- Joined

- Feb 26, 2022

- Messages

- 92

Hi all,

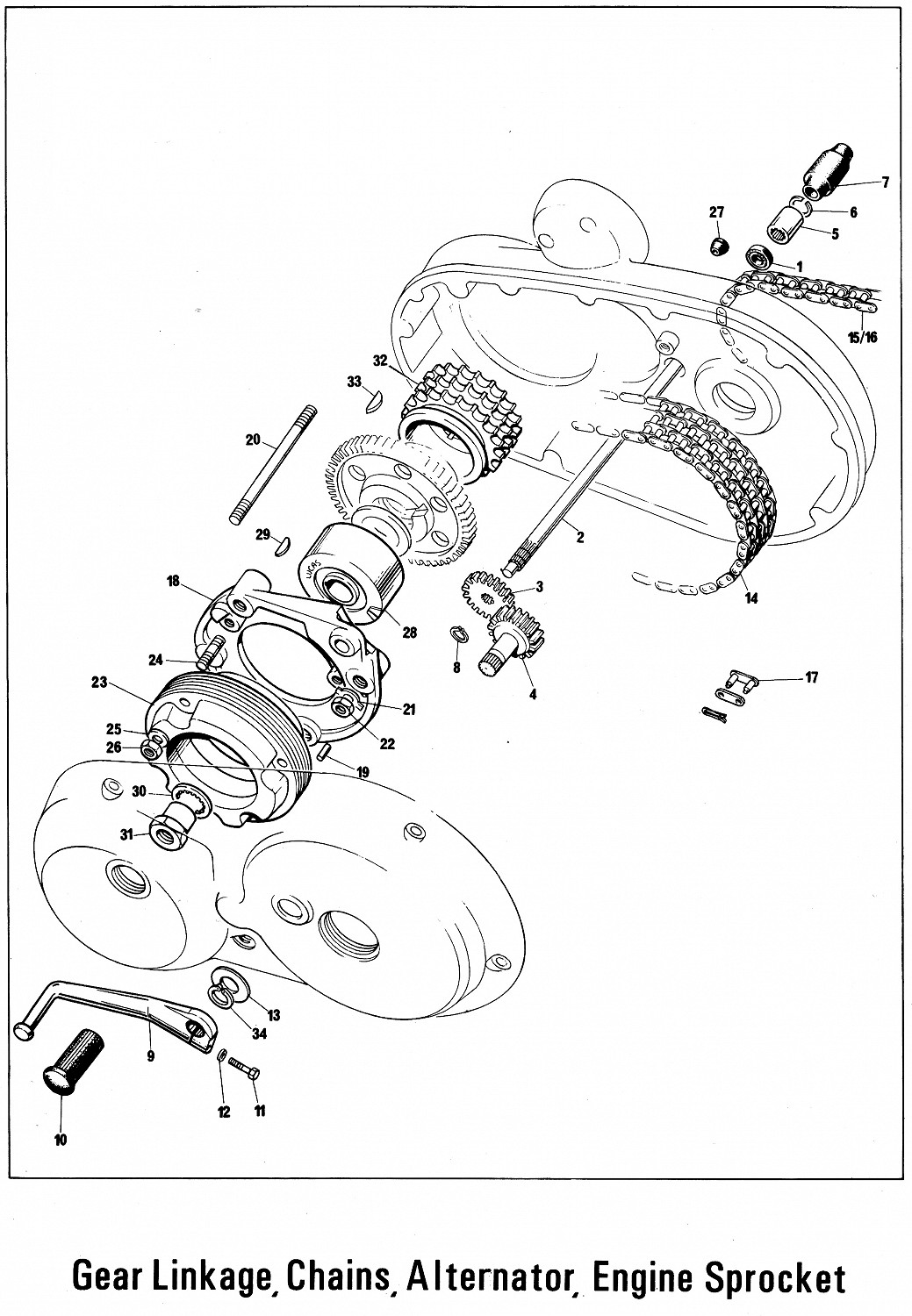

I have been restoring an MKIII Commando over the past several months. I couldn't have come as far as I have without the knowledge people have shared through this incredible forum. But for the first time I have come across an issue I can't seem to find information on, and was hoping for some help. To start things off I have an MKIII (Dec '74 manufacture) that I have stripped down almost completely to clean and inspect parts, replace all the oil seals and questionable bearings, etc.

Well I finally got my primary assembly put back together this weekend only to discover that my primary case and gearbox are fairly out of alignment, causing the cross shaft to take on an uncomfortable looking skew. But it seems like the distance between the gearbox and engine is pretty fixed. I've tried slacking the drive chain and loosening all the bolts at the gearbox cradle to see if I can wiggle the gearbox and/or cradle forward a bit, but it doesn't seem to have much affect. The gearbox, cradle, and engine are all original to the bike.

Has anyone encountered this issue before? I have attached some pictures of the situation. Any help would really be appreciated, and if I've left out any important information I'll be glad to clarify or answer any questions.

Thank you,

Anthony

I have been restoring an MKIII Commando over the past several months. I couldn't have come as far as I have without the knowledge people have shared through this incredible forum. But for the first time I have come across an issue I can't seem to find information on, and was hoping for some help. To start things off I have an MKIII (Dec '74 manufacture) that I have stripped down almost completely to clean and inspect parts, replace all the oil seals and questionable bearings, etc.

Well I finally got my primary assembly put back together this weekend only to discover that my primary case and gearbox are fairly out of alignment, causing the cross shaft to take on an uncomfortable looking skew. But it seems like the distance between the gearbox and engine is pretty fixed. I've tried slacking the drive chain and loosening all the bolts at the gearbox cradle to see if I can wiggle the gearbox and/or cradle forward a bit, but it doesn't seem to have much affect. The gearbox, cradle, and engine are all original to the bike.

Has anyone encountered this issue before? I have attached some pictures of the situation. Any help would really be appreciated, and if I've left out any important information I'll be glad to clarify or answer any questions.

Thank you,

Anthony