

Dave

69S

my engine number is 132031 and I have the chamfered bushing.

Dave

69S

Been looking through the manual i got with the bike part no, 063419 and in there it tells you about the thrust washer behind the cam sprocket , have now discovered that this is not the manual for the 850, previous owner was obviously using this book and fitted the washer in there ,i am just hoping he put the one on the other side of the case ,looks like the only way im going to find out is to open up which im trying to avoid , i have measured camshaft end float and have 1mm and cant see that there would be room for the champhered washer to fit in there, so im assuming there is one in there already or can anyone tell me is 1mm to much

Holmeslice

VIP MEMBER

- Joined

- Sep 27, 2009

- Messages

- 490

brf1957 said:Been looking through the manual i got with the bike part no, 063419 and in there it tells you about the thrust washer behind the cam sprocket , have now discovered that this is not the manual for the 850, previous owner was obviously using this book and fitted the washer in there ,i am just hoping he put the one on the other side of the case ,looks like the only way im going to find out is to open up which im trying to avoid , i have measured camshaft end float and have 1mm and cant see that there would be room for the champhered washer to fit in there, so im assuming there is one in there already or can anyone tell me is 1mm to much

As Comnoz said in the first responding post, remove the tach drive and shine your flashlight in there and see if you can spot the chamfered washer between the cam lobe and the cam bushing.

- Joined

- Dec 10, 2008

- Messages

- 7,253

All Commando engines with a tach drive in the engine case instead of externally mounted to the timing case used the chamfered washer on the cam.

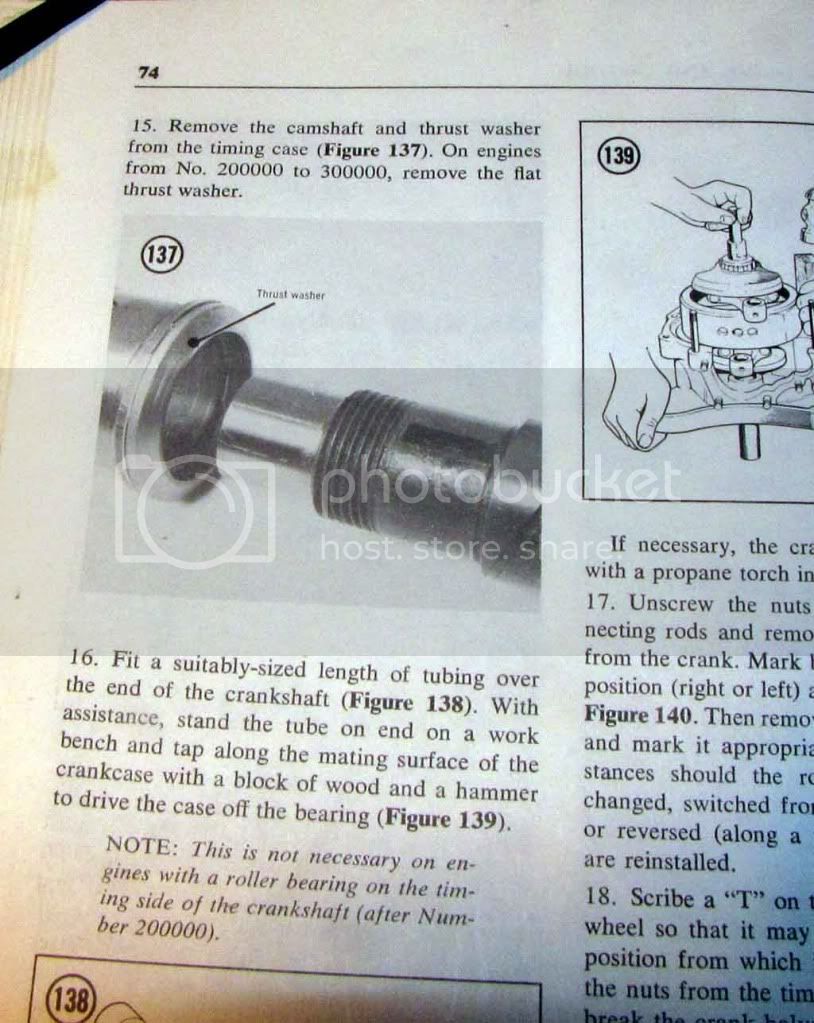

It should be next to the gear that is machined into the cam inside the engine case. It would keep the gear from damaging the cam bushing. The earlier engines you were referring to also had a tab washer between the chamfered washer and the inside of the case and another between the case and the timing sprocket. That was the tab washer that commonly failed and caused engine damage. It was replaced with a 2 piece cam bushing with a shoulder made on it but still had the chamfered washer inside the case.

If the engine is assembled with the chamfered washer between the sprocket and the bushing it will lock the cam unless the chamfer is installed toward the bushing. Then the cam will be free to turn but will damage the bushing and miss-align the cam drive sprockets.

The chamfered washer must be installed inside the cases with the taper toward the gear so the flat side contacts the bushing. Jim

It should be next to the gear that is machined into the cam inside the engine case. It would keep the gear from damaging the cam bushing. The earlier engines you were referring to also had a tab washer between the chamfered washer and the inside of the case and another between the case and the timing sprocket. That was the tab washer that commonly failed and caused engine damage. It was replaced with a 2 piece cam bushing with a shoulder made on it but still had the chamfered washer inside the case.

If the engine is assembled with the chamfered washer between the sprocket and the bushing it will lock the cam unless the chamfer is installed toward the bushing. Then the cam will be free to turn but will damage the bushing and miss-align the cam drive sprockets.

The chamfered washer must be installed inside the cases with the taper toward the gear so the flat side contacts the bushing. Jim

- Joined

- Jan 20, 2011

- Messages

- 893

Hey brf1957, Hope everything comes out ok, I am reading this with great interest as I am in the midst of some unexpected repairs of my own. see... Compound Fracture of the Crankcase., And have noticed that the Camshaft nut on my engine was loose and that there seems to be about 1mm of play in the shaft. Can anyone tell me what the acceptable maximum movement would be. I also wonder if,.... the nut being loose, would it turn under revs, then possibly turn the other way on slow down, (blipping the throttle) giving more end play thus creating enough movement of the Cam to be a problem to the Followers.!!

Hi,had a bit of difficulty trying to see into tacho drive hole but managed to set up a mirror and with torch, and i am sure i am seeing the champhered washer which is a relief , will be leaving off the one that was behind the sprocket as this was obviously causing the chain to be out of line, noticed on the tensioner after further investigation that the marks left by chain were slightly at an angle so have ditched that one in favour of a rubber pad one ,so all back together again will get her fired up again when i get some oil tomorrow . thanks to all who gave advice will give you an update when i get back on the road this week Brian

- Status

- Not open for further replies.