You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Follower scar oil tests (2018)

- Thread starter comnoz

- Start date

- Status

- Not open for further replies.

click

VIP MEMBER

- Joined

- Dec 27, 2008

- Messages

- 1,010

Hello All

Just for info samples of these UK/Euro oils will be winging their way to Jim over the next couple of weeks for testing:

If any UK/Europe based owners are interested or would like further details or to contribute please open a conversation with me.

- Total/elf Moto 4 Race 10w-60 API SN fully synthetic.

- Millers Classic Sport High Performance 20w-50 (described as full ZDDP) API SL/CF fully synthetic.

- Comma Classic 20w-50 (800 ppm ZDDP), oil requested by sponsor API SE CC Mineral based.

- Fuchs Silkolene Comp 4 20w-50, API SL synthetic ester based (semi-synthetic).

- Castrol Power 1 4T 20w-50 - API SJ Refers to ZDDP but no level available (probably semi synthetic). <<-differs from V-Twin

- Duckhams Q 20w-50 (has 1200 ppm ZDDP) API SJ/C Mineral based classic with good ZDDP.

- Fuchs Titan Pro S 10w-60. API SL, SJ & SH fully synthetic.

- Rock Oil Synthesis Motorcycle 10w-50. API SN fully synthetic.

Andy

Hi Andy,

Appreciate you organising this for all of us on the other side of the pond, some funds sent to help with the cost, hopefully a few others will chip in.

Kevin

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,641

I don't find any Active 8 available on this side of the pond. Looks like a UK thing only.

Some on its way...

SteveA

VIP MEMBER

- Joined

- Dec 20, 2011

- Messages

- 3,280

...........

Now, be a good person and go Donate to Jim (top of oil page) and then go and sign up as an A/N VIP member.

Cheers

Jerry, I don't see the donate link!

Jerry Doe

Admin

- Joined

- May 21, 2003

- Messages

- 2,237

Hi Steve,

It is at the top of the page here: https://www.accessnorton.com/Oil-Tests/NortonOil.php

Cheers

It is at the top of the page here: https://www.accessnorton.com/Oil-Tests/NortonOil.php

Cheers

Last edited:

Jerry Doe

Admin

- Joined

- May 21, 2003

- Messages

- 2,237

Might want to post a warning somewhere in the database for the less experienced users that any of the low friction oils would be an extremely poor choice for breaking in a rebuilt engine that uses cast iron rings.

Maybe. Its a work in progress. I have been working on it for a few days so going to have a rest away from it now. I am heading out for a ride, cheers

- Joined

- Jul 20, 2017

- Messages

- 387

Colour me doubly impressed …

NoLongerHere

VIP MEMBER

- Joined

- Apr 2, 2013

- Messages

- 749

Following this with interest, I made a comment about the stuff earlier in the posts (page 1).Jim, this just keeps getting better and better !

I used to use a friction reducer called “Active 8”. They do the show circuits in the U.K. doing a scar test type stunt.

I watched them closely trying to figure out how they were cheating the tests, but I couldn’t see anything. They convinced me enough to use it for years. I stopped when I started using Redline as I concluded “they know best and I don’t want to screw with their formula”. After your test, I’m re-thinking my conclusions for the additive AND the oil!

Anyway, can you let me know if Active 8 is availabe in the US? I’d really like to see how it works when added to the best oil we can find.

If it’s available in US I’m happy to fund the cost. If it’s not, I’m happy to send some to you. Please let me know either way.

https://www.activ8lubricants.com/

It looked too good to be true when tested, it even "worked" when drained off.

Last edited:

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,641

I’d missed your comment on this Cab!

Great minds think alike eh?

Well, I’ve sent some to Jim, so we’ll see if those test we were impressed by were real after all!

Great minds think alike eh?

Well, I’ve sent some to Jim, so we’ll see if those test we were impressed by were real after all!

- Joined

- Dec 10, 2008

- Messages

- 7,253

I have completed setting up calculations for "heat from friction"

This is a computer generated number that replaces the cooling fan duty cycle which was sometimes affected by the length of the test.

I have edited the earlier results to show this. They will be edited in the database soon.

Less than 1 would be insignificant heat and friction -very good as long as this does not go along with a load rating that is too low.

~1 to 5 would be a good range in an air cooled motor.

10 would be severe heat.

