- Joined

- Apr 15, 2009

- Messages

- 11,520

So I got the spindles out. Video in the other thread.

I pulled the rockers and associated stuff out to inspect (and clean). Not sure what I think of these parts.

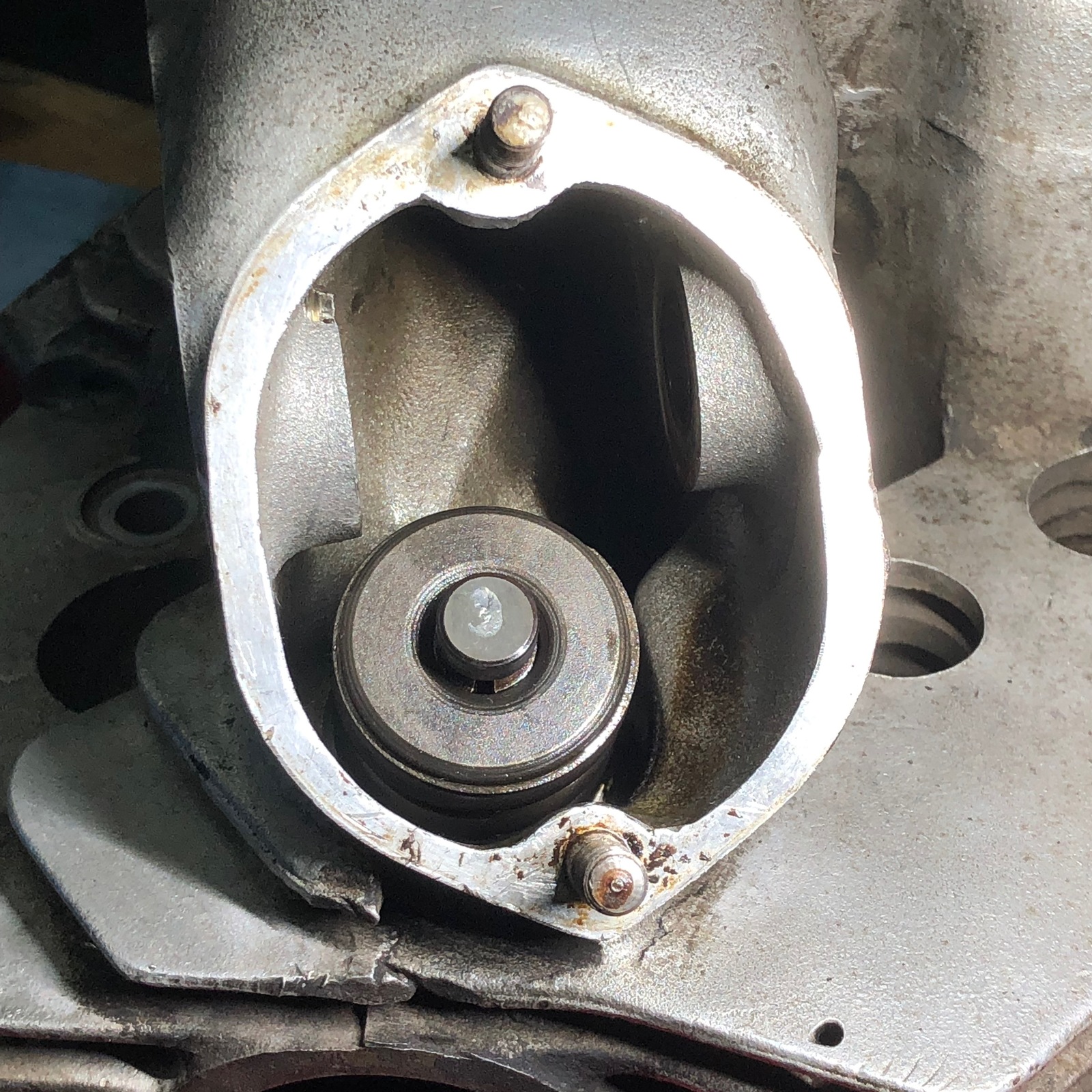

Right Exhaust. The valve cap wouldn't come off (I didn't try very hard). The Left Exhaust Cap cap off easily. Is this acceptable wear?

Left Exhaust. Time to replace?

