- Joined

- Jan 27, 2015

- Messages

- 64

My 2013 CR at only 2400mls is undergoing engine blue printing at the moment, not really because of any single apparent issue, other than noise, vibration and the feeling that things were not quite right.

Started with the primary side, doing all the prerequisite fundamentals... new split gear spring, peg the clutch ring gear... heavier oil (which I don't recommend BTW), checked valves, adjusted timing chain - no noticeable difference.

Digging deeper - found the balance shaft roller bearing toast.

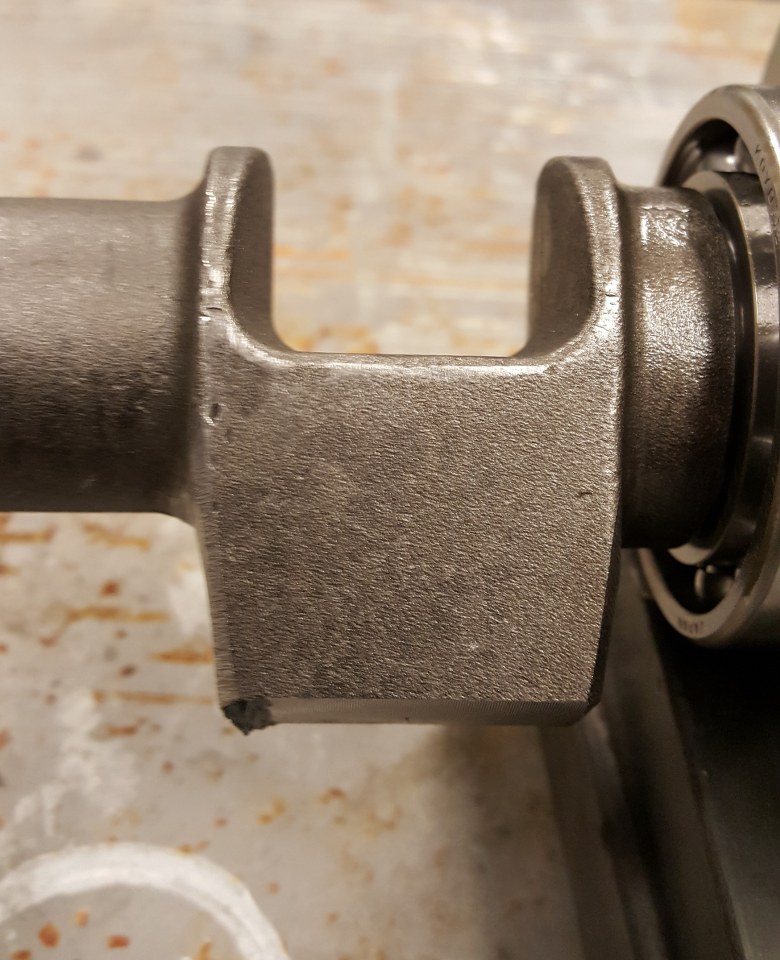

Digging deeper again - found the crankshaft centre main mounting plate not tight, allowing the crank to deflect, resulting in a 6 thou out of true. This is an factory assembly issue that Norton UK are not keen to talk about.

Norton Canada provided new roller bearing, gaskets and paid for the crank to be trued as a goodwill gesture. Norton UK said in no uncertain terms - you are on your own, we don't support individuals undertaking their own work (even out of warranty). I have written directly to Norton UK, they are aware of these issues and to date have not made any comment, or even acknowledged that these issues are "known". They have never had the courtesy to reply to my emails either.

