- Joined

- Oct 28, 2014

- Messages

- 1,996

what grit is recommended for ring break in? I am sure there are many answers. I am using emgo pistons with cast iron rings most of the time

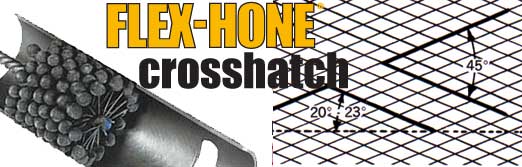

In general, the guidance by piston ring makers (Hastings, etc) is that if the original cylinder crosshatch is visible, no honing is necessary; if it's not visible, honing to establish a crosshatch IS necessary. Hand drill-operated brush hones are typically used in the home garage for this purpose though most reputable builders don't like them due to the imprecise nature of the manual operation.

Brush hones have been around donkeys years, even I've used them."some major race engine builders do a final finish with a brush hone."

That's interesting. I'm surprised that any high performance/competition engine builder would hone a cylinder to final finish with a brush/electric drill. My gut reaction is that it sounds like a heart surgeon using a swiss army knife!OTOH I quit doing that stuff professionally 10-12 years ago so it sounds like my thoughts and experience are out of date. Oh well, that's the way of the world; things change...

Didn't this method go out with the ark?!I use coarse sandpaper and work at an angle in the bore from both ends. Good wash afterwards.