- Joined

- Apr 15, 2009

- Messages

- 11,520

Have we ever had a clutch thread? No? Didn't think so.

So I was getting a little weeping from the primary on my Interstate. No belt drive. Not yet.

When I was in there I noticed a bit of play with the clutch basket. Going the cheapest route I replaced the bearing. That snugged it up a little bit. I really suspect a warn clutch hub center.

Then of course there was the issue with the plates. I remember when I first got the bike I think it had the bronze plates. At some point they were replaced with Barnetts.

Well, they didn't look good.

Now I have new plates in there and I'm checking the pull. It's slightly better than before (which wasn't great). Most interestingly was the old plates were the same thickness, so no apparent wear at all. Well, aside from the teeth.

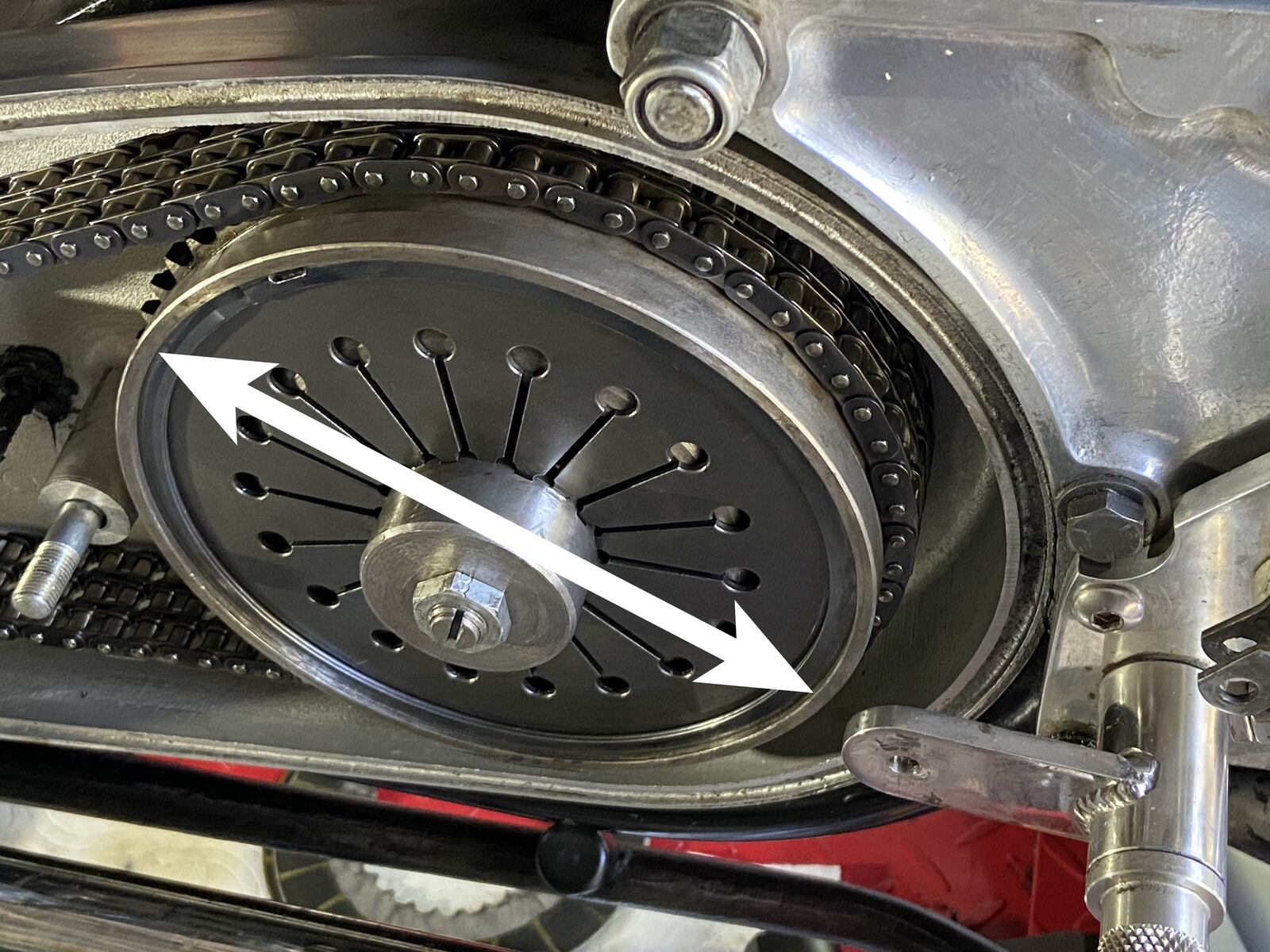

So with the new plates this is what the clutch looks like. That doesn't seem right as there's no room for lift, right?

