You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head steady

- Thread starter Qside

- Start date

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

Easy enough to make one out of local hardware store 1/4" x 1" aluminum flat stock . I used the original steel head steady that was in the basket of my basket case '67 P11 as a template. No problems with fit if custom made. 1/4" x 1" aluminum flat stock is plenty strong enough for use on the street.

I'm not sure how much energy it would take to bend the frame enough to make the OEM head steady 1/4" short, but I suspect a lot. Also not sure how the motor could be mounted in such as way as to move the motor 1/4" further back in the frame.

I'm not sure how much energy it would take to bend the frame enough to make the OEM head steady 1/4" short, but I suspect a lot. Also not sure how the motor could be mounted in such as way as to move the motor 1/4" further back in the frame.

- Joined

- Apr 20, 2011

- Messages

- 5,773

Looks like Commando timing cover, is the engine Commando too?Head steady straps are the same for all three frame types, P11, P11A, and Ranger 750. Something must be out of line.

Also looks like not orginal engine plates ?

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

Or somebody messed up the threads in the head steady mount at the frame, welded it up, and drilled and tapped a new mount 1/4 inch too far forward from the head.I realize that, but There is no bend in the frame and the engine seems to be mounted correctly... that is what is puzzling us.

Last edited:

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

The head steady mount at the head is a bolt on my P11 motor. I don't have a clue what the thread is, but I would imagine Andover knows. It's the same thread as the early Commando head. I had a Commando head on my motor for a while, and everything bolted up except I had to change the oil feed lines to reach the side rocker feeds on the head. I believe I also had to put inserts in the barrels to accommodate the larger diameter head bolts close to the plugs

Last edited:

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

Memory is not perfect. I did the head swap on and off around 1990, so based on Ron's correction, I apparently used a different bolt in the Commando head. I know I did not use a stud for the head steady on either head. I actually went out and checked a minute ago.

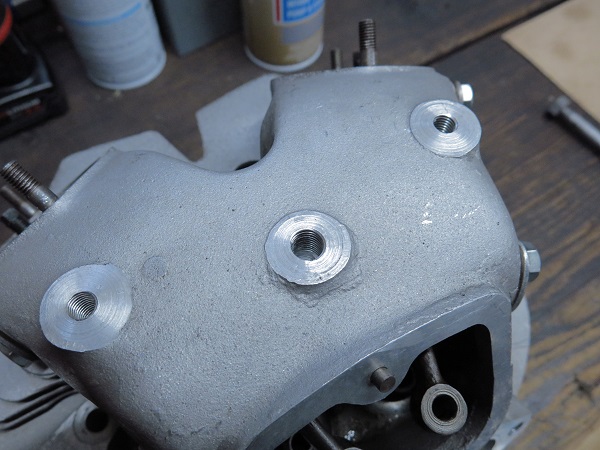

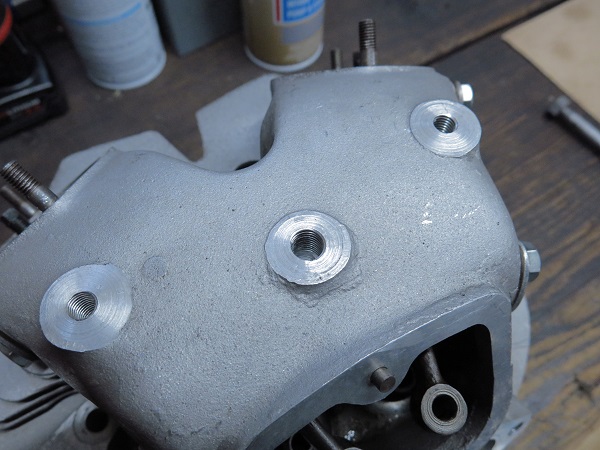

Edit: The thread in the center mounting hole of the 3 head steady mounting bosses in the Commando head I have (shown below) is 3/8-BSF. So I was "correct" about the head steady mount threads and bolt I used on my P11 being the same in both heads in my case. I verified it with a 3/8-BSF stud I had that fit. The two outer head steady holes in the Commando head I have are smaller and could be 5/16 BSF. I did not verify threads on those outer holes, since they are not used for the P11 head steady.

Top view of the Commando head I have: (The rocker oil feeds are on the sides of this head. It is not a P11 or Atlas head.)

While on the wrong ideas path... It is highly doubtful that the frame mount location for the head steady was welded up, re-drilled, and threaded 1/4" off. It would be really obvious.

Edit: The thread in the center mounting hole of the 3 head steady mounting bosses in the Commando head I have (shown below) is 3/8-BSF. So I was "correct" about the head steady mount threads and bolt I used on my P11 being the same in both heads in my case. I verified it with a 3/8-BSF stud I had that fit. The two outer head steady holes in the Commando head I have are smaller and could be 5/16 BSF. I did not verify threads on those outer holes, since they are not used for the P11 head steady.

Top view of the Commando head I have: (The rocker oil feeds are on the sides of this head. It is not a P11 or Atlas head.)

While on the wrong ideas path... It is highly doubtful that the frame mount location for the head steady was welded up, re-drilled, and threaded 1/4" off. It would be really obvious.

Last edited:

Ron L

VIP MEMBER

- Joined

- Feb 27, 2004

- Messages

- 3,204

It appears the center hole in that head has been drilled and tapped for a larger bolt. All three holes are the same size and thread on a stock Commando head.Memory is not perfect. I did the head swap on and off around 1990, so based on Ron's correction, I apparently used a different bolt in the Commando head. I know I did not use a stud for the head steady on either head. I actually went out and checked a minute ago.

Edit: The thread in the center mounting hole of the 3 head steady mounting bosses in the Commando head I have (shown below) is 3/8-BSF. So I was "correct" about the head steady mount threads and bolt I used on my P11 being the same in both heads in my case. I verified it with a 3/8-BSF stud I had that fit. The two outer head steady holes in the Commando head I have are smaller and could be 5/16 BSF. I did not verify threads on those outer holes, since they are not used for the P11 head steady.

Top view of the Commando head I have: (The rocker oil feeds are on the sides of this head. It is not a P11 or Atlas head.)

While on the wrong ideas path... It is highly doubtful that the frame mount location for the head steady was welded up, re-drilled, and threaded 1/4" off. It would be really obvious.

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

I thought the same after you provided the thread info. I only know about what I have in my possession and am able to verify outside of a forum message box. I merely wanted to show why I said what I said earlier.It appears the center hole in that head has been drilled and tapped for a larger bolt. All three holes are the same size and thread on a stock Commando head.

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 2,622

Do you think if I just loosen the bolts there is enough slack?

Surprises me that this was not tried already.