p400

VIP MEMBER

- Joined

- Jul 14, 2014

- Messages

- 1,289

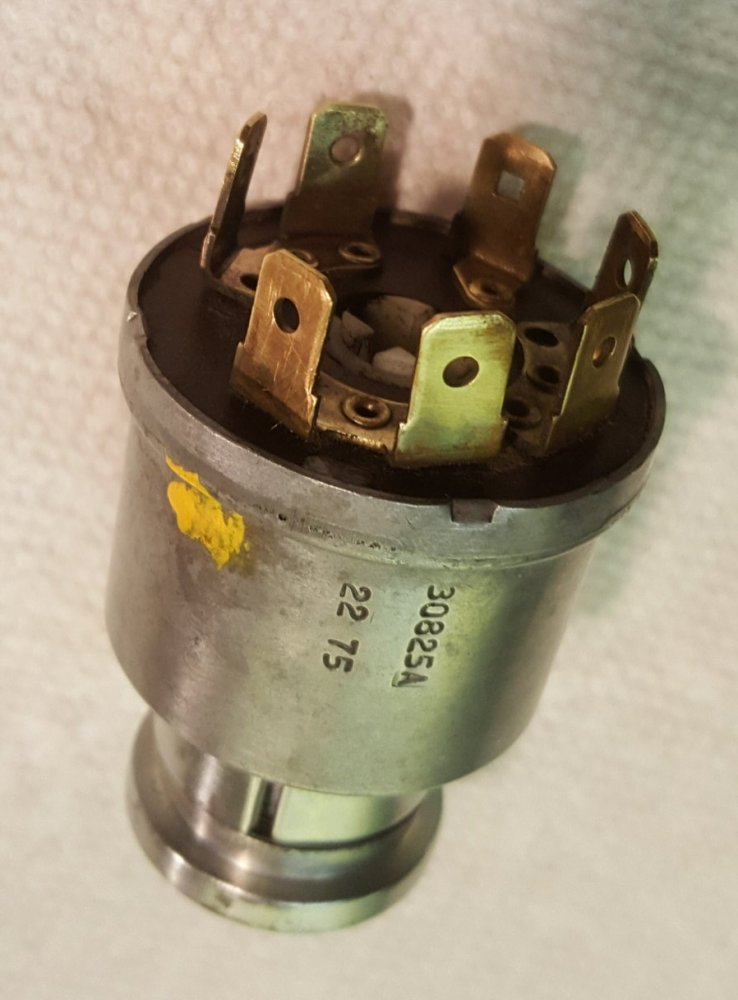

I was disappointed with my new ignition switch installed on my Canadian Mk3 and had come to the realization that maybe a closer look at my now shelved 30825A original switch was now the best solution. It is a standard construction Lucas rotary switch spring loaded and staked together.

Externally it cleaned up very well and you can see the four stake locations.

Externally it cleaned up very well and you can see the four stake locations.