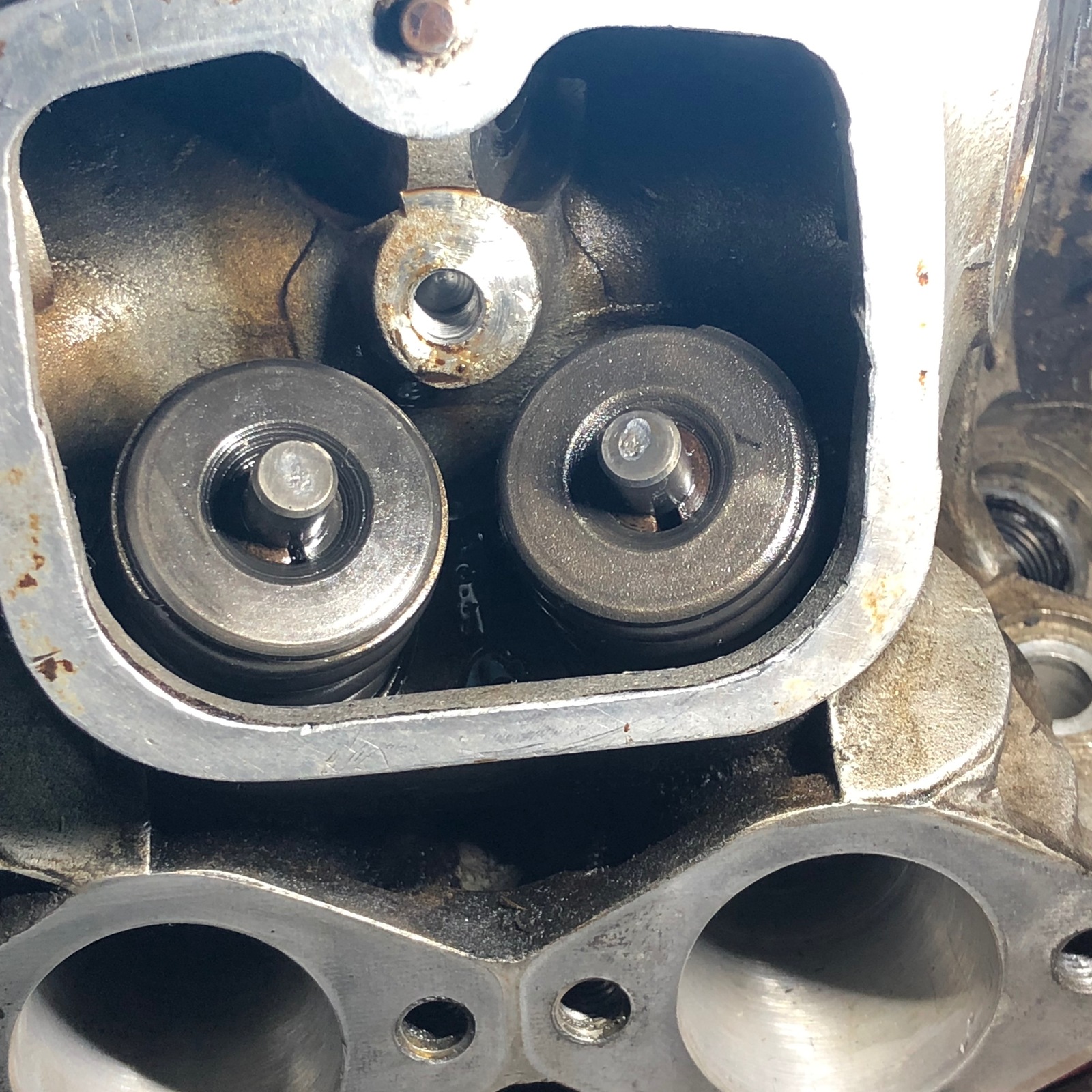

Intake Valves. There isn't a cap on these? Also one side the rocker didn't have a shim. Only one shim and the spring. I looked everywhere for the shim. Could not find. Is that unusual?

I pulled the rockers and associated stuff out to inspect (and clean). Not sure what I think of these parts.

Right Exhaust. The valve cap wouldn't come off (I didn't try very hard). The Left Exhaust Cap cap off easily. Is this acceptable wear?

Left Exhaust. Time to replace?

Intake Valves. There isn't a cap on these? Also one side the rocker didn't have a shim. Only one shim and the spring. I looked everywhere for the shim. Could not find. Is that unusual?