jms

VIP MEMBER

- Joined

- Jul 26, 2005

- Messages

- 183

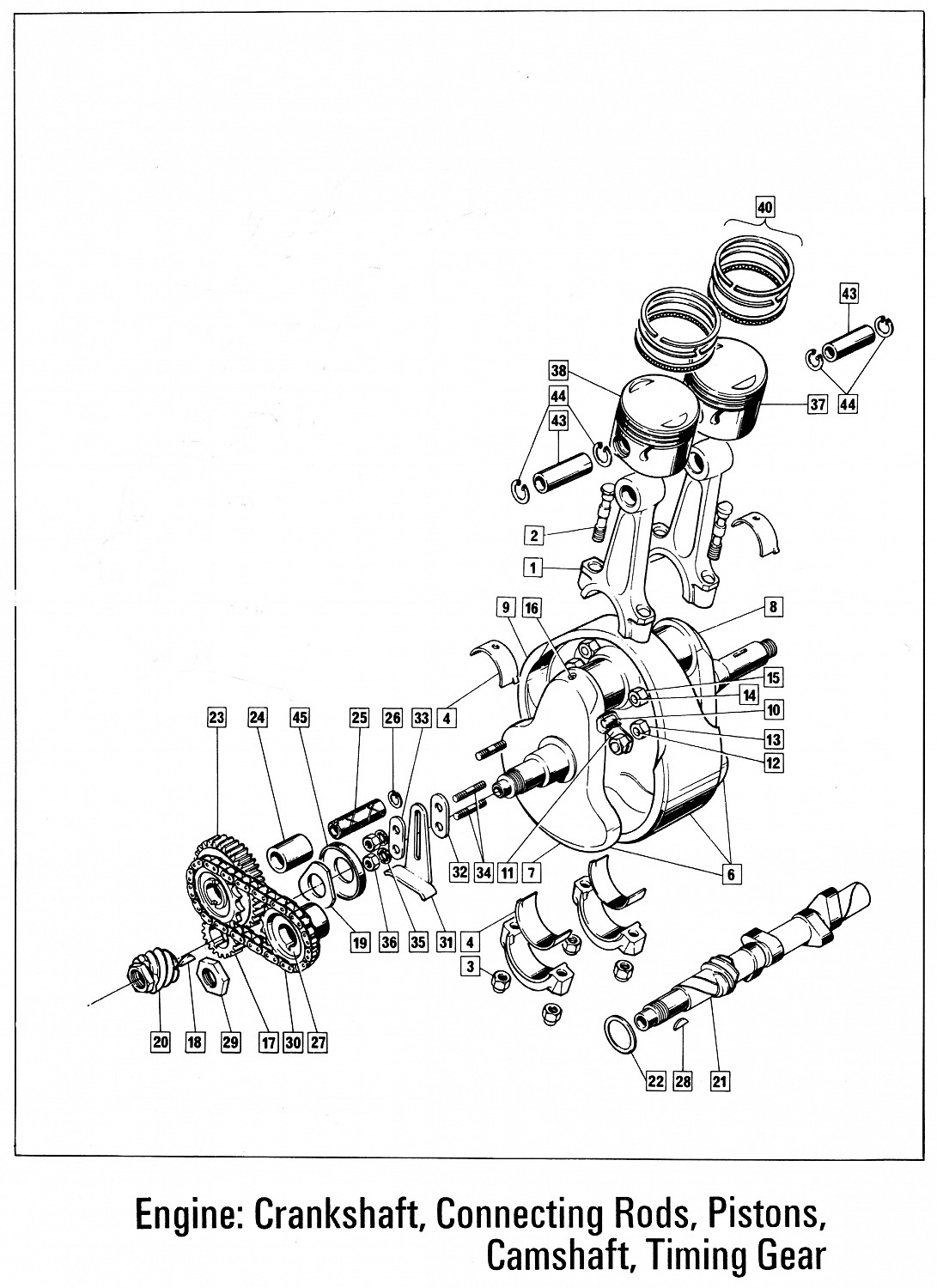

I received a crankshaft fixing kit from RGM and was finally getting around to installing it after having had the journals ground. The kit which was identified for all engines pre 212,278, which mine is. My crank when I took it apart had 4 bolts and two studs. The studs were the two lower ones joined by the tab washers. The new kit is all studs and nuts but the tab washers aren't long enough to connect the two lower studs. Anybody have and experience with this? RGM has another kit for engines post 212,278 but very clearly say that the two kits are interchangable. So why have two kits?