You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pre unit alternator adaptor

- Thread starter steko

- Start date

- Joined

- Dec 3, 2012

- Messages

- 3,672

What year generator engine. ? (I do not know if the rigid engine is the same as the swing arm engine in those measurements ? maybe only the primary cover length is different)

My 1957 TR6 engine is stripped down to have the crankshaft ground, if the same I could get those measurements with the mill DRO.

My 1957 TR6 engine is stripped down to have the crankshaft ground, if the same I could get those measurements with the mill DRO.

- Joined

- Oct 25, 2018

- Messages

- 20

Engine case no is 5T 05096 , therefore it should be 1957 , too.What year generator engine. ? (I do not know if the rigid engine is the same as the swing arm engine in those measurements ? maybe only the primary cover length is different)

My 1957 TR6 engine is stripped down to have the crankshaft ground, if the same I could get those measurements with the mill DRO.

- Joined

- Dec 3, 2012

- Messages

- 3,672

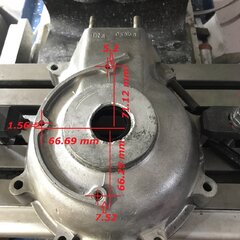

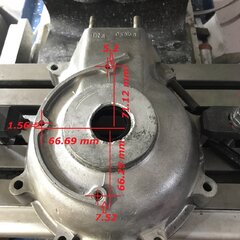

My cases are damaged at the centre so I machined an insert to fit the bearing bore so I could clock the centre.

It reminds me I need to make some kind of oil seal holder as I have the belt drive to fit.

The cylinder top was clocked as level.

The bearing centre is Zero.

Some of threads need some attention, perhaps the same previous owner worked their magic here also.

Click for Full Size.

It reminds me I need to make some kind of oil seal holder as I have the belt drive to fit.

The cylinder top was clocked as level.

The bearing centre is Zero.

Some of threads need some attention, perhaps the same previous owner worked their magic here also.

Click for Full Size.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,633

Welding a machined ring to the case would be my preferred option (and what I’ve done before) as it adds considerable strength to the most stressed part of the (very old) case.

However, if welding ain’t yer thang, this might inspire:

However, if welding ain’t yer thang, this might inspire:

TRIUMPH PRE-UNIT DRIVE SIDE OIL SEAL CONVERSION | eBay

Using our own CNC Milling machine we re-machine the worn chain case face and bearing seat face on the drive side so both are flat. We then machine the hole bigger to allow the oil to drain back through the bearing.

www.ebay.co.uk

- Joined

- Oct 25, 2018

- Messages

- 20

My cases are damaged at the centre so I machined an insert to fit the bearing bore so I could clock the centre.

It reminds me I need to make some kind of oil seal holder as I have the belt drive to fit.

The cylinder top was clocked as level.

View attachment 80234

The bearing centre is Zero.

View attachment 80235

Some of threads need some attention, perhaps the same previous owner worked their magic here also.

View attachment 80236

Click for Full Size.

View attachment 80237

Time Warp, many many thanks for what you did for me !!!

I am not sure.... The angle between the 3 holes is 90 deg ?

There are helicoils fitted in my engine case to 'repair' those threads.

- Joined

- Oct 25, 2018

- Messages

- 20

Eddie, thank you for the comment, but i have already a oil seal connversion.Welding a machined ring to the case would be my preferred option (and what I’ve done before) as it adds considerable strength to the most stressed part of the (very old) case.

However, if welding ain’t yer thang, this might inspire:

TRIUMPH PRE-UNIT DRIVE SIDE OIL SEAL CONVERSION | eBay

Using our own CNC Milling machine we re-machine the worn chain case face and bearing seat face on the drive side so both are flat. We then machine the hole bigger to allow the oil to drain back through the bearing.www.ebay.co.uk

- Joined

- Oct 25, 2018

- Messages

- 20

For those who ask WHY ?

I can not use a triumph primary case. My engine plates allow a minimum distance about 273,5mm , maximum about 293,5mm, between the shaft centres of the crankshaft and the transmission. The clutch diameter, is 172mm (Bob Newby). I think the triumph chain cases are too short.

I can not use a triumph primary case. My engine plates allow a minimum distance about 273,5mm , maximum about 293,5mm, between the shaft centres of the crankshaft and the transmission. The clutch diameter, is 172mm (Bob Newby). I think the triumph chain cases are too short.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,633

I was answering TW...Eddie, thank you for the comment, but i have already a oil seal connversion.

- Joined

- Dec 3, 2012

- Messages

- 3,672

Time Warp, many many thanks for what you did for me !!!

I am not sure.... The angle between the 3 holes is 90 deg ?

There are helicoils fitted in my engine case to 'repair' those threads.

It is close to 90 deg based off the cylinder face as level so holes rotated slightly.

The bottom hole is off a little but that one had a Helicoil in my engine case, I will try a good inner primary cover to see.

- Joined

- Dec 3, 2012

- Messages

- 3,672

Welding a machined ring to the case would be my preferred option (and what I’ve done before) as it adds considerable strength to the most stressed part of the (very old) case.

However, if welding ain’t yer thang, this might inspire:

TRIUMPH PRE-UNIT DRIVE SIDE OIL SEAL CONVERSION | eBay

Using our own CNC Milling machine we re-machine the worn chain case face and bearing seat face on the drive side so both are flat. We then machine the hole bigger to allow the oil to drain back through the bearing.www.ebay.co.uk

Yes I will make something like that. perhaps not as robust.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,633

Yeah it looks a bit OTT !Yes I will make something like that. perhaps not as robust.

- Joined

- Oct 25, 2018

- Messages

- 20

Time Warp,It is close to 90 deg based off the cylinder face as level so holes rotated slightly.

The bottom hole is off a little but that one had a Helicoil in my engine case, I will try a good inner primary cover to see.

View attachment 80262

thanks a lot for the great support !

Best wishes

Ste