Here are two more oils

___________________________________________________________

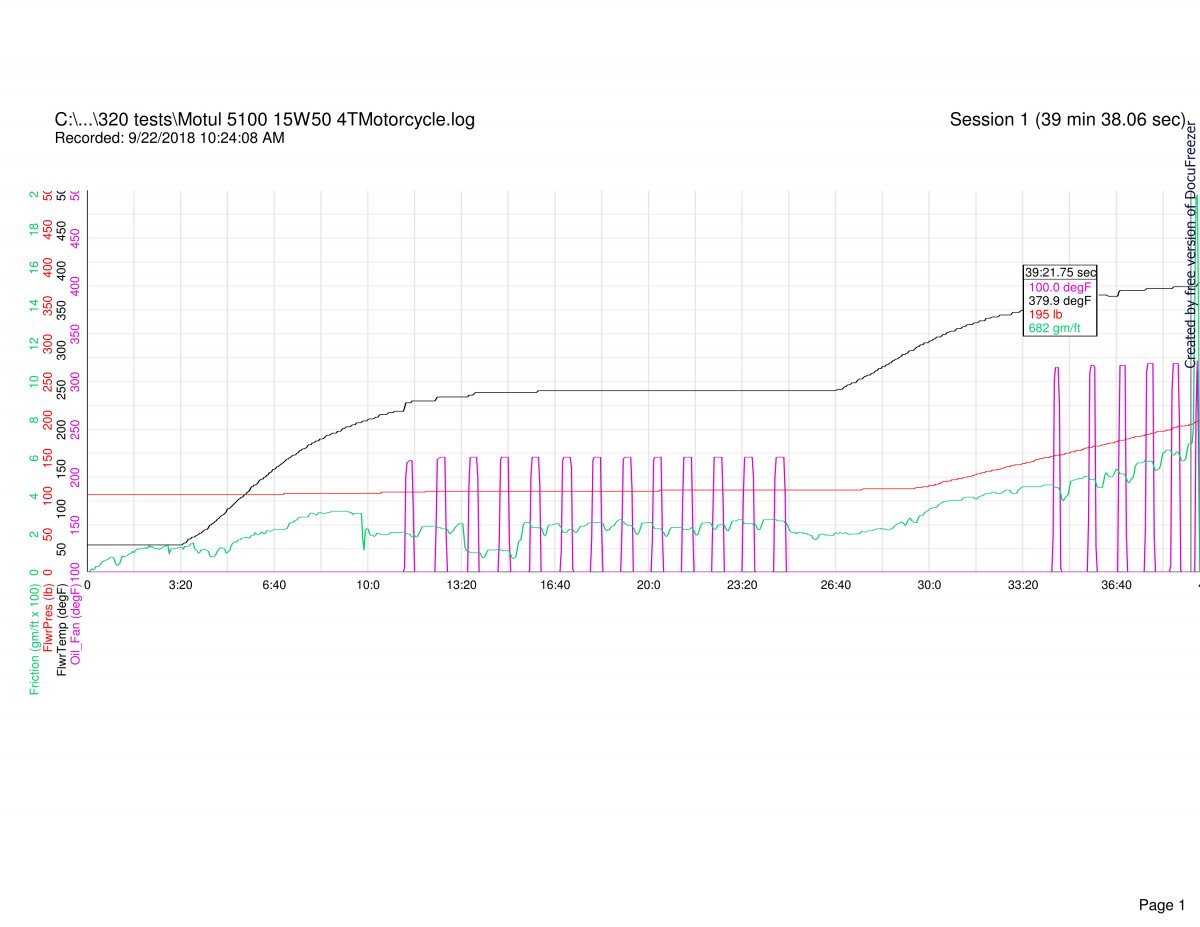

Motul_5100_15W50_4T_Motorcycle_Synthetic_blend

195 lbs load

3.47 heat from high pressure shear

4.9 heat from friction

Medium/ high heat from friction.

