- Joined

- May 28, 2003

- Messages

- 2,590

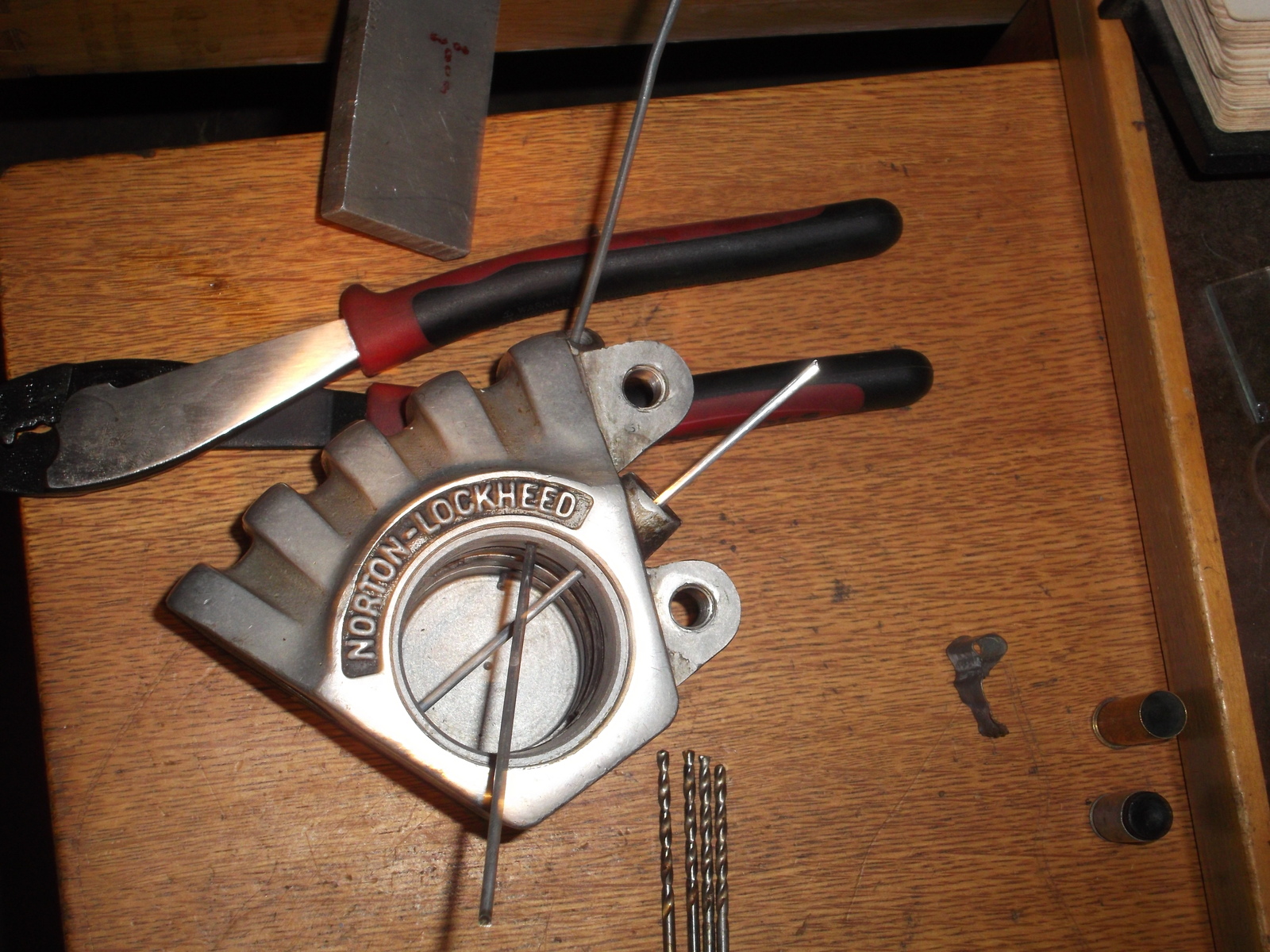

For those who have trouble dismantleing the Norton/Lockheed caliper, these few words might help...

Note the three passage drillings.

One entrance port for the brake fluid going into the outer piston bore.

Second drilling to connect the front bore to the bleeder passage.

Third drilling from the Bleeder down to the rear piston bore, while also completing the interconnect between the outer to inner bore.

Make sure that a #31 drill (smaller than 1/8"? will pass down all 3 drillings ( especially troublesome is the rear one.

Failure to insure all 3 are clear has caused the caliper to split, at around 2500PSI when attempting to use the hydraulic extraction method . The bleeder passage to rear piston was jam full of water based DOT3 aluminum corrosion.

The passage was cleared and a port for the hydraulic fitting was drill and /tapped to complete the hydraulic piston removal.

The pressure in the outer piston pressing on the 1/4" steel plate and the blockage in the passage prevented rear piston movement. BANG

To remind you that pneumatic pressure is dangerous for piston removal, but can succeed when there are no major hang ups.

Heavy duty hydraulic has never failed when the passages are cleared.

Note the three passage drillings.

One entrance port for the brake fluid going into the outer piston bore.

Second drilling to connect the front bore to the bleeder passage.

Third drilling from the Bleeder down to the rear piston bore, while also completing the interconnect between the outer to inner bore.

Make sure that a #31 drill (smaller than 1/8"? will pass down all 3 drillings ( especially troublesome is the rear one.

Failure to insure all 3 are clear has caused the caliper to split, at around 2500PSI when attempting to use the hydraulic extraction method . The bleeder passage to rear piston was jam full of water based DOT3 aluminum corrosion.

The passage was cleared and a port for the hydraulic fitting was drill and /tapped to complete the hydraulic piston removal.

The pressure in the outer piston pressing on the 1/4" steel plate and the blockage in the passage prevented rear piston movement. BANG

To remind you that pneumatic pressure is dangerous for piston removal, but can succeed when there are no major hang ups.

Heavy duty hydraulic has never failed when the passages are cleared.