- Joined

- Dec 2, 2017

- Messages

- 49

Could use a little advise/help on a 75 MKIII.

Bike has not run in six years.

I've done the basic's - engine oil change, check/adjust valves, check/set timing, rebuild carb's, etc..

Dealing with a issue in the Primary.

I've flushed the primary oil a few times but continued to hear, what to me sounded like a chain rub noise at around 3K to 5K rpm while going through each gear.

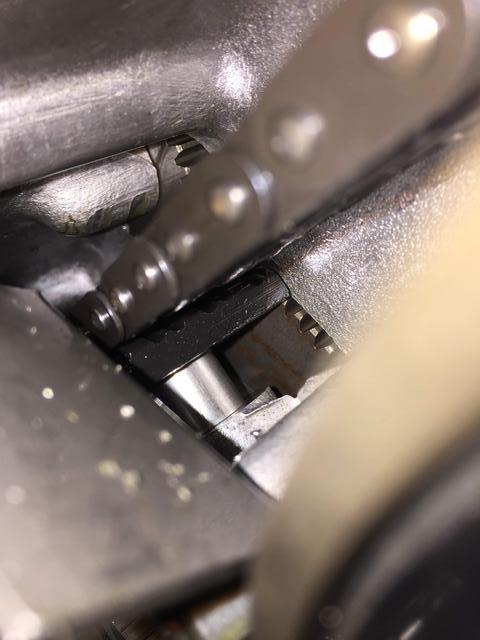

Pulled the cover and found this.

Second pic shows what I may have been hearing.

I've read a couple posts on this but am hoping someone could school me on how much I need to disassemble to get at and check the oil passage's on the top & bottom tensioners. Seems like I also read about a check valve in the manual too.

I'm assuming the top one is not getting oil to hold it in a tensioned position? Allowing a slackened chain to rub agaisn't the lower case.

One issue at a time getting this back on the road.

Thanks in advance, Ken

Wear Marks

Top Tensioner

Bottom Tensioner

Bike has not run in six years.

I've done the basic's - engine oil change, check/adjust valves, check/set timing, rebuild carb's, etc..

Dealing with a issue in the Primary.

I've flushed the primary oil a few times but continued to hear, what to me sounded like a chain rub noise at around 3K to 5K rpm while going through each gear.

Pulled the cover and found this.

Second pic shows what I may have been hearing.

I've read a couple posts on this but am hoping someone could school me on how much I need to disassemble to get at and check the oil passage's on the top & bottom tensioners. Seems like I also read about a check valve in the manual too.

I'm assuming the top one is not getting oil to hold it in a tensioned position? Allowing a slackened chain to rub agaisn't the lower case.

One issue at a time getting this back on the road.

Thanks in advance, Ken

Wear Marks

Top Tensioner

Bottom Tensioner