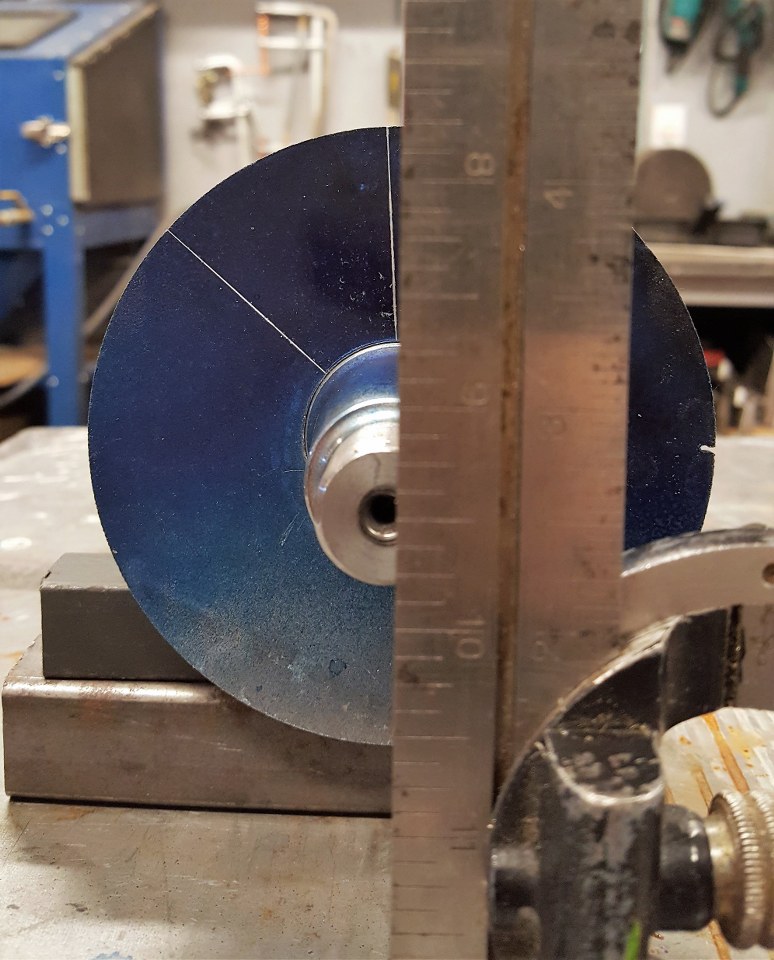

Moving along - I thought I would look at the balance shaft itself, as I had heard these cast/forged ones can be out of spec... well yes indeed - bob weights were mismatch causing a 4 1/2 deg offset - I had to grind one of the weights quite substantially to get the shaft to align with the vertical axis. - Not a big deal, but wondering if this had a part to play in the balance shaft roller bearing failure.

I am re-posting a number of the photos of the early tear-down and some new ones of the balance shaft work.. you might find this interesting to follow.

A note to other Owners - It is clear there are probably some "factory manufacturing issues" on certain bikes, maybe batches of bikes. Yes the out of spec issues I have found seem alarming, BUT in all honesty, these issues may never manifest during the ownership of the bike - we are all told "live with (expect) engine noise and vibration" I chose to dig deep into what is going on inside the engine and although there were some surprises, it can be put right with minimal cost of parts, and a chunk of time. I doubt if the bikes would ever "blow up" as a result of the these issues, just the running may slowly show signs of change. A dealer has no reason to dig this deep if an owner comes and says bike vibrates and makes noise, I guarantee Norton would not sanction it as it is the tip of a slippery slope for them.

There is so much good information on making these bikes run the way they were meant to. Besides a new roller bearing, trued crank, new main bearings, balanced balance shaft, vented primary, I will be installing all the BOSCH sensor upgrades, new BOSCH coils and the special plug wires. The ECU has been flashed with the latest maps. To me this is work I am undertaking is the best investment in being able to enjoy this bike long into the future. After all it was "Hand-built at Donnington Hall" and now "Hand-built" again in Canada..

You can view the previous images of the engine tear down

View post on imgur.com

Started with the primary side, doing all the prerequisite fundamentals... new split gear spring, peg the clutch ring gear... heavier oil (which I don't recommend BTW), checked valves, adjusted timing chain - no noticeable difference.

Digging deeper - found the balance shaft roller bearing toast.

Digging deeper again - found the crankshaft centre main mounting plate not tight, allowing the crank to deflect, resulting in a 6 thou out of true. This is an factory assembly issue that Norton UK are not keen to talk about.

Norton Canada provided new roller bearing, gaskets and paid for the crank to be trued as a goodwill gesture. Norton UK said in no uncertain terms - you are on your own, we don't support individuals undertaking their own work (even out of warranty). I have written directly to Norton UK, they are aware of these issues and to date have not made any comment, or even acknowledged that these issues are "known". They have never had the courtesy to reply to my emails either.

Moving along - I thought I would look at the balance shaft itself, as I had heard these cast/forged ones can be out of spec... well yes indeed - bob weights were mismatch causing a 4 1/2 deg offset - I had to grind one of the weights quite substantially to get the shaft to align with the vertical axis. - Not a big deal, but wondering if this had a part to play in the balance shaft roller bearing failure.

I am re-posting a number of the photos of the early tear-down and some new ones of the balance shaft work.. you might find this interesting to follow.

A note to other Owners - It is clear there are probably some "factory manufacturing issues" on certain bikes, maybe batches of bikes. Yes the out of spec issues I have found seem alarming, BUT in all honesty, these issues may never manifest during the ownership of the bike - we are all told "live with (expect) engine noise and vibration" I chose to dig deep into what is going on inside the engine and although there were some surprises, it can be put right with minimal cost of parts, and a chunk of time. I doubt if the bikes would ever "blow up" as a result of the these issues, just the running may slowly show signs of change. A dealer has no reason to dig this deep if an owner comes and says bike vibrates and makes noise, I guarantee Norton would not sanction it as it is the tip of a slippery slope for them.

There is so much good information on making these bikes run the way they were meant to. Besides a new roller bearing, trued crank, new main bearings, balanced balance shaft, vented primary, I will be installing all the BOSCH sensor upgrades, new BOSCH coils and the special plug wires. The ECU has been flashed with the latest maps. To me this is work I am undertaking is the best investment in being able to enjoy this bike long into the future. After all it was "Hand-built at Donnington Hall" and now "Hand-built" again in Canada..

You can view the previous images of the engine tear down

View post on imgur.com

Last edited: