You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

leaky master cyl cap

- Thread starter maylar

- Start date

- Status

- Not open for further replies.

- Joined

- Nov 20, 2004

- Messages

- 20,081

Do both caps have the same thread?

Did they both have the 'paper' washer (not in the parts books) when used?

Do you mean the original bellows? If so, then I suggest you replace it with the later diaphragm (which must be folded before fitting).

Did they both have the 'paper' washer (not in the parts books) when used?

Norton Spare Parts - Genuine Norton Parts - Norton Motor - Norton Motorcycle - Norton Commando

Norton Spare Parts: We manufacture parts in our own workshops. We measure, test and inspect a selection of components from all inward deliveries.

andover-norton.co.uk

The rubber bellows looks to be perfect - why would it not seal?

Do you mean the original bellows? If so, then I suggest you replace it with the later diaphragm (which must be folded before fitting).

Motorcycle parts and spares for Norton motorbikes - Genuine Andover Norton Spare Parts - Andover Norton Motorcycles Parts - Original Andover Norton Parts

Motorcycle parts and spares for Andover Norton motorbikes: Andover Norton manufactures and supplies all Genuine Factory Spare Parts for Norton motorcycles built before 2002.

andover-norton.co.uk

o0norton0o

VIP MEMBER

- Joined

- Apr 27, 2015

- Messages

- 1,743

Sometimes if you goose the cap too tightly, it pushes the lip of the rubber bellows off the lip of the reservoir. After ruining the paint on my roadster tank 3 times over the years, I had enough of that and bought the "madass140" produced replacement master cylinder which has the bosses to mount the standard commando switch blocks. It doesn't leak and has great feel.

I can't keep repainting my bike every few years when the lockheed master leaks again... I don't care if my commando isn't stock parts.

I can't keep repainting my bike every few years when the lockheed master leaks again... I don't care if my commando isn't stock parts.

maylar

VIP MEMBER

- Joined

- May 13, 2007

- Messages

- 4,213

Do both caps have the same thread?

Yes.

Did they both have the 'paper' washer (not in the parts books) when used?

Norton Spare Parts - Genuine Norton Parts - Norton Motor - Norton Motorcycle - Norton Commando

Norton Spare Parts: We manufacture parts in our own workshops. We measure, test and inspect a selection of components from all inward deliveries.andover-norton.co.uk

Uhh.. no. Didn't know there was such a thing. Maybe I can make one.

Do you mean the original bellows? If so, then I suggest you replace it with the later diaphragm (which must be folded before fitting).

Mine is new-ish, and yes needs to be folded in. That's what I refer to as a bellows.

cliffa

VIP MEMBER

- Joined

- May 26, 2013

- Messages

- 3,797

Are they plastic or alloy caps? The plastic ones (which I seem to remember were only fitted to Triumphs originally) seem to be a bit loose on the thread to me, so probably lead to over tightening.I have 2 caps for the Lockheed master cylinder front brake reservoir. One leaks fluid around the edges (down the threads) and the other leaks through the vent hole on top. The rubber bellows looks to be perfect - why would it not seal?

- Joined

- Nov 20, 2004

- Messages

- 20,081

The plastic ones (which I seem to remember were only fitted to Triumphs originally

And 850 Mk.3 (front and rear) but a different plastic cap.

cliffa

VIP MEMBER

- Joined

- May 26, 2013

- Messages

- 3,797

Thanks L.A.B.And 850 Mk.3 (front and rear) but a different plastic cap.

jaydee75

VIP MEMBER

- Joined

- Jul 2, 2012

- Messages

- 962

Wow, all these years and I never knew there was a paper gasket and I didn't know to fold the bellows up.

Gonna go do that right now, and add some fluid. There wasn't much room for brake fluid with the bellows extended and

I always griped about it. Thanks LAB.

Jaydee

Gonna go do that right now, and add some fluid. There wasn't much room for brake fluid with the bellows extended and

I always griped about it. Thanks LAB.