Safe for wet clutch

Good oil for Norton

__________________________________________________________

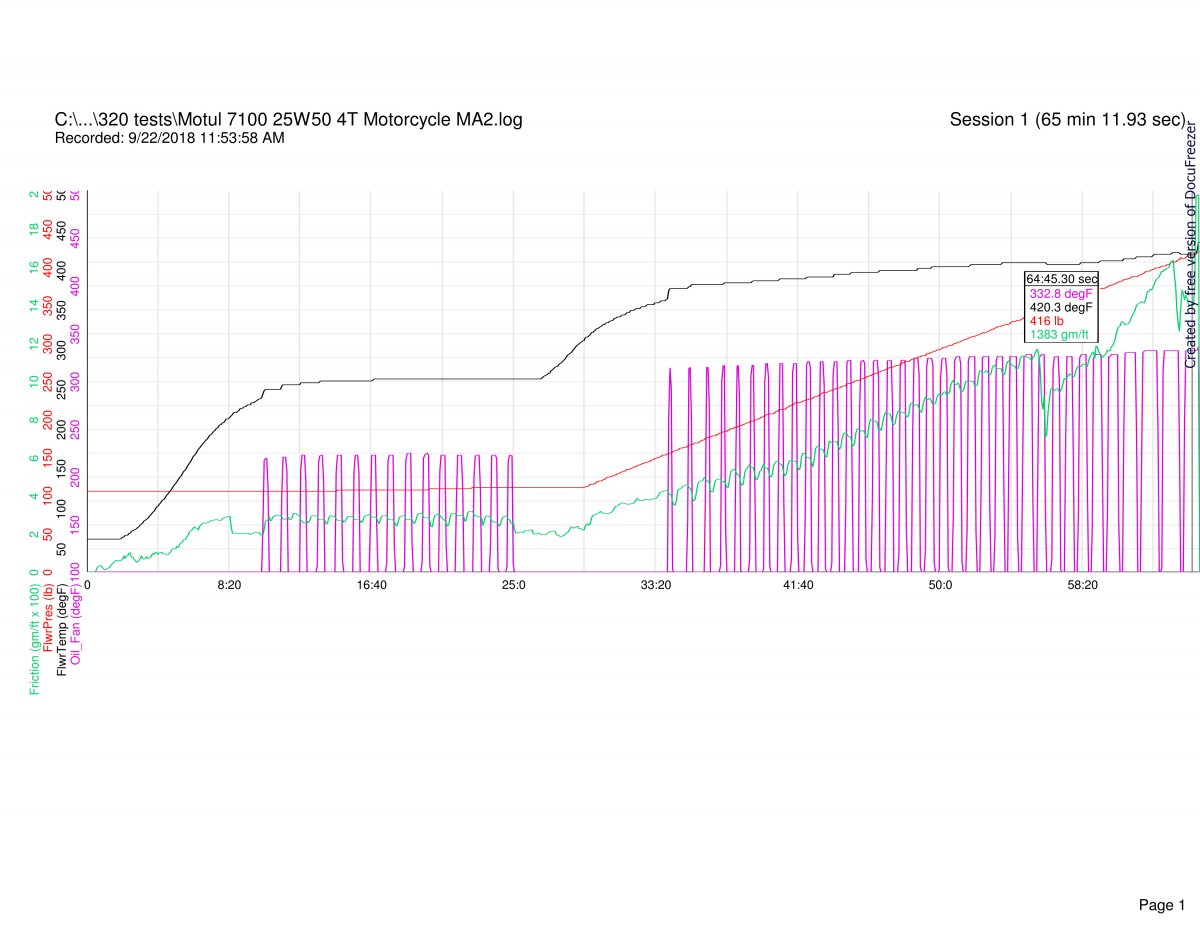

Motul_7100_20W50_4T_Motorcycle_Synthetic

416 lbs load

3.97 heat from high pressure shear

5.7 heat from friction

High heat from friction

Safe for wet clutches.

Good oil for Norton but it creates a lot of heat.

This is a computer generated number that replaces the cooling fan duty cycle which was sometimes affected by the length of the test.

I have edited the earlier results to show this. They will be edited in the database soon.

Less than 1 would be insignificant heat and friction -very good as long as this does not go along with a load rating that is too low.

~1 to 5 would be a good range in an air cooled motor.

10 would be severe heat.

Here are two more oils

___________________________________________________________

Motul_5100_15W50_4T_Motorcycle_Synthetic_blend

195 lbs load

3.47 heat from high pressure shear

4.9 heat from friction

Medium/ high heat from friction.

Safe for wet clutch

Good oil for Norton

__________________________________________________________

Motul_7100_20W50_4T_Motorcycle_Synthetic

416 lbs load

3.97 heat from high pressure shear

5.7 heat from friction

High heat from friction

Safe for wet clutches.

