Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,673

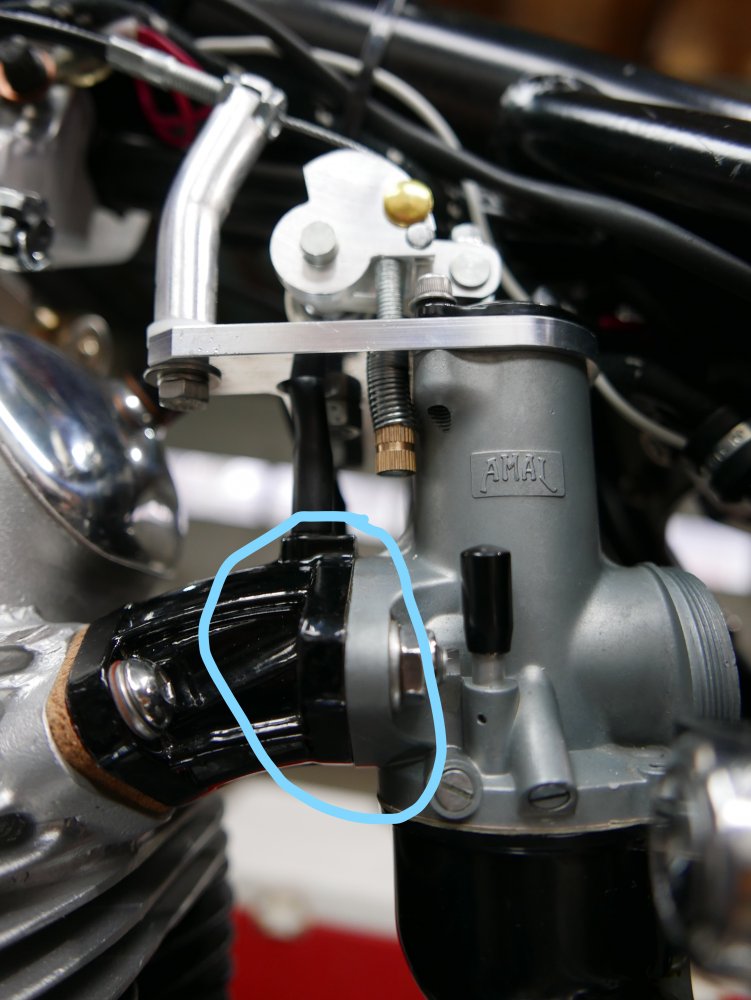

I have read and received various recommendations in regards to creating a good seal between the carb body and the intake runner.

Some say the O-ring works fine, others say a good fiber gasket material and still others recommend filling the O-ring groove with one of the various gasket forming offerings, usually in a tube.

How did you connect your setup?

Some say the O-ring works fine, others say a good fiber gasket material and still others recommend filling the O-ring groove with one of the various gasket forming offerings, usually in a tube.

How did you connect your setup?