Jaydee

- Joined

- Mar 7, 2020

- Messages

- 3,157

I bought one of the (ex Harris?) 13mm rear cylinders with the white plastic reservoir. Came with a gasket which looked like waxed cardboard! First ride out was the last time I saw new cap, bellows and gasket :-( Must be a moral in there somewhere? Always used to bitch that the OE cap was a pain to remove, but at least it came home every time..

- Joined

- Nov 20, 2004

- Messages

- 20,081

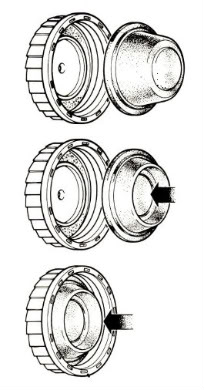

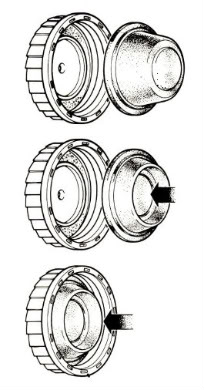

Looking at my photo of the 061946 bellows I noticed the sealing lip is taller and has a tapered profile compared to the flat-faced lip of the diaphragm which got me thinking that perhaps the paper washer wasn't used with the original bellows but is required for the diaphragm?

Bellows:

Diaphragm:

Edit:

850 Mk.3 reservoir with thread for the plastic cap.

Bellows:

Diaphragm:

Edit:

850 Mk.3 reservoir with thread for the plastic cap.

Last edited:

- Joined

- Mar 7, 2020

- Messages

- 3,157

With the OE jobbie I had no gasket but treated it like an oil filter, turn 'til it nips then just a bit more. And like an oil filter it needed a strap to remove :-(

maylar

VIP MEMBER

- Joined

- May 13, 2007

- Messages

- 4,213

One is stainless, the other is chromed alloy. Both fit tightly.Are they plastic or alloy caps?

I wonder if the paper washer keeps the cap from grabbing the top of the diaphragm and distorting it as you tighten?

- Joined

- Nov 20, 2004

- Messages

- 20,081

What is the actual purpose of the diaphragm? I don't see it in other applications.

Jaydee

The hydraulic reservoir has to be able to 'breathe' to allow for the fall (from pad wear) and rise (from system expansion) in fluid level (and why there's a hole in the cap).

The bellows/diaphragm is a flexible barrier that prevents moisture in the air from contaminating the fluid.

If the fluid level drops due to pad wear or leakage then the diaphragm begins to unfold, so prevents the remaining fluid from sloshing.

cliffa

VIP MEMBER

- Joined

- May 26, 2013

- Messages

- 3,797

I would wipe the upper side of the diaphragm flange with red brake grease or some brake fluid, and just nip it up.One is stainless, the other is chromed alloy. Both fit tightly.

I wonder if the paper washer keeps the cap from grabbing the top of the diaphragm and distorting it as you tighten?

- Joined

- Feb 12, 2013

- Messages

- 1,555

I used to have that problem. My fix was to remove the [ later ] diaphragm from the cap and fit it evenly on the m/cyl. Fit the cap and nip it tightish by hand, I can always undo mine by hand. I Don't have any problems now and god knows how old that diaphragm is. I don't use any rubber grease or such like. I only check it about once a year so can't remember if I used the same technique last time. I suspect that when the diaphragm is inserted in the cap, there is room for it to slip sideways.

Dereck

Dereck

Larry S

VIP MEMBER

- Joined

- Apr 15, 2020

- Messages

- 681

I agree with the above statement. I do quite a bit of plumbing and there are paper washers used just for that purpose. For instance, on a kitchen sink drain the strainer is inserted through the bottom of the sink with putty around the flange. From underneath goes a rubber washer then a paper washer. After that goes the nut that tightens it all together. If you don’t install the paper washer when you tighten the nut it distorts and will not seal well resulting in a leak. The paper washer allows the nut to spin freely without grabbing the rubber seal and distorting it. Just a thought.One is stainless, the other is chromed alloy. Both fit tightly.

I wonder if the paper washer keeps the cap from grabbing the top of the diaphragm and distorting it as you tighten?

- Status

- Not open for further replies.