Good oil for Norton but it creates a lot of heat.

Last edited:

- Joined

- Jan 25, 2015

- Messages

- 45

Thanks for all your work Jim, donation sent. Jerry same same and membership done. Cheers.

- Joined

- Dec 10, 2008

- Messages

- 7,253

Jim, when you say heat from friction, are you talking about heat into the oil from external friction or heat generated by the viscous friction of the oil itself as it churns?

Thanks.

I am talking about the heat from the viscous friction. It makes the follower and arbor hot, along with the oil.

This heat is measured before there is any significant pressure on the follower. The follower is just surfing along on a wedge of oil.

It is measured between minutes 15 and 25 during the steady state part of the test.

Last edited:

- Joined

- Apr 15, 2009

- Messages

- 11,520

Jim, when you say heat from friction, are you talking about heat into the oil from external friction or heat generated by the viscous friction of the oil itself as it churns?

Thanks.

Pretty sure he means from the oil.

- Joined

- Dec 10, 2008

- Messages

- 7,253

Here is another oil.

_______________________________________________________________

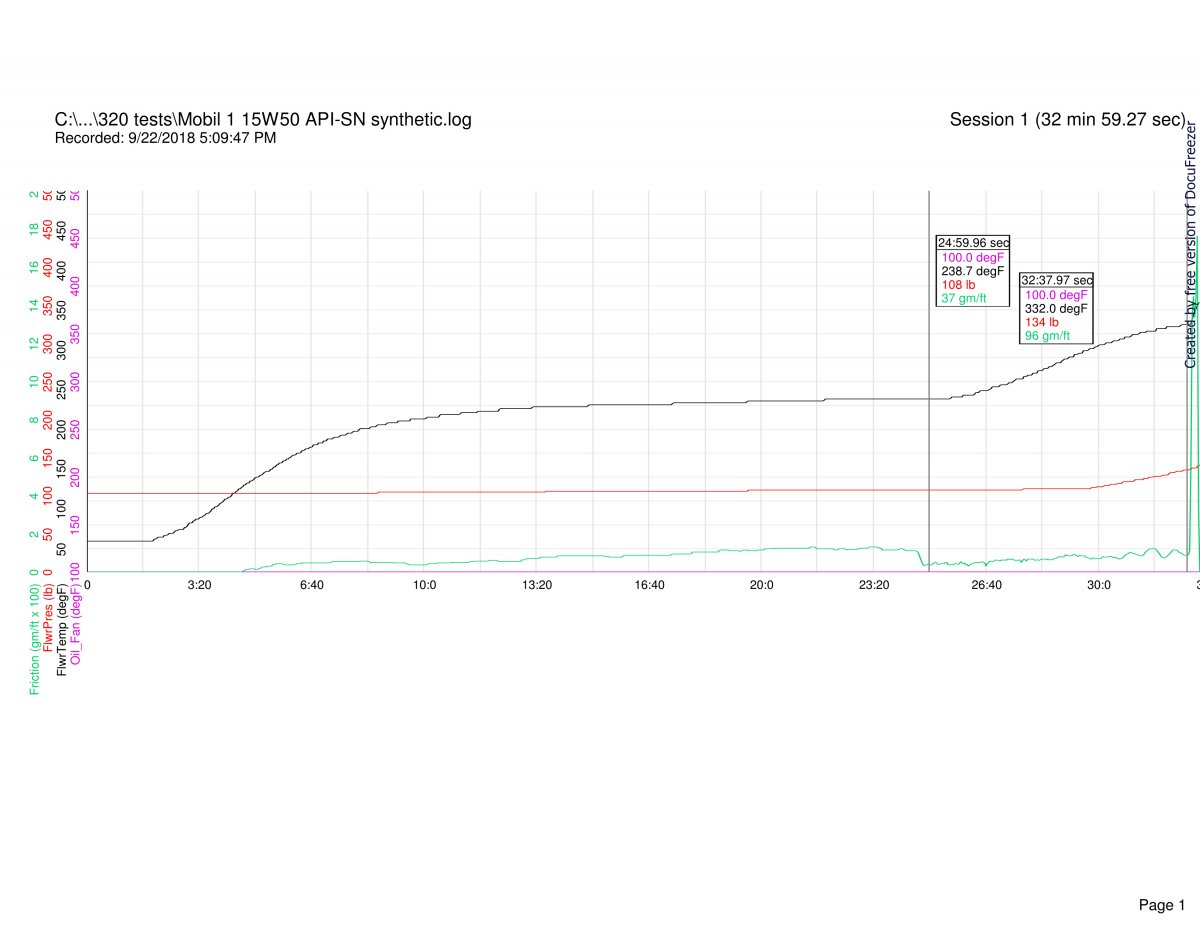

Mobil_1_15W50_API_SN_synthetic

134 lbs load

134 lbs load

No data for heat from high pressure shear

.009 heat from friction

Very low friction but gave up it's load capacity early when the temp went up.

Best used in a water cooled engine -as it was designed for.

Not safe for wet clutches.

_______________________________________________________________

Mobil_1_15W50_API_SN_synthetic

No data for heat from high pressure shear

.009 heat from friction

Very low friction but gave up it's load capacity early when the temp went up.

Best used in a water cooled engine -as it was designed for.

Not safe for wet clutches.

Last edited:

motorson

VIP MEMBER

- Joined

- Nov 29, 2011

- Messages

- 512

Thanks for letting me know. I rushed through making this. I have changed Mobil 1 to be ok for Nortons

Hi Jerry, the MPT 20w60 was deemed "excellent" in the original test (on page 25) with a follower failure pressure of 216 Lbs. Maybe the Bel-ray will end up being a better choice but I chose the one with good pressure tolerance as well as low temperature gain from friction.

- Joined

- Dec 10, 2008

- Messages

- 7,253

And the MPT is still probably the better choice for most users. The extreme pressure of the Bel Ray is not likely to be as much of an advantage as the lower friction would be on most engines.