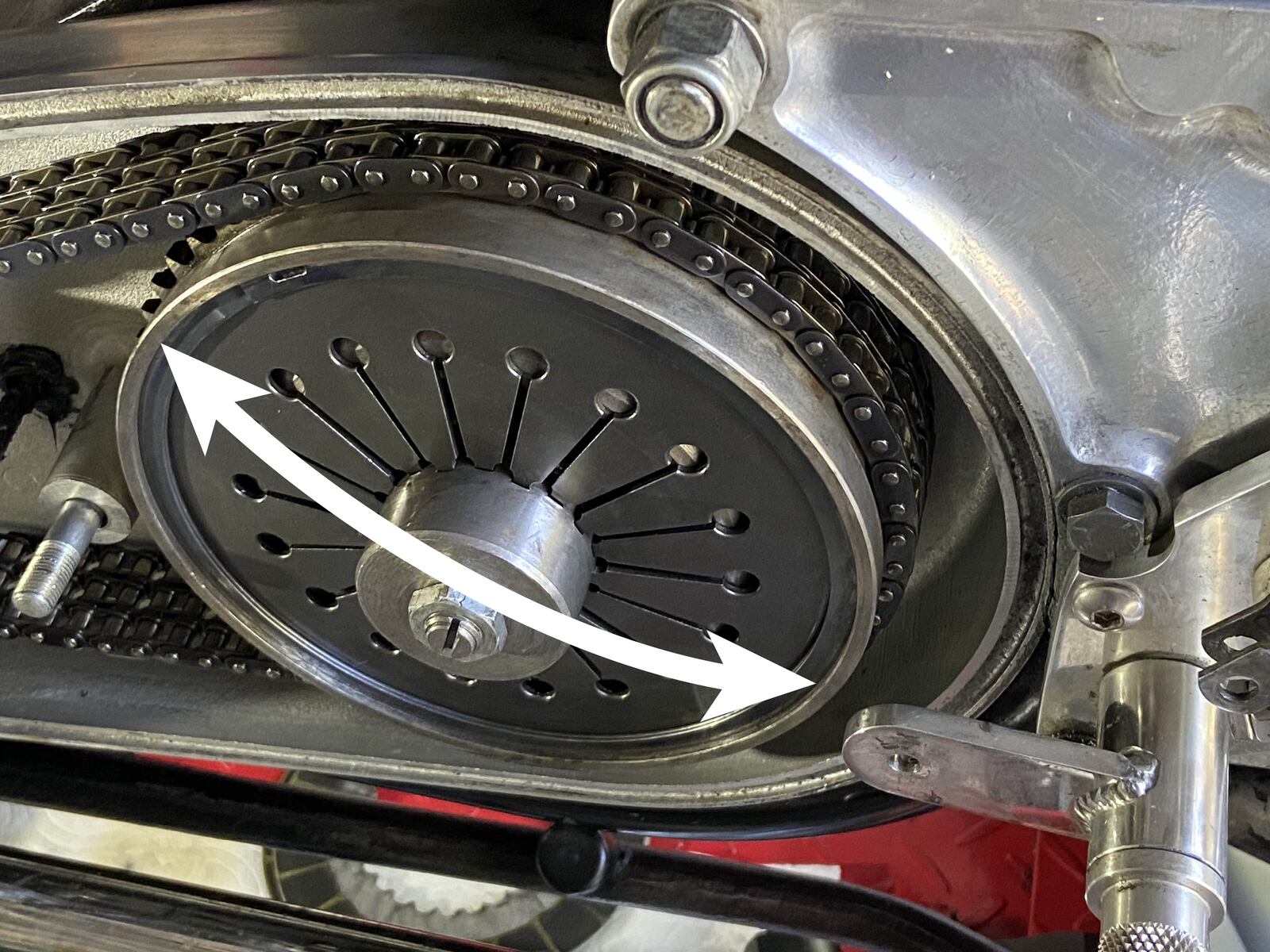

But then when we look at the spring it's flat (as much as I can tell) when engaged. All my reading says that it should be slightly inverted or flat. So I think it's right where it should be.

When I check out my 750 which has the perfect clutch it's actually extended (dished in) slightly when engaged (which would indicate a shorter stack height).

The best I can tell is that I need to lower the stack height on the 850. Do I have this right?

So I was getting a little weeping from the primary on my Interstate. No belt drive. Not yet.

When I was in there I noticed a bit of play with the clutch basket. Going the cheapest route I replaced the bearing. That snugged it up a little bit. I really suspect a warn clutch hub center.

Then of course there was the issue with the plates. I remember when I first got the bike I think it had the bronze plates. At some point they were replaced with Barnetts.

Well, they didn't look good.

Now I have new plates in there and I'm checking the pull. It's slightly better than before (which wasn't great). Most interestingly was the old plates were the same thickness, so no apparent wear at all. Well, aside from the teeth.

So with the new plates this is what the clutch looks like. That doesn't seem right as there's no room for lift, right?

But then when we look at the spring it's flat (as much as I can tell) when engaged. All my reading says that it should be slightly inverted or flat. So I think it's right where it should be.

When I check out my 750 which has the perfect clutch it's actually extended (dished in) slightly when engaged (which would indicate a shorter stack height).

The best I can tell is that I need to lower the stack height on the 850. Do I have this right?