N0rt0nelectr@

VIP MEMBER

- Joined

- Sep 15, 2014

- Messages

- 1,190

I expect this has been discussed before but I can't find the link. Late last year I had the sprag go out on my CNW starter. Matt as I said before was right on it and sent me a new one. The sprag was easy enough to install and I hadn't touched a thing timing wise. Then I decided to replace the oil pump with a new one I had sitting on my shelf. I replaced the seals and reset my timing per Pazon's instructions. I didn't touch the timing chain. Now it get interesting.

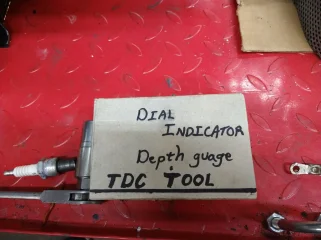

Before the timing mark was spot on. Now when I measure the advance on the piston it's no where close. If I set it up using the timing mark and checking that against the piston it is way off and runs terrible. I am sure I'm missing something simple but what it is. When setting it up with the piston at 5/16"BTDC it starts and runs just fine. Like I said it's weird.

Ideas, suggestions?

Thanks

John in Texas

Before the timing mark was spot on. Now when I measure the advance on the piston it's no where close. If I set it up using the timing mark and checking that against the piston it is way off and runs terrible. I am sure I'm missing something simple but what it is. When setting it up with the piston at 5/16"BTDC it starts and runs just fine. Like I said it's weird.

Ideas, suggestions?

Thanks

John in Texas