But I do really like the Bel Ray with the friction reducer. I like the fact that I could not scar the follower, regardless of the pressure.

Of course this may change as I test more oils. There are still a lot of oils to test and I have no idea how they are going to do.

At least the test results are coming out solid now. There for a while I was getting some really strange results that didn't always make sense.

What led me to find the root of the problem was when I scrambled the dac firmware with the tig welder. When I was working to get it calibrated was when I found out something weird was happening with the process controller.

It turned out the firmware in it was not compatible with the options in the control.

That really affected the oils that had extra heat from friction because when it would switch to cooling mode it would turn on both the heater and the cooler in alternating fashion. But I could not see the heating element so I did not know it was not working right until I put a second themocouple in the pot to use for calibration.

Two more coming up soon.

And the VR1 oil looks much better now....it was one that was affected a lot since at least the conventional VR1 makes a lot of heat.

But I do really like the Bel Ray with the friction reducer. I like the fact that I could not scar the follower, regardless of the pressure.

Of course this may change as I test more oils. There are still a lot of oils to test and I have no idea how they are going to do.

At least the test results are coming out solid now. There for a while I was getting some really strange results that didn't always make sense.

What led me to find the root of the problem was when I scrambled the dac firmware with the tig welder. When I was working to get it calibrated was when I found out something weird was happening with the process controller.

It turned out the firmware in it was not compatible with the options in the control.

That really affected the oils that had extra heat from friction because when it would switch to cooling mode it would turn on both the heater and the cooler in alternating fashion. But I could not see the heating element so I did not know it was not working right until I put a second themocouple in the pot to use for calibration.

Two more coming up soon.

And the VR1 oil looks much better now....it was one that was affected a lot since at least the conventional VR1 makes a lot of heat.

Last edited:

- Joined

- Dec 10, 2008

- Messages

- 7,253

___________________________________________________________

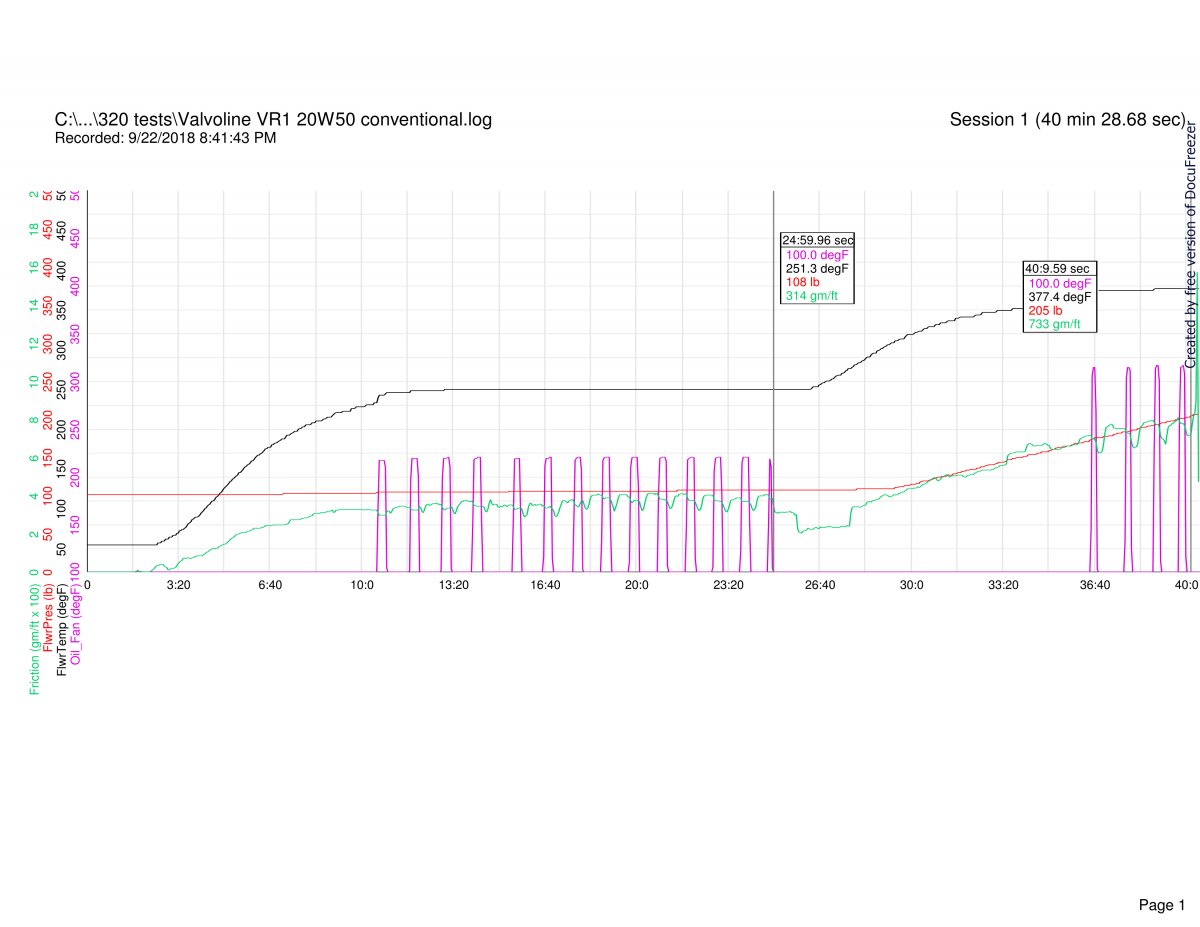

Valvoline_VR1_20W50_conventional

205 lbs Load

3.22 heat from high pressure shear

4.23 heat from friction

Medium/high heat from friction

Not made for a wet clutch but likely OK

__________________________________________________________

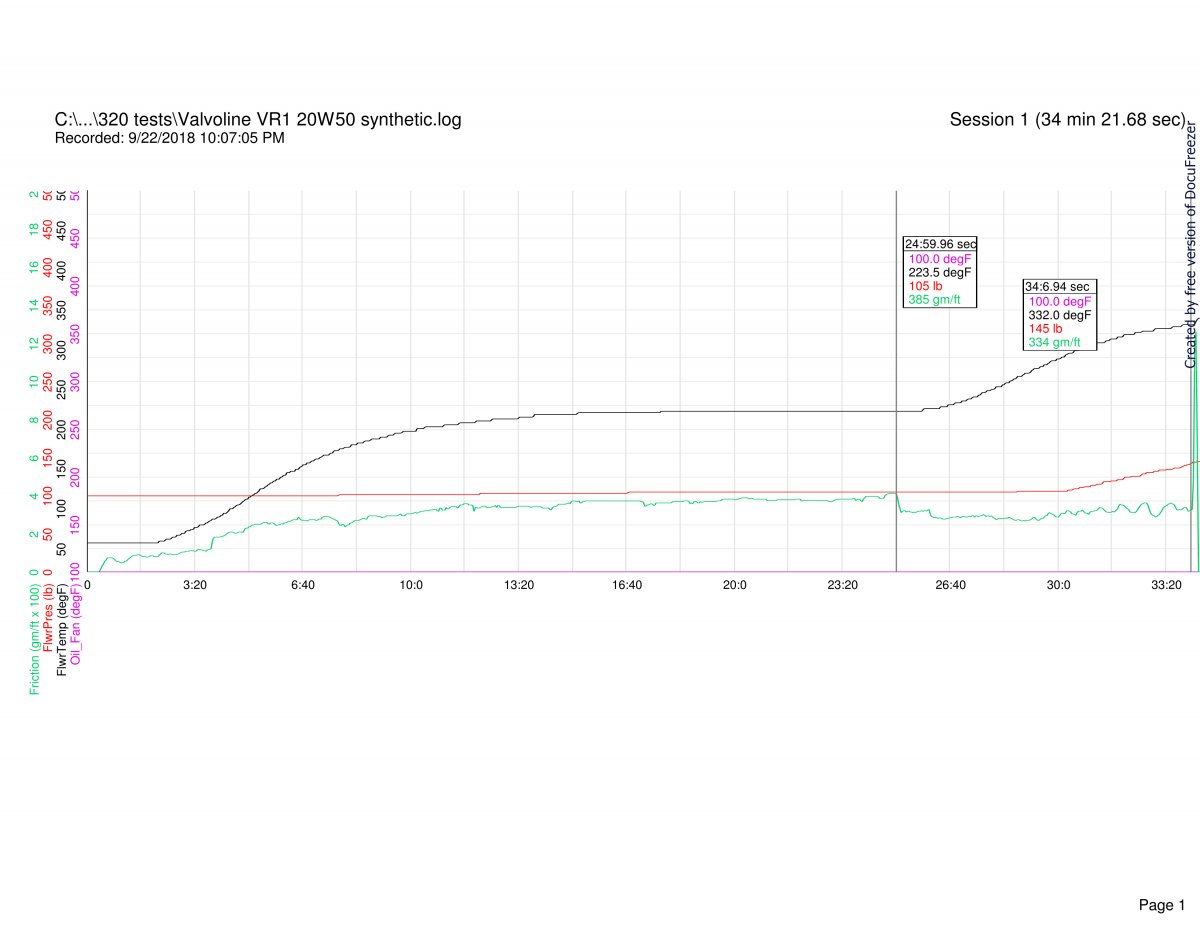

Valvoline_VR1_20W50_synthetic

145 lbs load

No data for heat from high pressure shear

.003 heat from friction

Very low heat from friction -to bad the load capacity went down with it.

Not suitable for a wet clutch

Valvoline_VR1_20W50_conventional

205 lbs Load

3.22 heat from high pressure shear

4.23 heat from friction

Medium/high heat from friction

Not made for a wet clutch but likely OK

__________________________________________________________

Valvoline_VR1_20W50_synthetic

145 lbs load

No data for heat from high pressure shear

.003 heat from friction

Very low heat from friction -to bad the load capacity went down with it.

Not suitable for a wet clutch

Last edited:

Brooking 850

VIP MEMBER

- Joined

- Oct 3, 2011

- Messages

- 1,609

Hi Jim , curious to know if that Driven HD 50 would fare better under the revised test method or are you happy with the original test result?

Ive just been out for a spirited ride on our back road hilly twisties over 250 km and ran the temp gauge over all spots on the hot motor once I got back as the motor has had a freshen up with rings and big ends and given the head a Vv's a touch up as well.

Crank case bottom RHS was 68* C and oil in tank was 70* C Head temp was 115* C at the spindle covers.

I am using that Torco MPZ TR1 10W40

Regards Mike

Ive just been out for a spirited ride on our back road hilly twisties over 250 km and ran the temp gauge over all spots on the hot motor once I got back as the motor has had a freshen up with rings and big ends and given the head a Vv's a touch up as well.

Crank case bottom RHS was 68* C and oil in tank was 70* C Head temp was 115* C at the spindle covers.

I am using that Torco MPZ TR1 10W40

Regards Mike

- Status

- Not open for further replies.