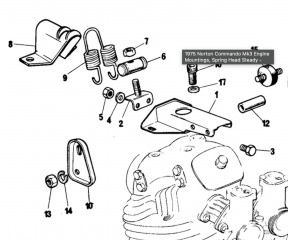

Is anyone aware of work being done to validate the upward force of these springs?

My 650 engine weighs 43kg - not sure what a commando engine weighs?

If you knew the "spring constant" (k) for that spring and the amount of deflection of the spring required for it to fit over the spring saddle and under the trunnion (x) you could work out how much upward force it generates.

I wonder how close it comes to neutralising the engine weight?

Then, of course, there's the fact that the spring isn't acting vertically (looks to be about 20 degrees) which would mean that if it were to magically have 43kg equivalent force, only 40kg would act vertically and 15kg would act horizontally forward.

So, maybe like statically balancing these engines, there is a compromise to be made.

Someone (was it comnoz?) put a compression spring under the engine, acting off a cross-member.