jimbo

VIP MEMBER

- Joined

- Sep 25, 2004

- Messages

- 1,921

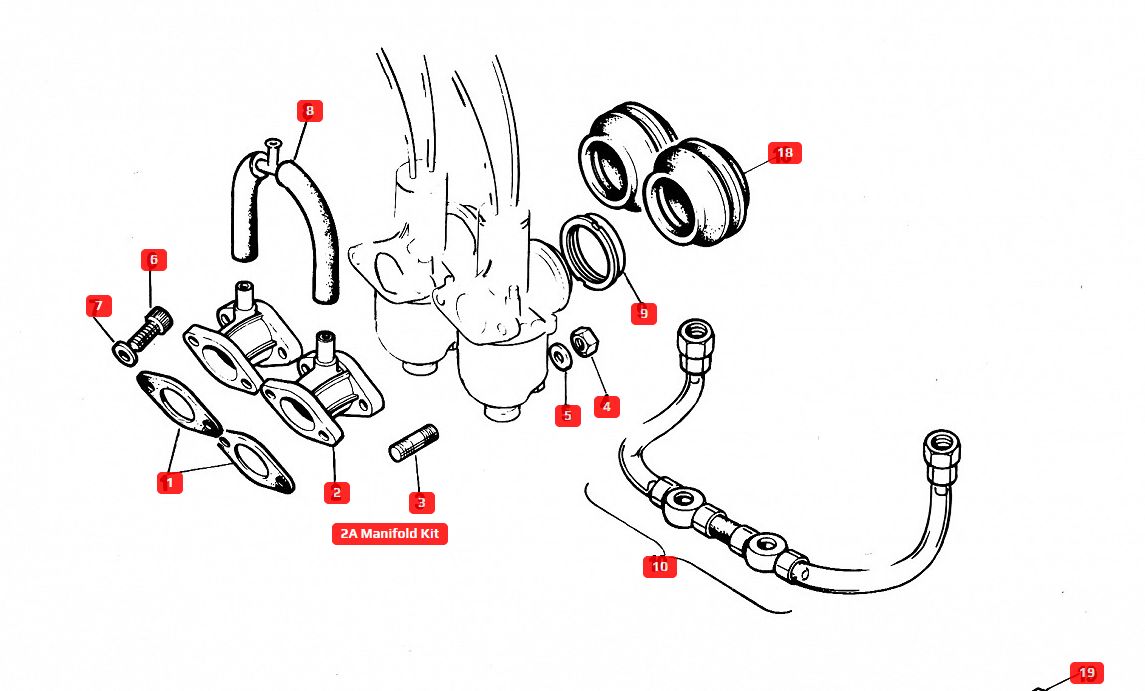

I struggled to get the rubber boots fit on the carbs and plastic air box on the JPN( same as a MK3 almost) I would have rather installed the carbs! What a PITA Then I noticed it looks like I installed the threaded rings on the carbs the wrong way around. Doing it that way seem to give me more rubber between the carbs and air box to work with. I thought about removing the air box door and filter element and threading my hand into the air box to work the rubbers into their grooves but that seemed to be a non starter. Any tricks putting these silly things on?