- Joined

- Nov 26, 2009

- Messages

- 3,080

I’ve been interested in one way breathers ever since the 1980s when Leo Goff used them on his world championship dragster. I tried them but was never happy with the fit until now. This new one way breather fits inside the timing cover so you don’t have to drill holes in the exterior of your cases (potential leaks near the rear tire). For 850s you retain the original breather to the oil tank. For 750s you plug the original cam vent and transfer the elbow fitting to the mag blank plate and plumb it to the oil tank. All necessary hardware is provided. No machine work is necessary but you have to drill and tap threads.

For more info go here:

http://www.jsmotorsport.com/technical_breather.asp

The naked breather with German steel reed valve and 7075 aircraft aluminum housing:

As its mounted in the timing case.

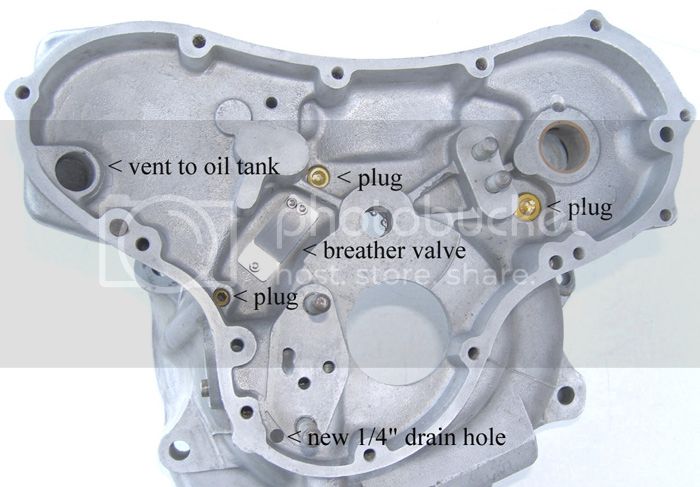

With all the case plugs installed:

Positive pressure is pumped out when the pistons descend. Then the valve shuts and prevents the air from re-entering on the upstroke creating a temporary vacuum. Now there is very little air to be pumped out on the next down stroke. Without the air pressure pumping in and out - leaks are reduced or eliminated throughout the motor.

Demo video here:

[video]https://youtu.be/1YAjg7X763Y[/video]

For more info go here:

http://www.jsmotorsport.com/technical_breather.asp

The naked breather with German steel reed valve and 7075 aircraft aluminum housing:

As its mounted in the timing case.

With all the case plugs installed:

Positive pressure is pumped out when the pistons descend. Then the valve shuts and prevents the air from re-entering on the upstroke creating a temporary vacuum. Now there is very little air to be pumped out on the next down stroke. Without the air pressure pumping in and out - leaks are reduced or eliminated throughout the motor.

Demo video here:

[video]https://youtu.be/1YAjg7X763Y[/video]